Space Synthetic Biology

Microbial biomanufacturing in space focuses on the development of a platform technology named BioNutrients that uses food microorganisms to produce human nutrients during long-duration space missions. This system could also be developed to produce other high-value compounds such as medicines. The CO2-Based Manufacturing, involves constructing a system that makes media for microbial biomanufacturing using in situ resources such as CO2 and water, as well as making space-relevant bioreactors and engineered organisms to make needed products.

Lead Center

Ames Research Center

Introduced

October 2018

Principal Technologist

James Broyan

Andrew Abercromby

Project Manager

Frances Donovan

BioNutrients: A Five-Year Experiment in Space Nears Completion

NASA’s bio-manufacturing experiment called BioNutrients is testing a way to use microorganisms to produce on-demand nutrients that will be critical for human…

Read the Story

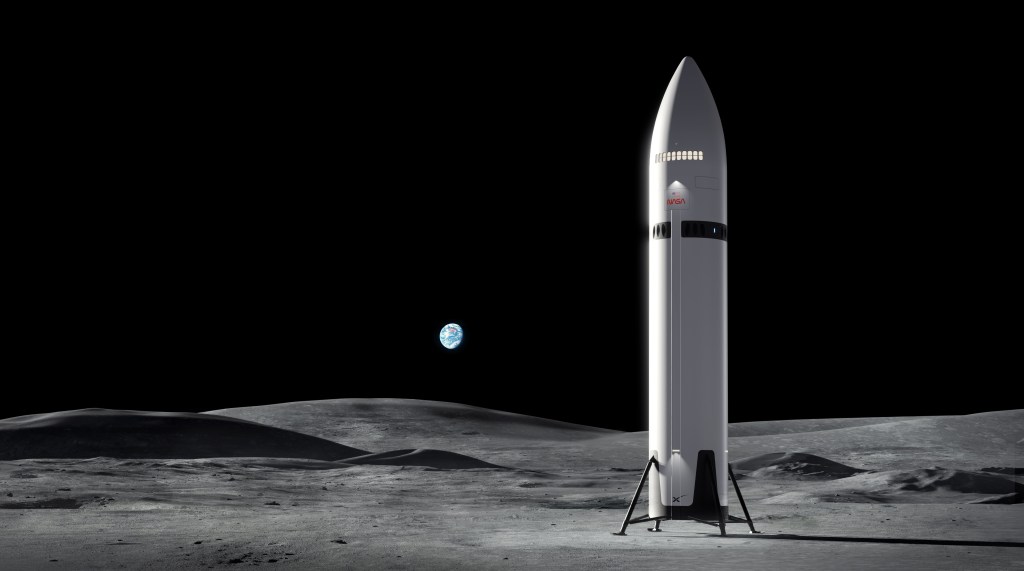

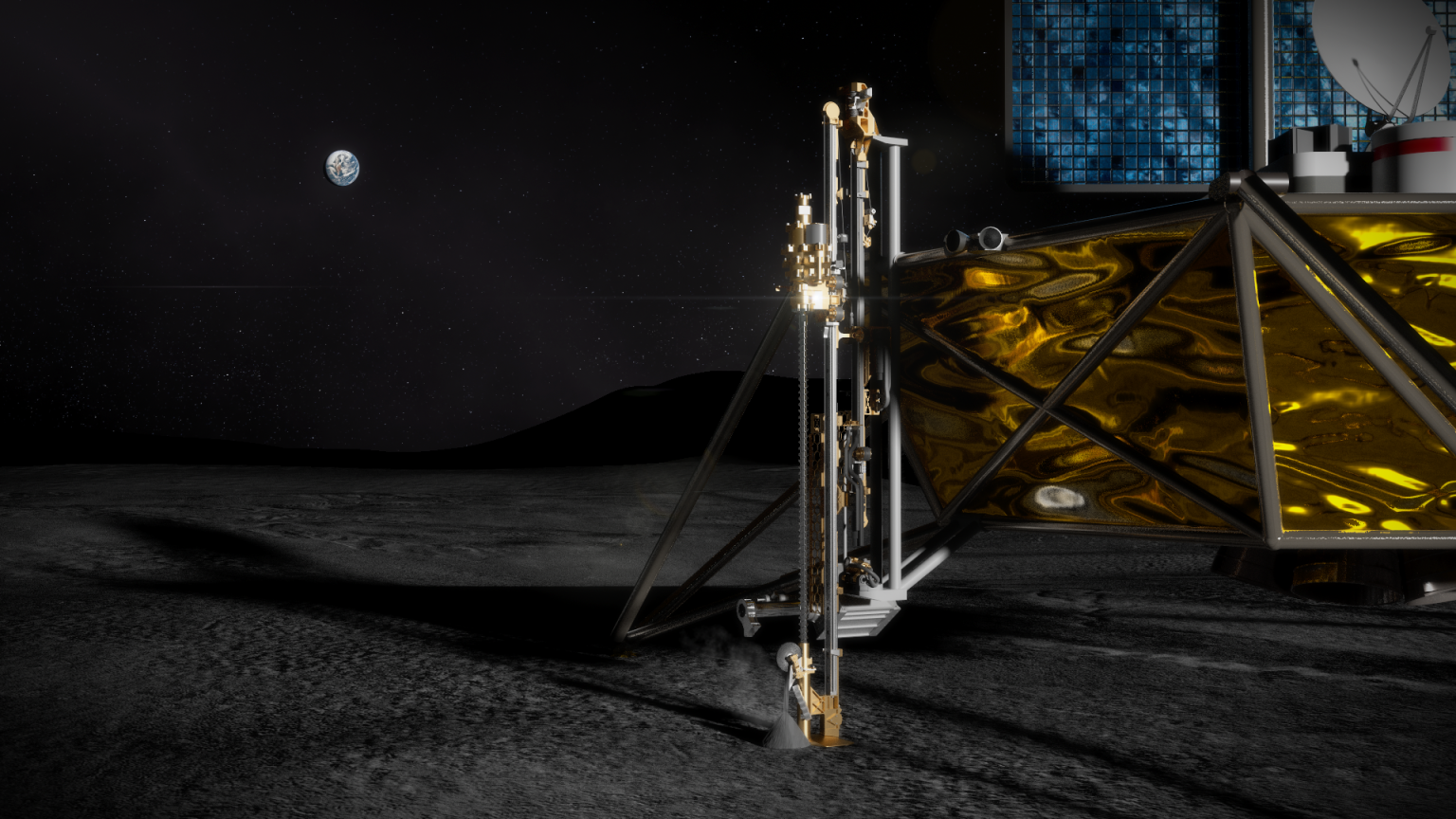

In the future, NASA’s long-duration lunar and Mars missions will require that we minimize the amounts of supplies launched, increase reuse and recycling, and use local resources to make crucial products for the crew. When possible, we want to make it there, not take it there.

The Space Synthetic Biology (SynBio) project, located at NASA’s Ames Research Center in California’s Silicon Valley, is developing technologies to biomanufacture valuable products on-demand such as vitamins and medicines. In addition, biomanufacturing processes will allow crews to produce valuable materials, such as a healthy fats, proteins and even a form of cement, from local resources.

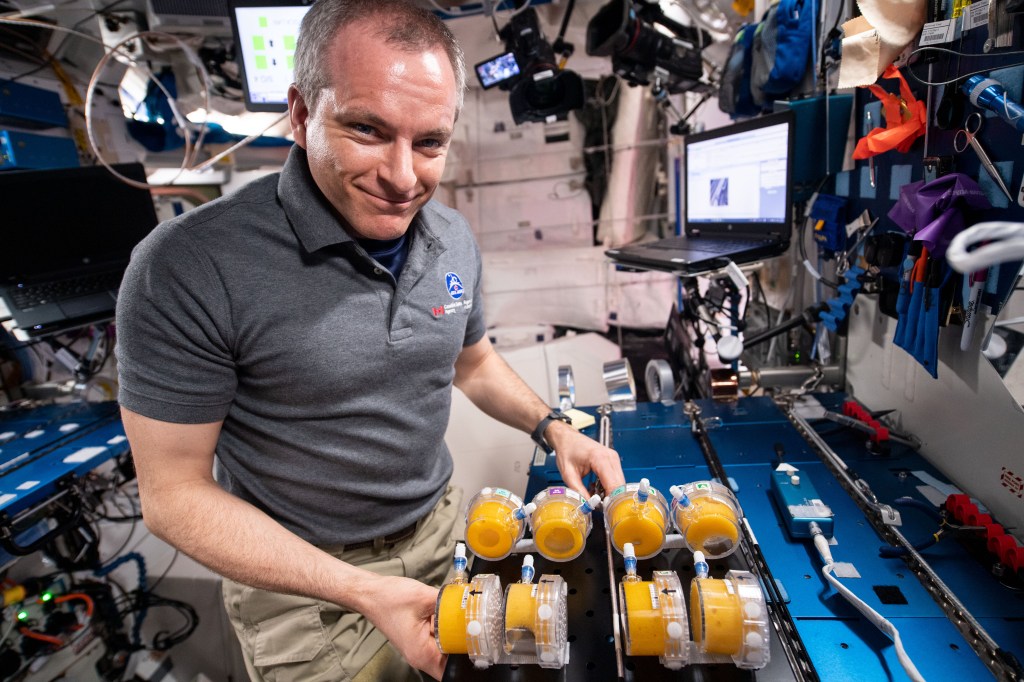

The BioNutrients experiment is part of NASA’s SynBio project and will test an in-space nutrient production method that uses genetically-engineered baker’s yeast and an extended shelf-life growth substrate to produce specific antioxidants, such as beta carotene and zeaxanthin, typically found in carrots, bell peppers and other vegetables. In April 2019, the SynBio team launched their first batch of “BioNutrient” packs to the International Space Station for a five-year experiment. The BioNutrient packs are filled with dehydrated yeast and their food source. To initiate the tests, astronauts aboard the space station add sterile water to the pack, mix well and keep the packet warm for 48 hours. Then, they freeze it to be analyzed later, back on Earth. NASA scientists will check how the system performed, including how much yeast grew in the packets and how much nutrient the experiment produced.

The SynBio project team is also developing a technology that chemically converts carbon dioxide (CO2) and water to organic compounds that can “feed” microbial biomanufacturing systems to make a wide range of products such as food, medicines and plastics. This same method could be widely applied to sustainably create these products on Earth.

To further advance these efforts, NASA’s Space Technology Mission Directorate asked scientists and engineers across the country to convert CO2 to molecules to enable biomanufacturing in space. These synthetic biology technologies will be an important part of astronaut health and the sustainability of future NASA missions to the Moon and beyond.

Partners:

Under SynBio, the CO2-Based Manufacturing task, Dr. Matthew Kanan of Stanford University is developing an electrochemical process for the conversion of carbon monoxide and carbon dioxide to acetate and other organic products.

Learn more: