Bulk Metallic Glass Gear

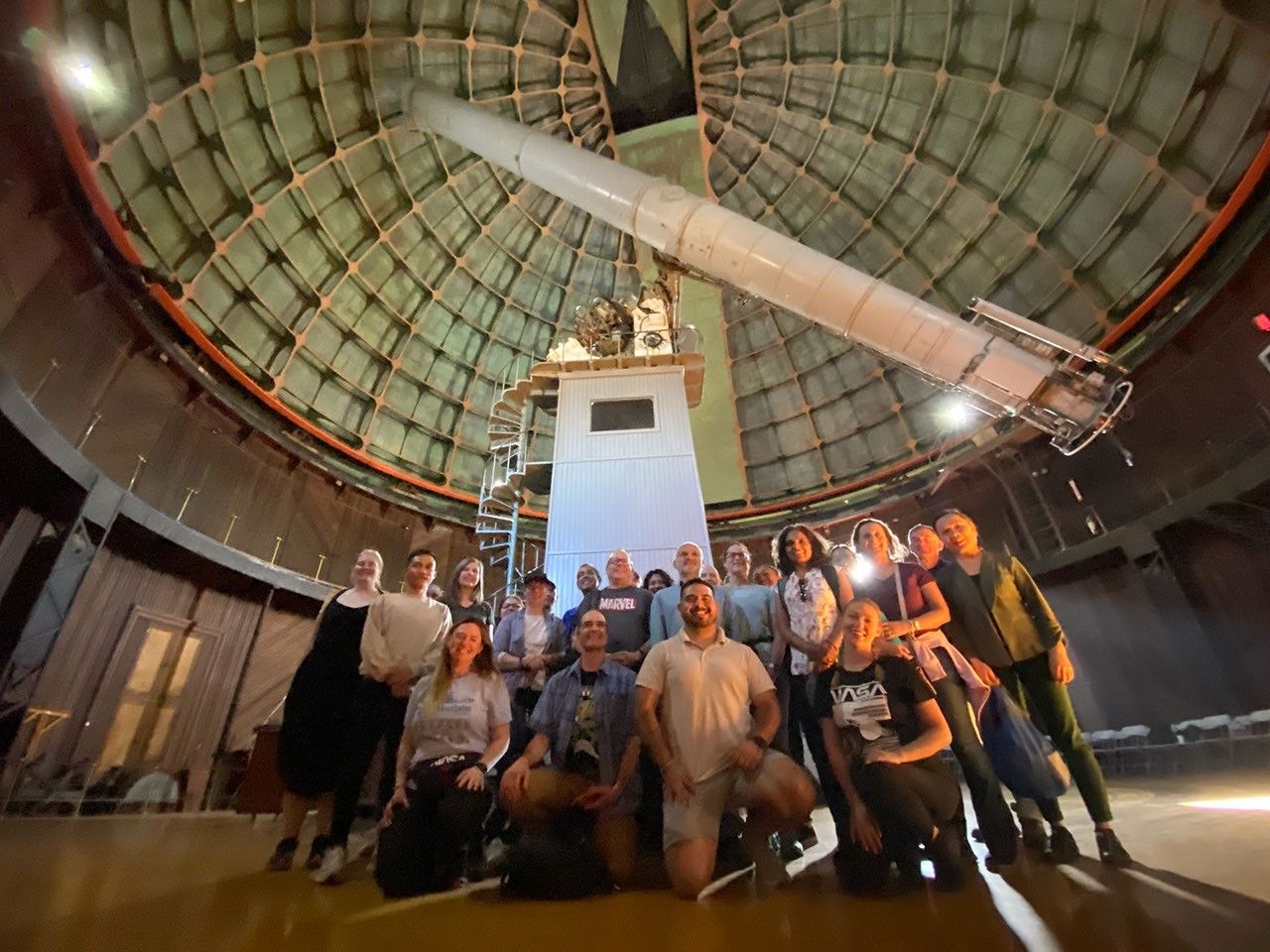

NASA’s Bulk Metallic Glass Gear (BMGG) project is developing technologies that could be the nuts and bolts of missions to explore destinations throughout the solar system, from the Moon to Mars to the icy worlds such as Jupiter’s moon, Europa.

Lead Center

Jet Propulsion Laboratory

Introduced

October 2015

Principal Technologist

Mark Hilburger

Project Manager

Peter Dillon

NASA’s Bulk Metallic Glass Gear (BMGG) project is developing technologies that could be the nuts and bolts of missions to explore destinations throughout the solar system, from the Moon to Mars to the icy worlds such as Jupiter’s moon, Europa. These locations have extreme environments that require technologies to operate at temperatures below –238 degrees Fahrenheit (–150 degrees Celsius). To put that in perspective, the lowest recorded temperature at any location on Earth’s surface was -144 degrees Fahrenheit) (- 97.8 degrees Celsius) in small topographic basins near the East Antarctic ice divide.

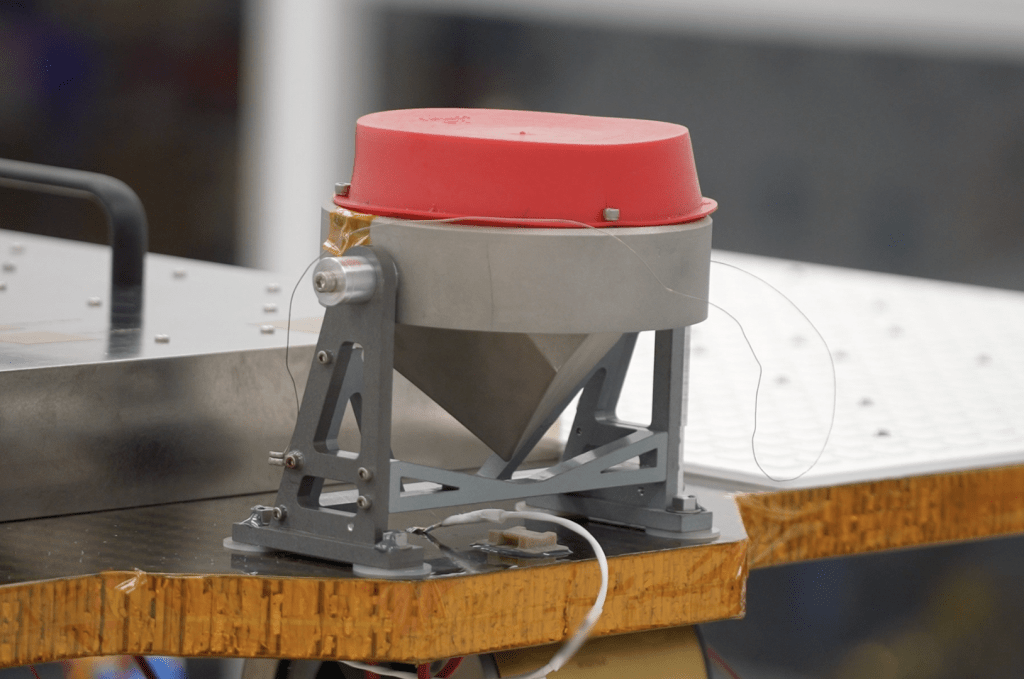

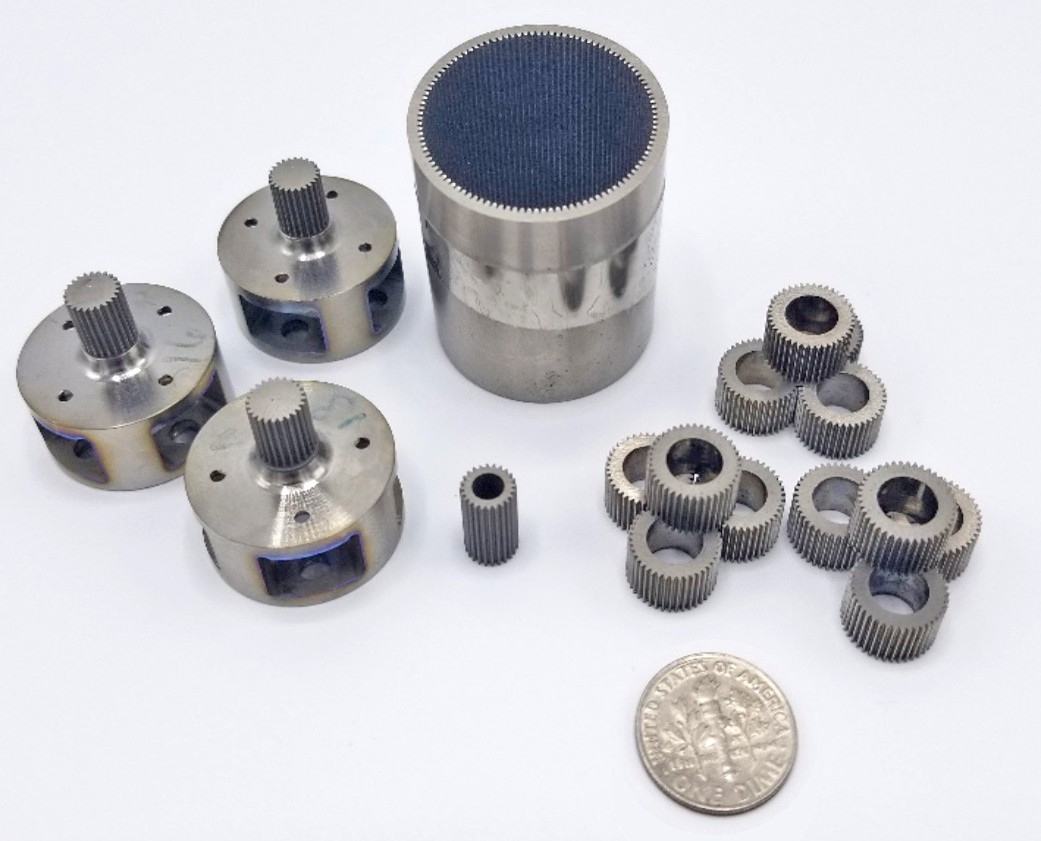

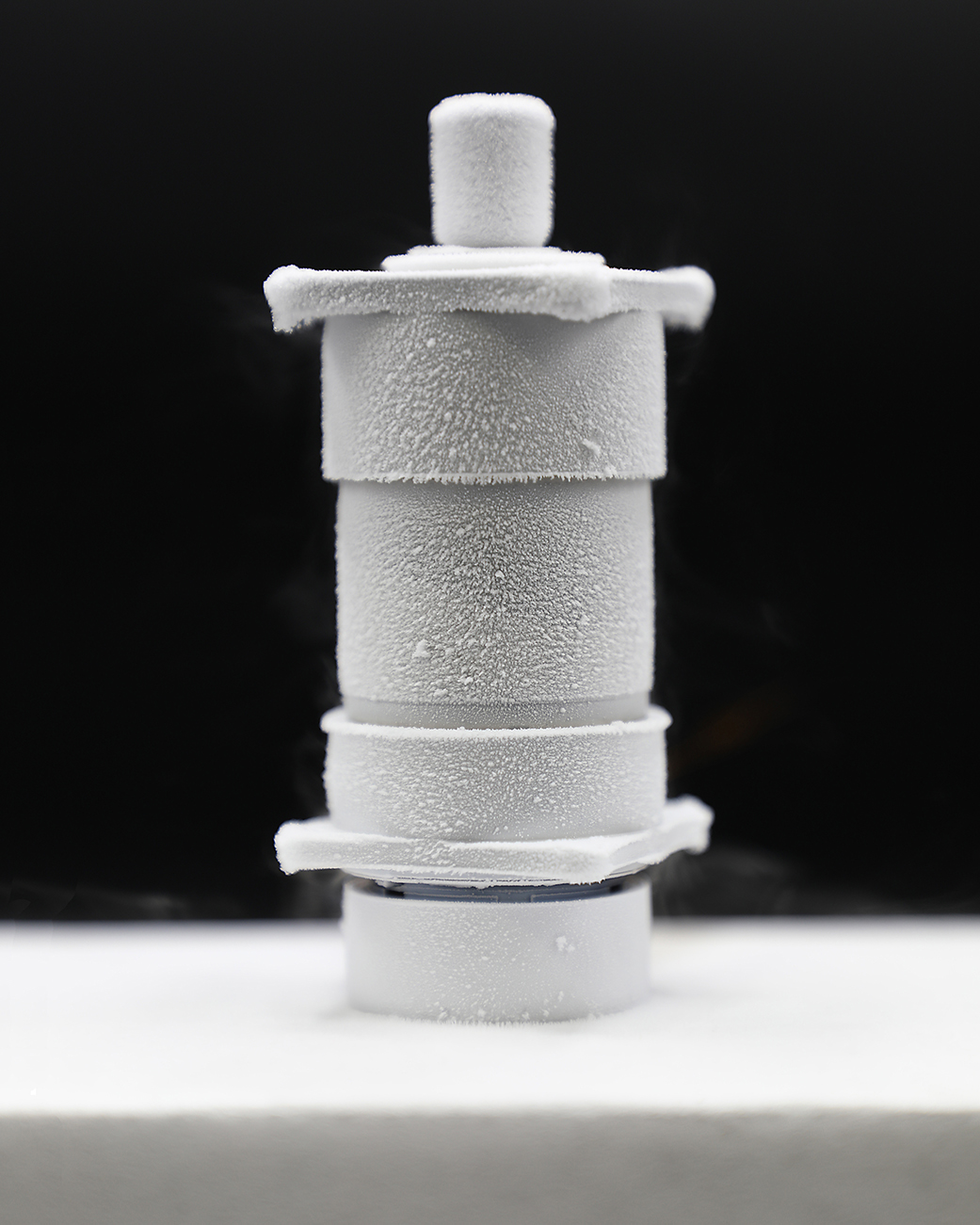

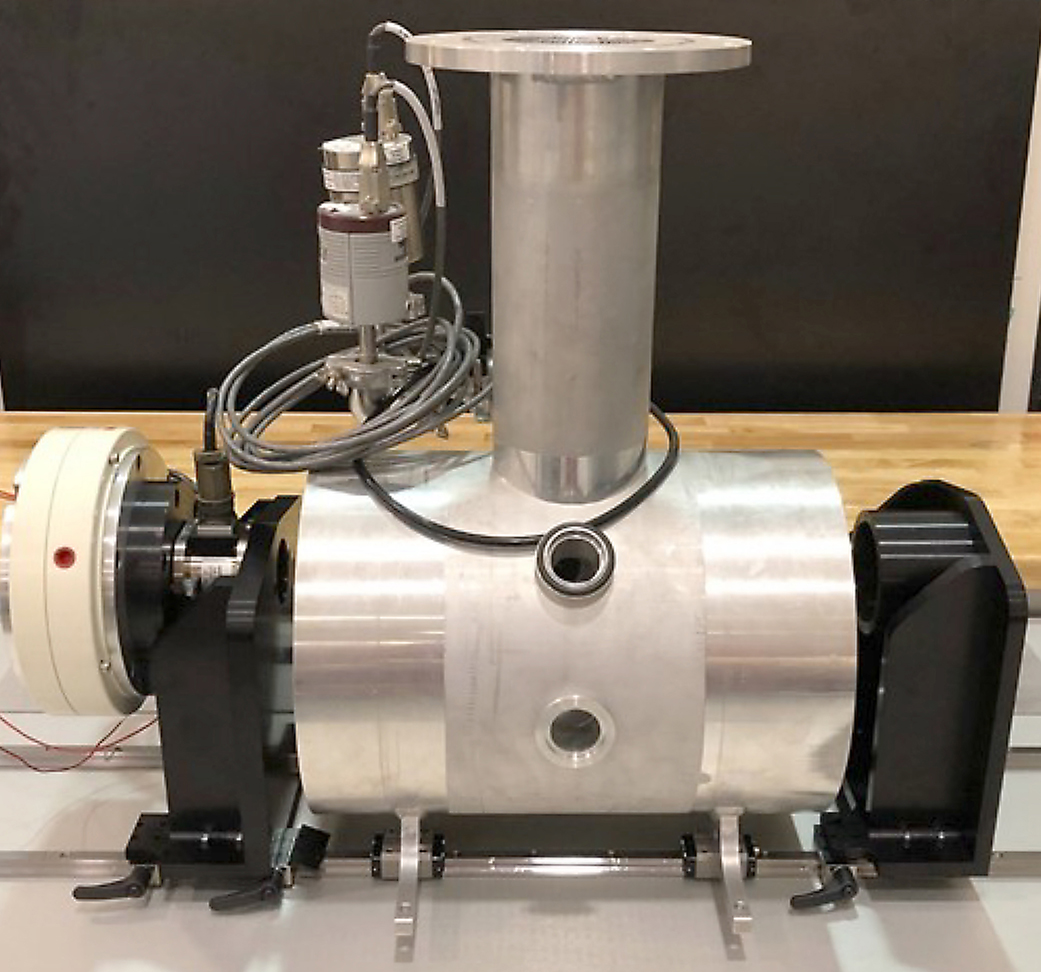

Researchers are developing special gearboxes that can operate in these extreme environments. A gearbox is a mechanical unit or component comprised of integrated gears within a housing or casing. Typically, in extremely low temperatures, gearboxes require a source of heating and lubrication to prevent the gears from breaking or snapping. However, the BMGG project team is creating alloys made of “metallic glass” for gearboxes to survive extreme environments without heating and lubricant. Metallic glass is a solid metallic material with disordered atomic-scale structure. The unique composition and amorphous atomic structure of the BMGG metallic glass alloys make them tougher than ceramics and twice as strong as steel, with better elastic properties than both.

Gearboxes developed with this bulk metallic glass technology are capable of operating at surface temperatures of –173 °C (–280 °F). Combined with greater wear and corrosion resistance, these alloys are promising gearbox component materials.

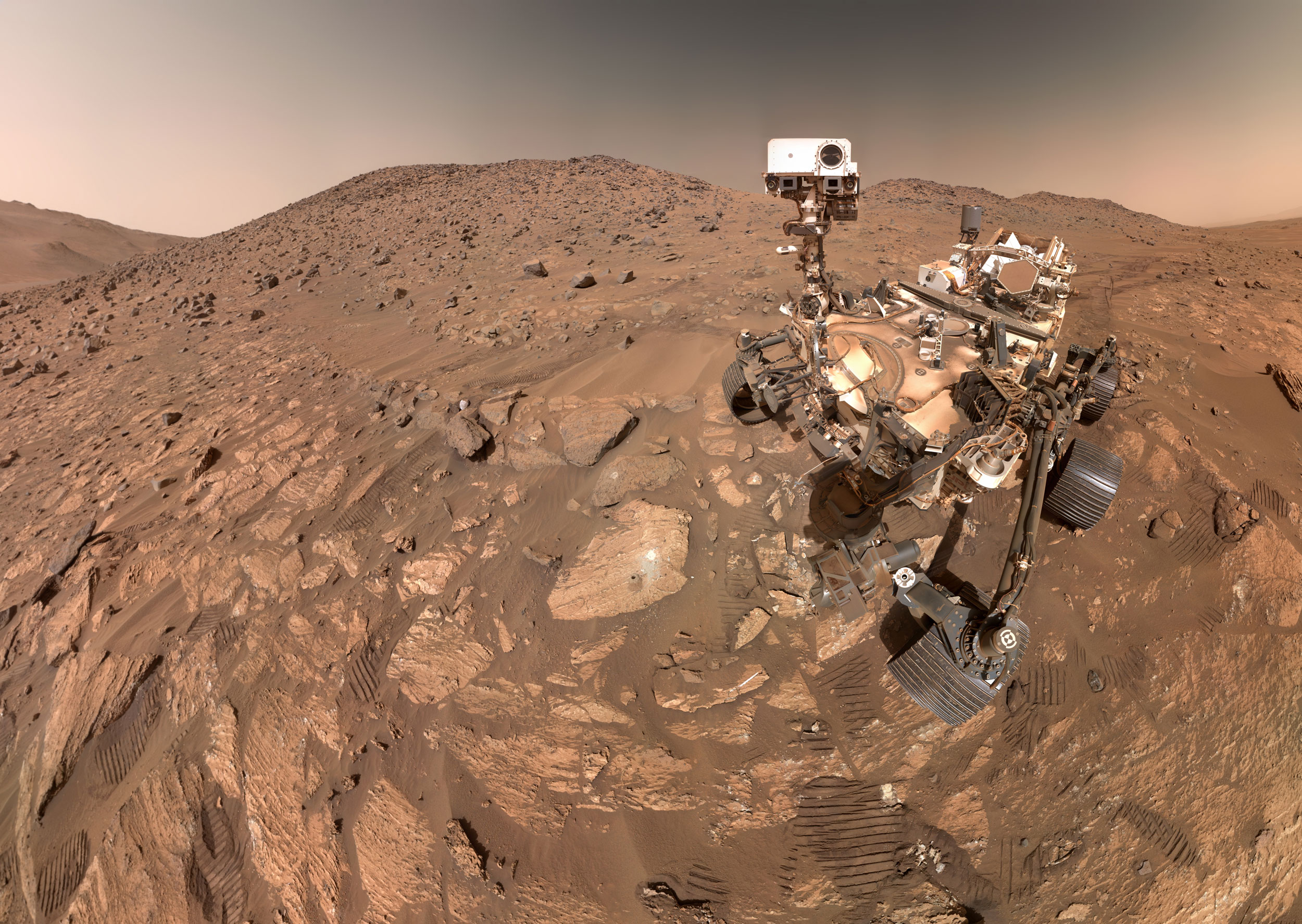

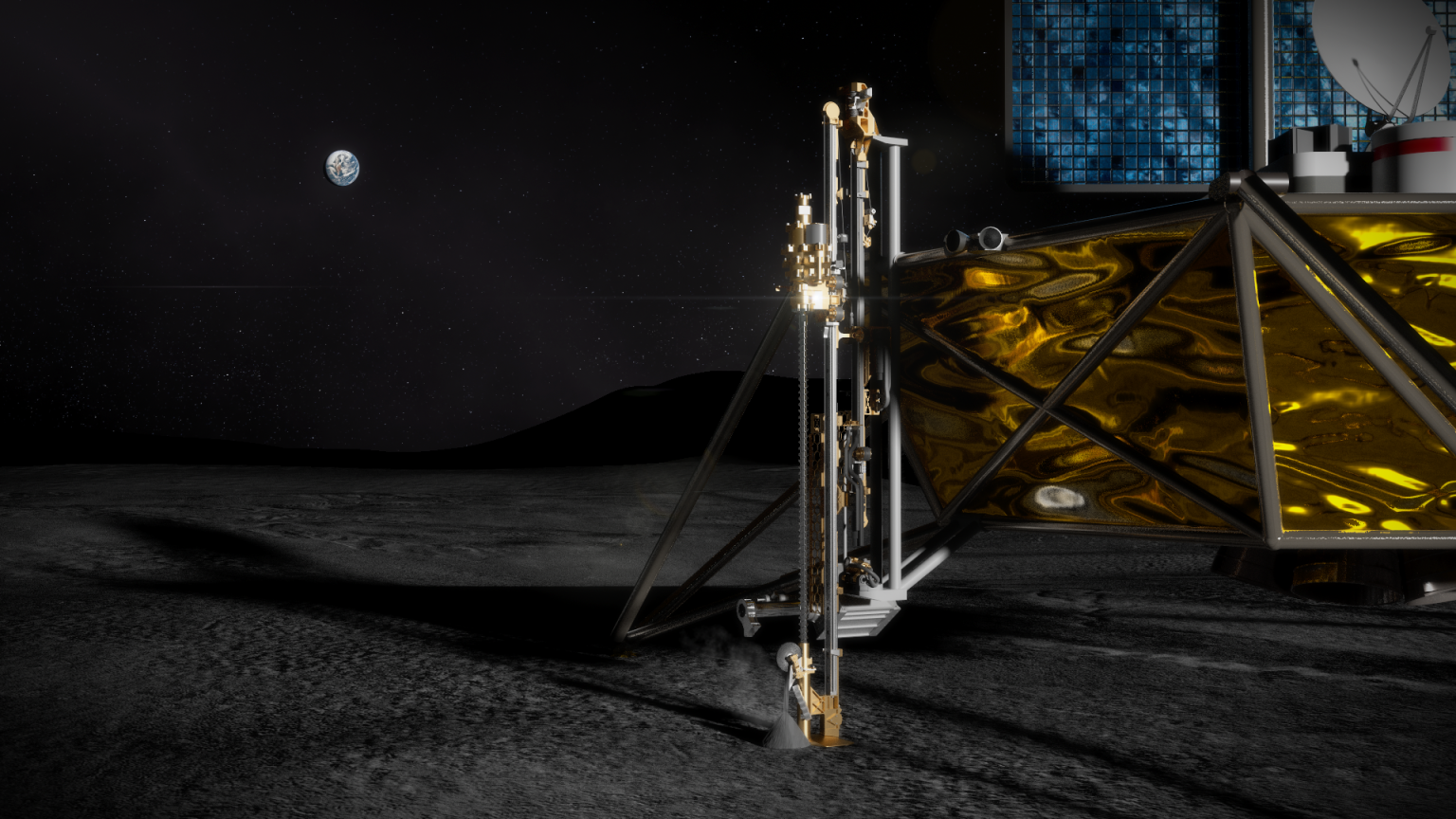

This project plans to demonstrate capabilities of custom bulk metallic glass alloys in heater-free gearbox configurations. These heater-free gearboxes could increase science return for in-space missions by reducing power consumption, mass, system complexity, and operational constraints. If applied to a Mars rover, for example, this technology could enable nighttime operations while saving enough power to run its remote sensing mast while moving. The additional benefit of 15.4 lbs (~7 kg) in mass savings could make room for another instrument.

NASA is working closely with industry to develop material specifications to mature a supply chain for the bulk metallic glass alloys. Recently, the project demonstrated a heat-free planetary gearbox comprised of metallic glass gear components operating at and below –173 °C (–280 °F). Additionally, the project will demonstrate the metallic glass gears’ resilience to launch, entry, descent and landing loads.

The project seeks to advance bulk metallic glass gears for future in-space demonstration opportunities and mission use.

Partners

- Eutectix of Chatham, N.J., is manufacturing the bulk metallic gear alloy feedstock for BMGG in their Tolleson, AZ facility

- Supercool Metals of Branford, CT. is making the strain wave gear flexsplines for the project

- Visser Precision, of Denver, CO, is fabricating the planetary gearbox components through a manufacturing process called direct injection molding