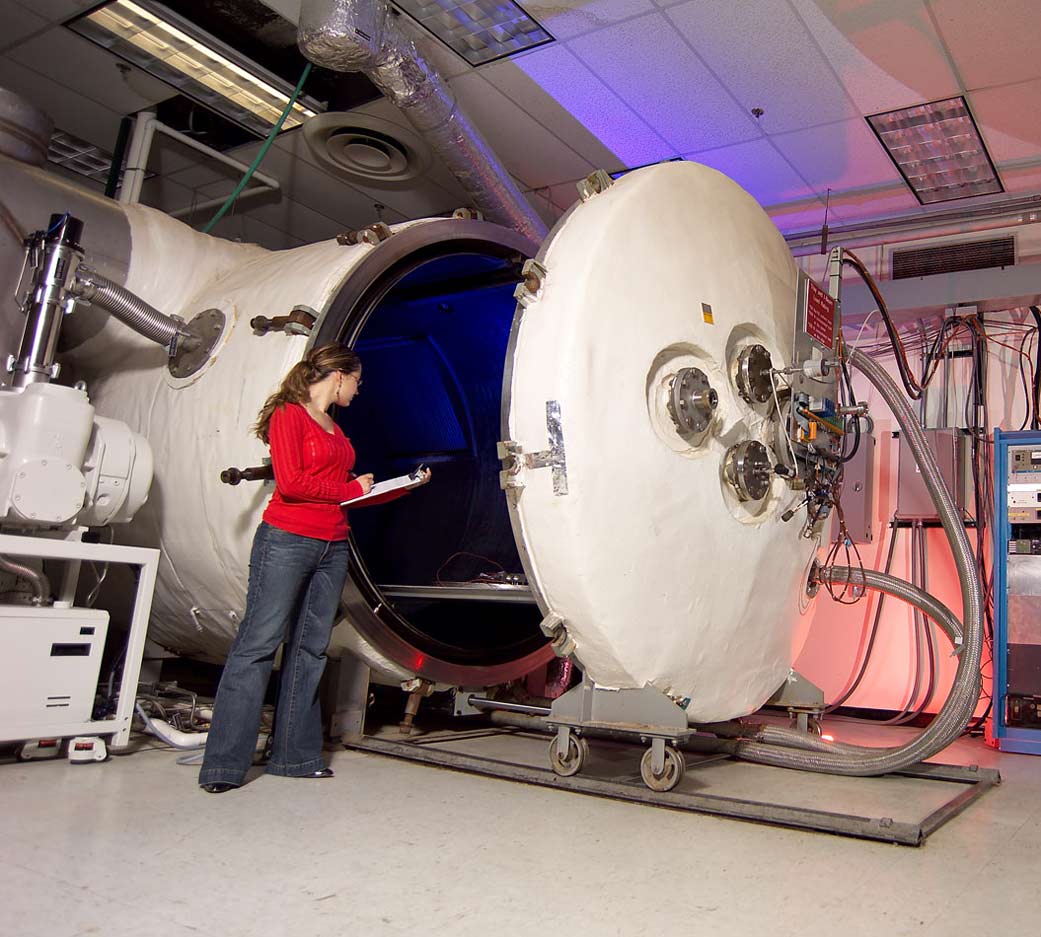

Spacecraft materials and components are tested by placed them in one of our test chambers and removing the air to simulate the vacuum of space. Our chambers are designed to be highly robust. Unique to our site is the ability to handle the testing of “dirty” materials with significant outgassing. We can expose test items to vacuum environments as low as 1.33 x 10 -5 Pa (1 x 10 -7 torr) and temperatures ranging from ambient to 149 °C (300 °F).

Vacuum Stability Testing

Vacuum stability testing is conducted to determine if a material will contaminate nearby sensitive equipment. Testing is conducted to determine the amount of volatile condensable materials that are released when exposed to vacuum per Standard Test Method for Total Mass Loss and Collected Volatile Condensable Materials from Outgassing in a Vacuum Environment (ASTM E595). Components can be similarly evaluated by Configurational Thermal Vacuum Stability (CTVS) and collected volatile condensable materials (CVCM) testing.

Environmental Conditioning

Our test systems are routinely used to help “clean” materials and hardware by extracting compounds via vacuum outgassing so that these compounds are not released in space where they may contaminate sensitive equipment.

Performance Evaluation

Test items are exposed to space vacuum conditions to determine if they are capable of performing the tasks for which they are designed.