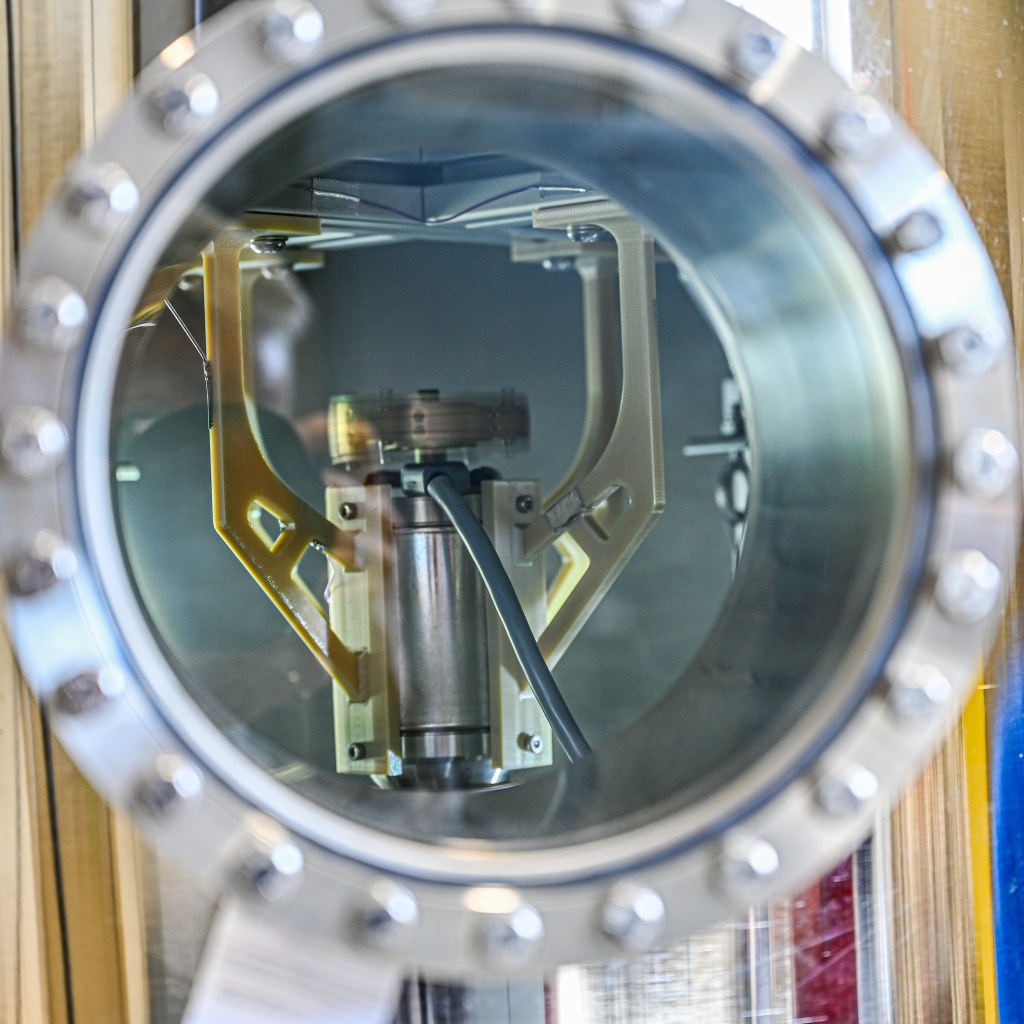

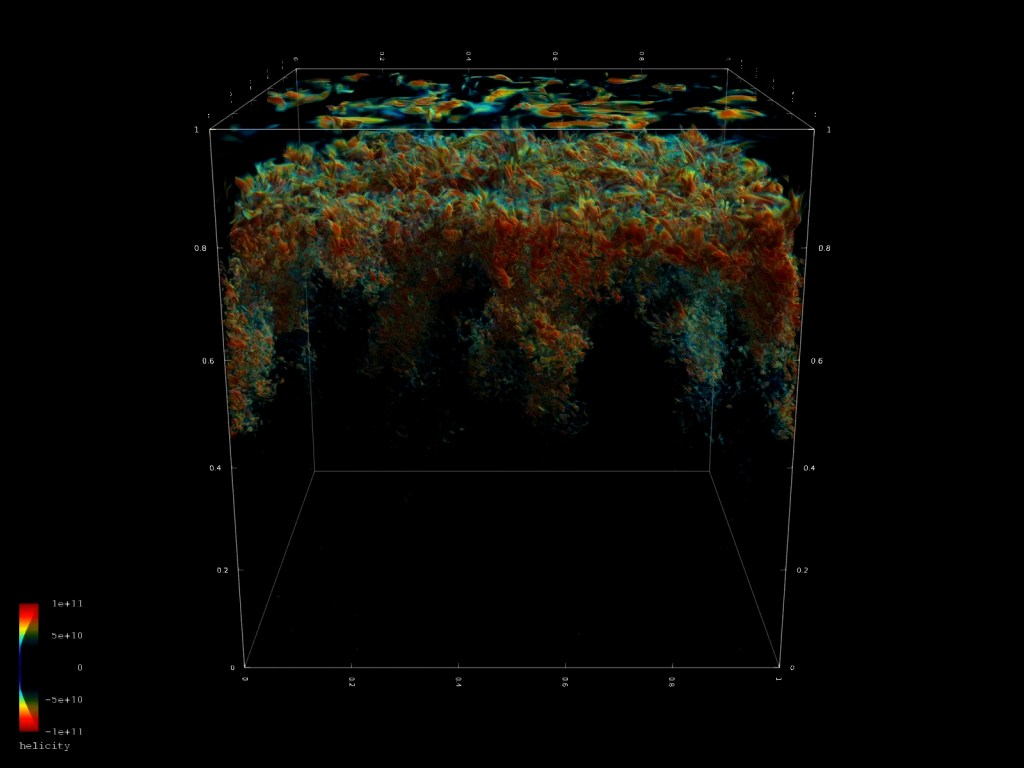

3D scanning is a no contact, laser-based technology used to generate highly accurate and detailed 3D CAD models of physical parts including those under testing conditions or in use. The information provided eliminates guesswork, reduces development time, and verifies design specifications, critical tolerances, and quality standards are being met.

Inspection and Failure Analysis

A 3D scan of an object can be compared to original CAD models to quickly gather accurate, high resolution data. Discrepancies between the scanned and original models immediately pinpoint issues such as wear, material issues and defects, warping, and twisting.

Reverse Engineering/Redesign

Existing or damaged parts can be scanned to create functional CAD models and drawings in support of legacy equipment or equipment with insufficient design documentation. Surface models can be used by our machining and fabrication personnel to create tool and die and CAD models can be modified for redesign purposes.