Michoud: Roles and Capabilities

As NASA enters a new era in space travel, NASA’s Michoud Assembly Facility in New Orleans is providing vital support to NASA’s exploration mission, and will play a key role in sending new voyages of discovery to destinations beyond Earth orbit — extending a human presence across the solar system.

A Leader, Past and Future

From the Apollo Program to the Space Shuttle era and now the Space Launch System, Michoud has long been a key asset in realizing NASA’s exploration missions. Drawing on the facility’s proven expertise and skills in the assembly and manufacture of large space systems and hardware, Michoud is continuing this legacy as NASA looks to the future of exploration and discovery.

Michoud’s laboratories are equipped with the latest materials, processing and production support for testing large structures, components and full-scale hardware. The facility also includes one of the world’s largest manufacturing plants, with 43 acres under one roof and a working port with deep-water access, enabling transportation of large space systems and hardware. In total, the site spans 829 acres, including ample green space – prime land for new office, manufacturing and test facilities.

The facility is large enough to serve multiple programs and projects — even expanding to include new, non-NASA tenants who increase the value and profile of Michoud, and add to the expertise and capabilities of the facility. Since the Space Shuttle, Michoud’s unique multi-tenant model helps to offset the production costs. These partnerships also could provide ample opportunities for new, high-value technical training in state-of-the-art manufacturing processes, further advancing the Michoud workforce’s expertise and skill base.

Michoud also is home to the National Center for Advanced Manufacturing, a partnership between NASA, the state of Louisiana, Louisiana State University and the University of New Orleans. The center provides advanced manufacturing technology for use in aerospace commercial markets. Through this partnership, new welding, fabrication and materials evaluation techniques developed by NASA and its partners will play a crucial role in development of NASA’s next-generation exploration and launch vehicles.

These capabilities, along with a highly skilled workforce, are a long-term benefit to development of NASA’s next-generation space transportation systems. In addition, the facility is large enough to serve multiple programs and projects supporting the agency’s exploration goals.

The Space Launch System and Orion

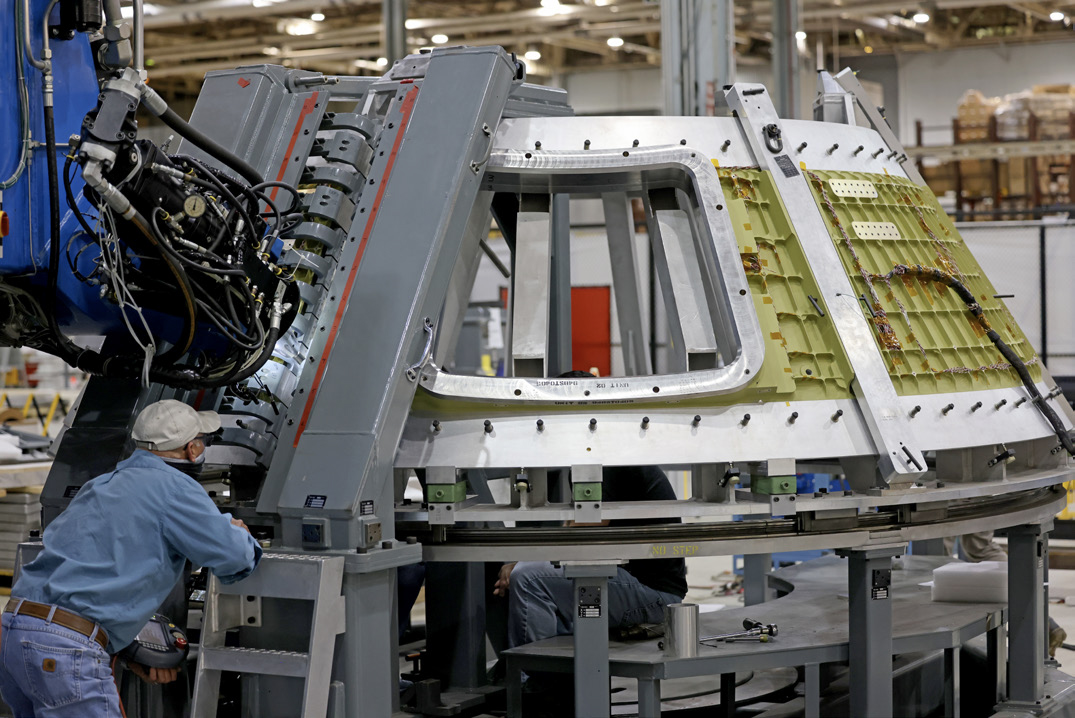

Today, the primary responsibility of Michoud is to support NASA’s flagship exploration programs.

Michoud is tasked with manufacturing and assembling the Space Launch System core stage, built by The Boeing Company. The SLS main propulsion system also will be assembled and integrated at Michoud, including the core stage’s proven RS-25 engines, built by Aerojet Rocketdyne of Sacramento, Calif.

The facility also is manufacturing large structures and composites for the Orion crew exploration vehicle, the spacecraft now being built by Lockheed Martin of Bethesda, Md., for NASA to carry a new generation of astronauts to destinations across the solar system.

These projects sustain and enhance Michoud’s role as a key player in carrying out NASA’s primary objective: continuing the world’s most robust space exploration program — one that will aid in advancing our nation’s scientific, economic and security interests.