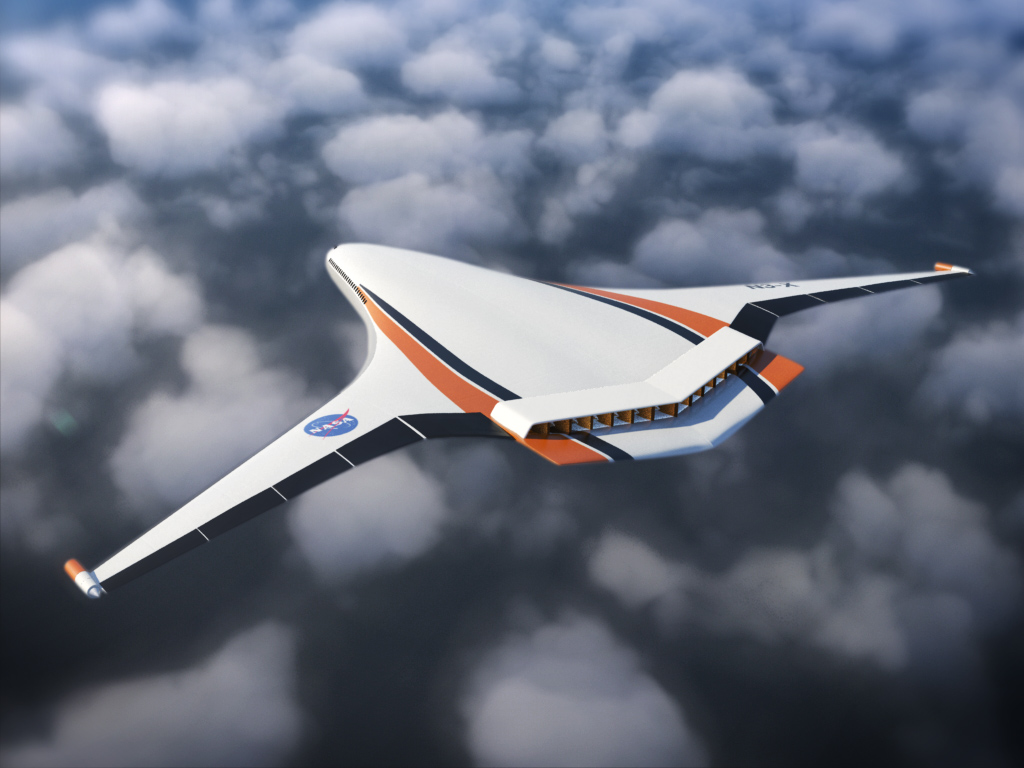

When the Space Launch System (SLS) lifts off from Earth with more power than any rocket NASA has ever built and soars toward the Moon for the Artemis I mission, it will be propelled by the knowledge, skill, and support of the people and programs at every NASA center across the country.

While Artemis is an agencywide effort, many of the people, programs, and facilities that built, tested, and readied the mega rocket and other key Artemis components for this next era of spaceflight are at Marshall Space Flight Center in Huntsville, Alabama. Marshall has not only contributed to Artemis I, but teams are already building rockets and working on other technology and hardware needed for future missons that will land the first woman and the first person of color on the surface of the Moon, part of establishing a long-term lunar presence.

“Artemis I will carry a lot of the expertise, effort, and pride of our Marshall team members,” Marshall Director Jody Singer said. “From manufacturing and testing the bones and brains of the Space Launch System rocket, to supporting it through this flight and beyond, we are so proud to contribute to this historic achievement in our nation’s space program. Go Artemis!”

Marshall is home to the Space Launch System Program Office, which leads the planning, design, development, testing, evaluation, production, and operation of the integrated launch vehicle. Marshall team members also developed and tested the flight software in-house and built key parts of the rocket in manufacturing facilities at Marshall and at Michoud Assembly Facility in New Orleans.

Marshall has a legacy of propelling NASA’s exploration through engineering, which is essential for a return to the Moon. Below are some of the many distinct facilities, tools, and hardware at Marshall that contributed to the Artemis I mission.

Facilities and Hardware

Marshall engineers have designed, developed, tested, and delivered SLS software that will tell the Artemis I rocket how to operate during its launch and ascent to orbit. The Systems Integration Lab/Systems Integration Test Facility allows engineers to fully simulate the integration of software and hardware systems prior to hardware manufacturing and test flight. Engineers also create and run end-to-end simulation environments that support the entire project life cycle. These unique capabilities ensure that software and hardware integrate seamlessly before vehicle manufacturing and assembly.

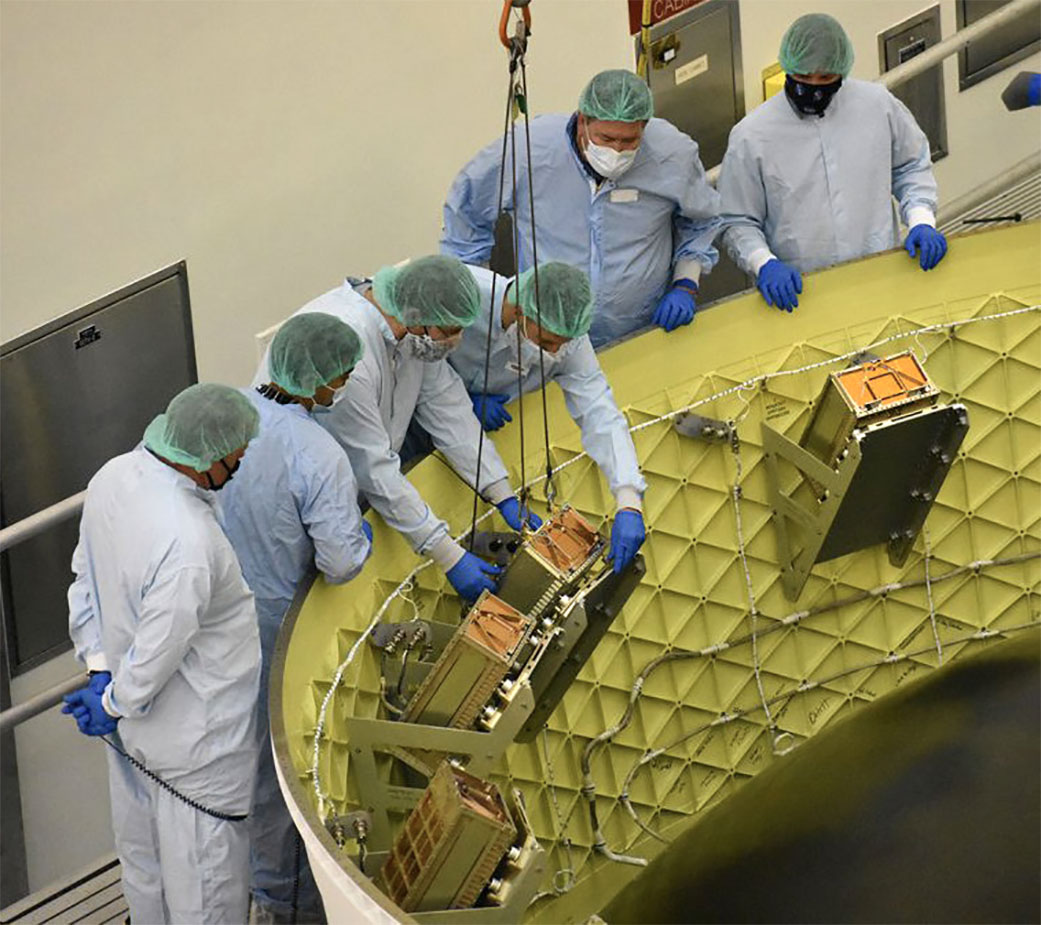

The launch vehicle stage adapter (LVSA) was built at Marshall’s Advanced Manufacturing Facility. The facility supports the center’s unique, cutting-edge tools and systems additive manufacturing, including laser welding and 3D printing. The cone-shaped LVSA was manufactured on a 30-foot welding tool – it is the largest piece of the rocket built at the facility. The LVSA provides structural support for launch, and also protects avionics and electrical devices from extreme vibration and acoustic conditions during launch and ascent.

The Orion stage adapter (OSA), also constructed at the Advanced Manufacturing Facility, will join Orion to the rocket’s interim cryogenic propulsion stage – a liquid oxygen/liquid hydrogen-based in-space stage that will give the spacecraft the push needed to go to deep space. The OSA contains a diaphragm that provides a barrier to prevent gases generated during launch, such as hydrogen, from entering Orion. The OSA will also carry small secondary payloads, called CubeSats, to deep space to perform their own science missions.

The Orion launch abort system, which will carry the crew to safety in the event of an anomaly during a future Artemis launch, is managed at Marshall.

The SLS Engineering Support Center (SESC), located in the Huntsville Operations & Support Center, allows engineers specializing in the engines, boosters, core stage, avionics, and upper stage to monitor the rocket’s propulsion and other systems during the countdown and flight. Leading up to and during launch, teams in the SESC analyze and monitor temperatures, pressures, flow rates, stresses and other types of telemetry from the rocket. They also produce flash reports for the Mission Management Team and report on and archive launch vehicle data for additional study in the weeks and months after launch. During Artemis launches, the SESC will support the Launch Control Center at Kennedy Space Center in Florida, and the Flight Operations Directorate team at the Mission Control Center at Johnson Space Center in Houston.

Test Stands

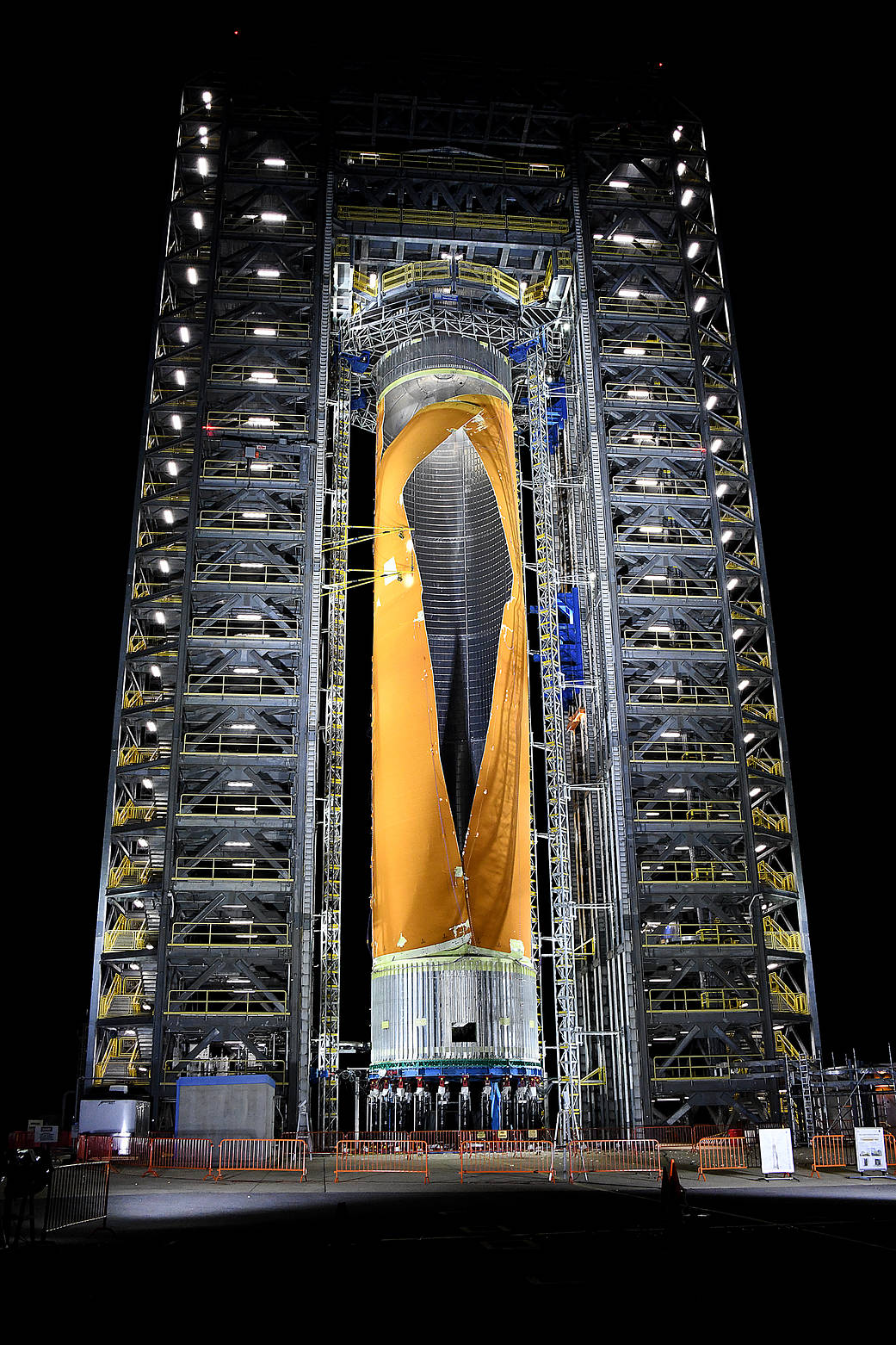

Building 4693 is a twin-tower open structure built to perform structural testing on a liquid hydrogen tank test article. Measuring 221 feet (67.3 meters) tall, the tower reuses the foundation of a former Apollo-era rocket test stand. For structural testing on the SLS liquid hydrogen tank structural test article, 38 hydraulic pistons were used to impart simulated flight loads on the tank, while more than 3,900 sensors measured temperature, deflection, strain, pressure, sound, and imagery.

Building 4698 is an L-shaped open tower structure built to test the liquid oxygen tank structural test article. Soaring 90 feet (27.4 meters) tall, the stand used 24 hydraulic pistons and more than 2,700 sensors to conduct 32 structural loads tests on the liquid oxygen tank structural test article.

Special test equipment consisting of two open-structure towers were built in Building 4619 to test core stage engine section and intertank structural test articles. The engine section was subjected to 49 tests and the intertank underwent 42 tests, both monitored by approximately 3,000 sensors.

Michoud Assembly Facility

For more than half a century, NASA’s Michoud Assembly Facility has been America’s rocket factory, the nation’s premiere site for manufacturing and assembly of large-scale space structures and systems. Michoud is NASA-owned and managed for the agency by Marshall.

Michoud’s state-of-the-art manufacturing and welding equipment – including a friction stir welding tool that is the largest of its kind in the world – was used to manufacture the SLS core stage. The hardware piece was then outfitted with avionics, thermal protection systems, propulsion systems and other internal hardware. Four RS-25 engines were then added to complete the assembly of the core stage, and the hardware continued on for testing.

Secondary Payloads

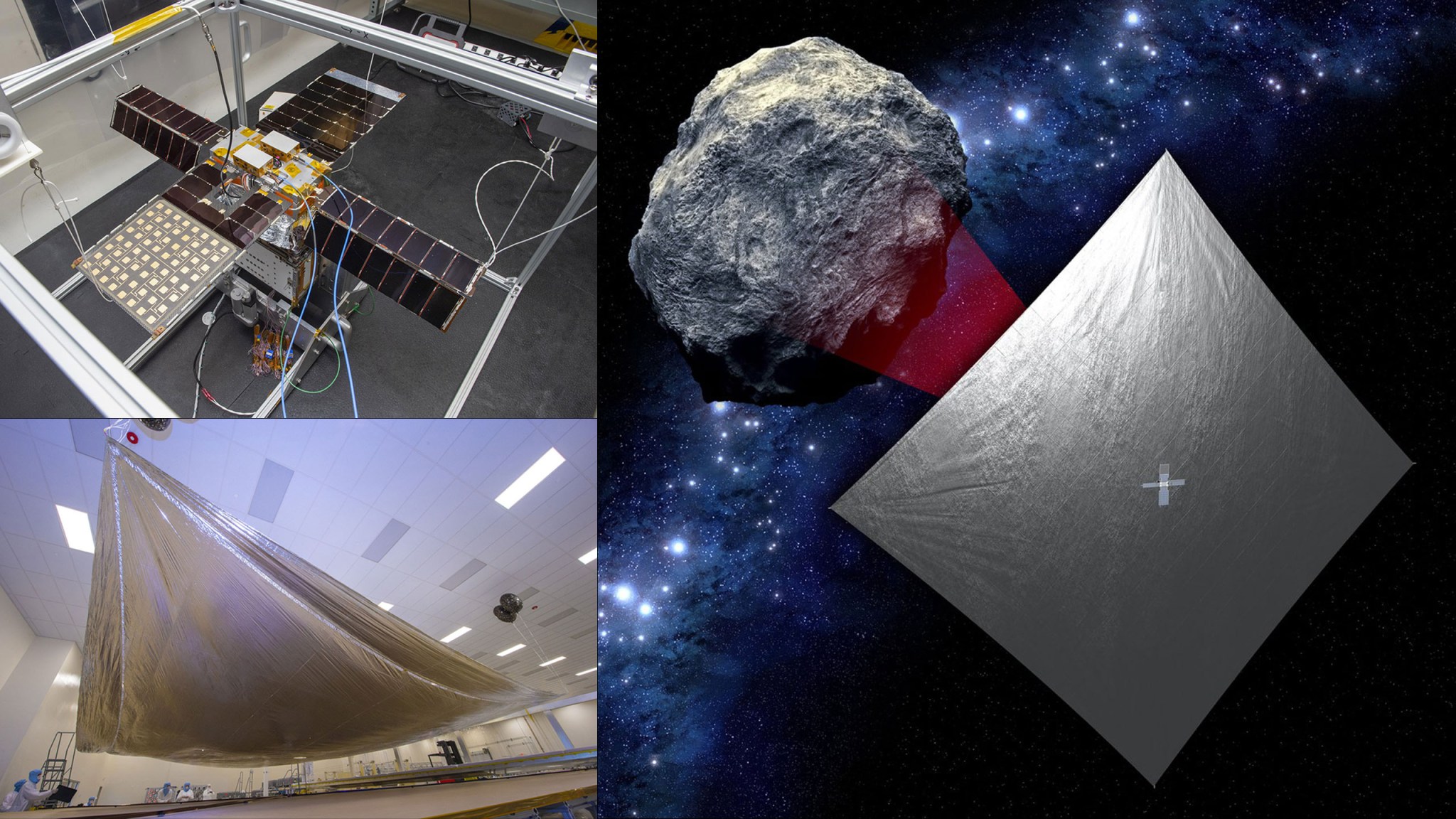

During the Artemis I flight, SLS will carry 10 CubeSats as secondary payloads with their own scientific or technology demonstration missions. These small sattelites are the size of a large shoebox and will ride to space inside the Orion stage adapter, which sits between the rocket’s interim cryogenic propulsion stage and Orion. Once in space and at the right time, each CubeSat will deploy to perform its own mission objectives. One of the Cubesats – NEA Scout – was designed and developed in part at Marshall; another is the product of a Marshall-managed technology competition.

NEA Scout CubeSat

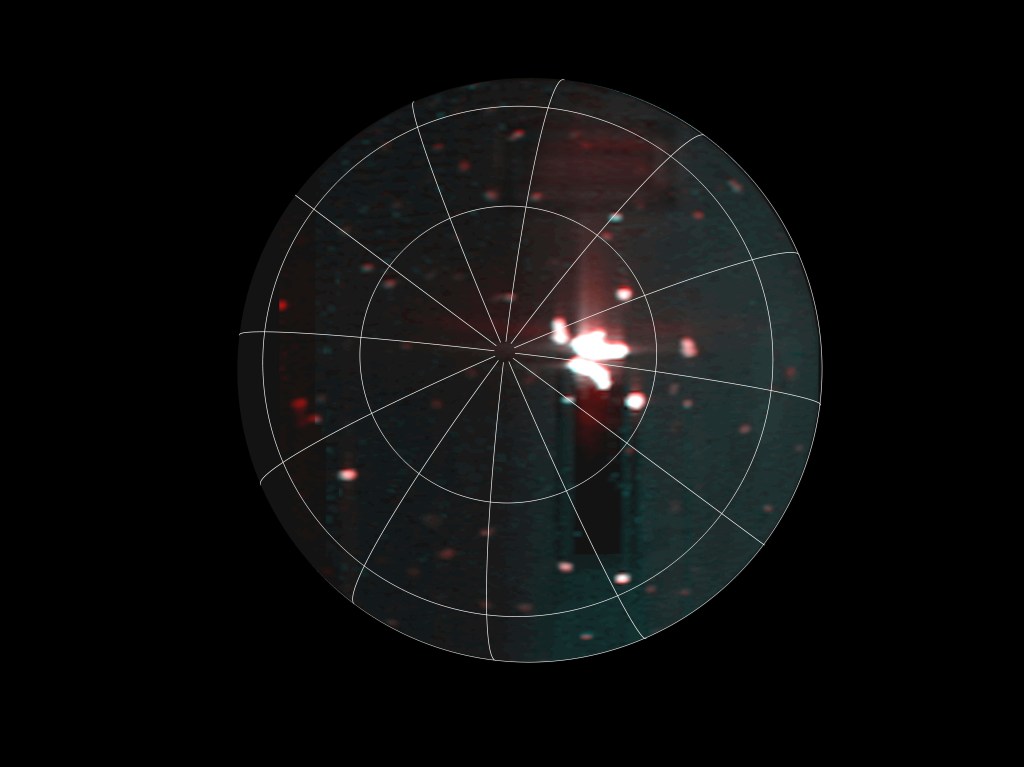

Near-Earth Asteroid Scout, or NEA Scout, was developed under NASA’s Advanced Exploration Systems program. The CubeSat was designed and developed by Marshall and NASA’s Jet Propulsion Laboratory in Southern California. Marshall’s Les Johnson is the principal investigator for NEA Scout, which will serve as a robotic reconnaissance mission to fly by and return data from an asteroid representative of near-Earth asteroids that may one day be human destinations.

Centennial Challenges’ Cube Quest Competition

NASA’s Centennial Challenges program, managed at Marshall, designs public competitions to stimulate research and technology solutions inside and outside of the traditional aerospace community. One of these competitions – Cube Quest – challenges teams to design, build, and deliver flight-qualified CubeSats capable of advanced operations near and beyond the Moon. Through a series of ground tournaments, Team Miles won a spot aboard Artemis I for their CubeSat to continue the competition in space. Their satellite will attempt to orbit the Moon and then journey to a deep space asteroid.

To learn more about the upcoming Artemis I mission, visit:

https://www.nasa.gov/artemis-1

To learn more about the Space Launch System rocket, visit: