Two NASA centers on opposite sides of the country are finding new ways to work together to support the agency’s mission to develop quiet supersonic technology, in spite of thousands of miles of distance and a global pandemic.

Using their available labs, Kennedy Space Center in Florida is building tools in collaboration with Armstrong Flight Research Center in California, which NASA will use in support of the X-59 Quiet SuperSonic Technology X-plane, or QueSST.

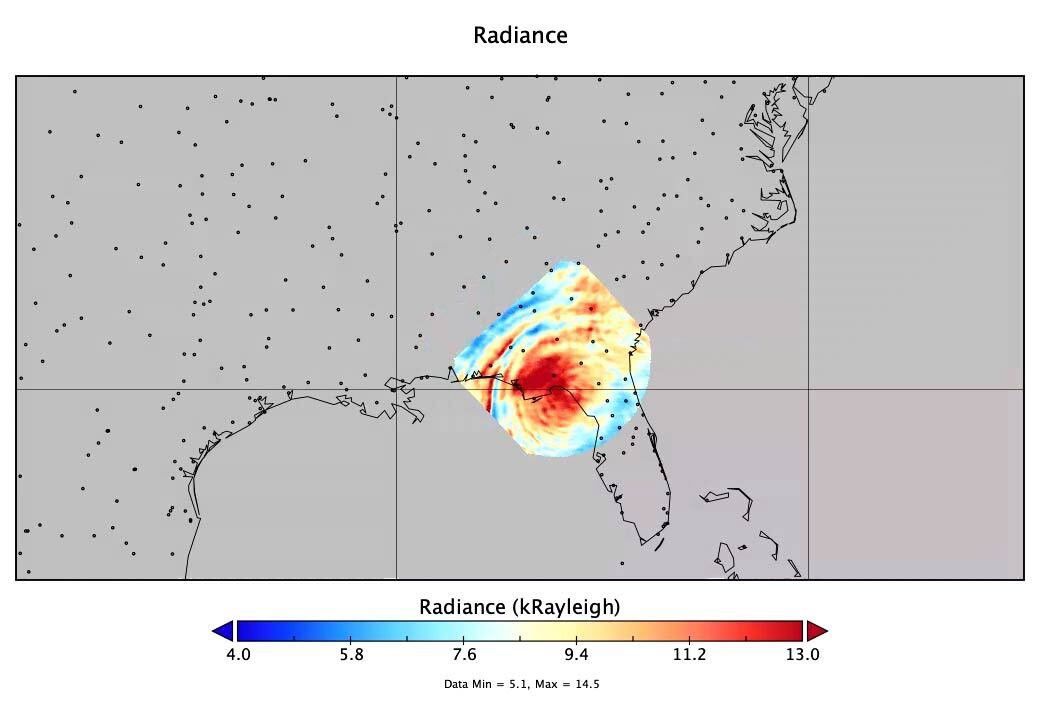

Flying at faster-than-sound speeds over communities around the U.S., the X-59 will demonstrate technology to reduce the loud sonic booms, typically heard below aircraft flying at supersonic speeds, to a quieter noise similar to a car door closing in the distance. The X-59 will demonstrate to regulators through collected data that quiet supersonic flight is possible.

However, before the X-59 begins community overflights, NASA researchers need to validate the X-plane’s acoustic signature through tests.

A project under NASA’s Aeronautics Research Mission Directorate called SCHAMROQ, which stands for Schlieren, Airborne Measurements, and Range Operations for QueSST, is preparing the tools and test techniques to execute these tests at Armstrong. When a reduced capacity to develop these tools materialized during the COVID-19 pandemic, Armstrong turned to Kennedy to provide a helping hand, and to help ensure the project’s progress.

“It’s neat working with a space center,” said Matthew Moholt, deputy project manager for SCHAMROQ. “Their willingness and eagerness to help out a sister center is welcomed and appreciated. When you have another center willing to help out and do critical work that’s critical to your schedule, that’s really significant.”

During supersonic flight, planes create shockwaves that merge together as they travel through the air to produce the sonic boom. Moholt says SCHAMROQ aims to build and test multiple tools to help researchers observe and validate these same shockwaves during quiet supersonic flight.

These tools include the Shock Sensing Probe, a device that will evaluate the characteristics of the X-59’s shockwaves while in flight, a schlieren photography technique to visualize the X-59’s shockwaves as they distort light through a camera, and a navigation software that will allow pilots to fly accurately during X-59 tests.

Moholt said all of this technology will be placed on a NASA F-15 research aircraft, which will take on the role of a chase plane, following the X-59 in the sky during flight tests to collect data.

“We have this big effort to instrument and put all the research systems into the F-15 that allows it to fly all of these technologies,” Moholt said. “As the pandemic hit, it was right in the peak of getting instrumentation wiring put through it so that all of our instrumentation systems could get put in, and our electronic fabrication shop was impacted by that.”

This SCHAMROQ technology needs to be tested to ensure it can withstand the demands of supersonic flight while onboard NASA’s F-15. Deputy instrumentation lead Matthew Waldersen said part of the testing process requires the usage of a network switch with cables – similar to an ethernet network, but for airplanes.

Waldersen explained that, to help ensure the project remained on schedule, Kennedy Space Center was contacted to build cables for the network switch.

“We reached out to their branch chief, and they said ‘yeah, we want to take this work on,’” Waldersen recalls. “‘We have the capacity, we’ve got the staff, we’ve got the ability to do it’, so this is fantastic.”

Jeff Crisafulli, branch chief of testing and design in Kennedy Space Center Engineering, said Kennedy identified onsite subcontractors capable of building these cables.

“These are highly skilled technicians, with 25-30 years of experience fabricating and designing, the NASA way,” Crisafulli said. “They’re considered part of the team.”

Crisafulli said each center at NASA has their own unique skillsets that they bring to the table, and that it is good to share knowledge. This collaboration between an aeronautics center like Armstrong and a space center like Kennedy reinforces one of NASA’s goals – working together for the benefit of the future.

“This is a unique opportunity to help out our buddies at Armstrong by providing this fabrication service,” Crisafulli said. “It goes back to the ‘One NASA’ idea – we are ‘One NASA’. This is a good example of pathfinding and opening up the door to some potential future work together.”