Our engineers refurbish, repair, and redesign fluid components such as check valves, relief valves, solenoid valves, and manual valves ensuring relief valves and other components are operating within manufacturer’s specifications and comply with the requirements of

- American National Standards Institute (ANSI)/NB 23,

- American Society of Mechanical Engineers (ASME) Code, Section VIII, Div. 1, and the

- National Board Inspection Code (NBIC).

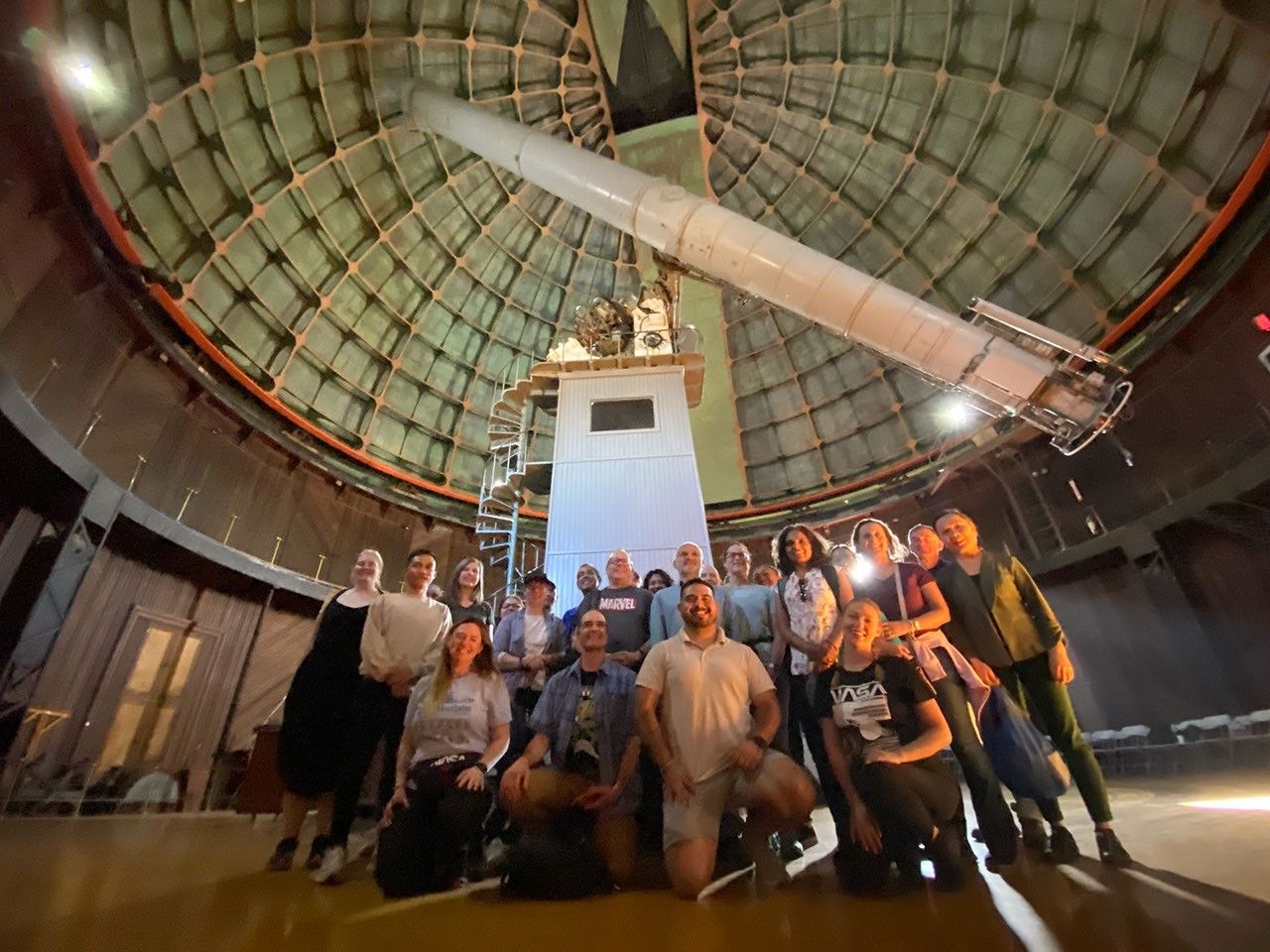

Facilities and Certifications

Component Services is an approved “VR” certified facility holding the National Board Inspection Code (NBIC) Certificate of Authorization and “VR” Symbol Stamp for the repair of pressure relief valves.

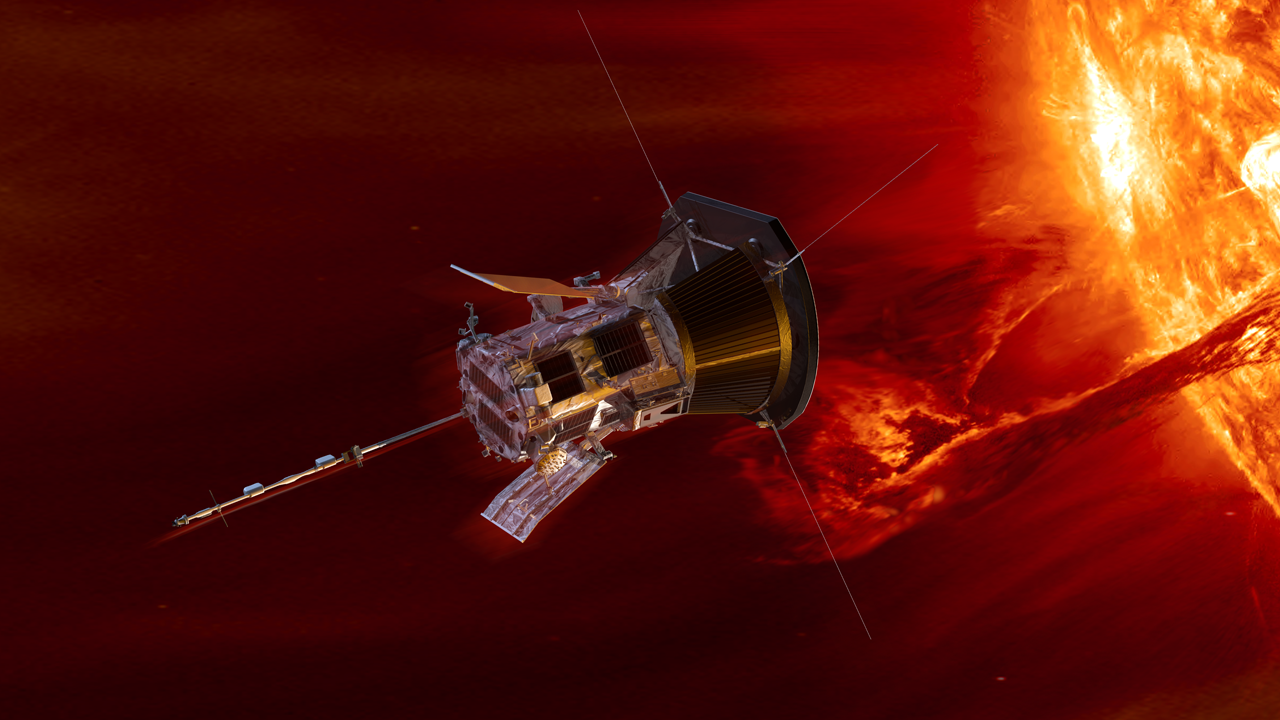

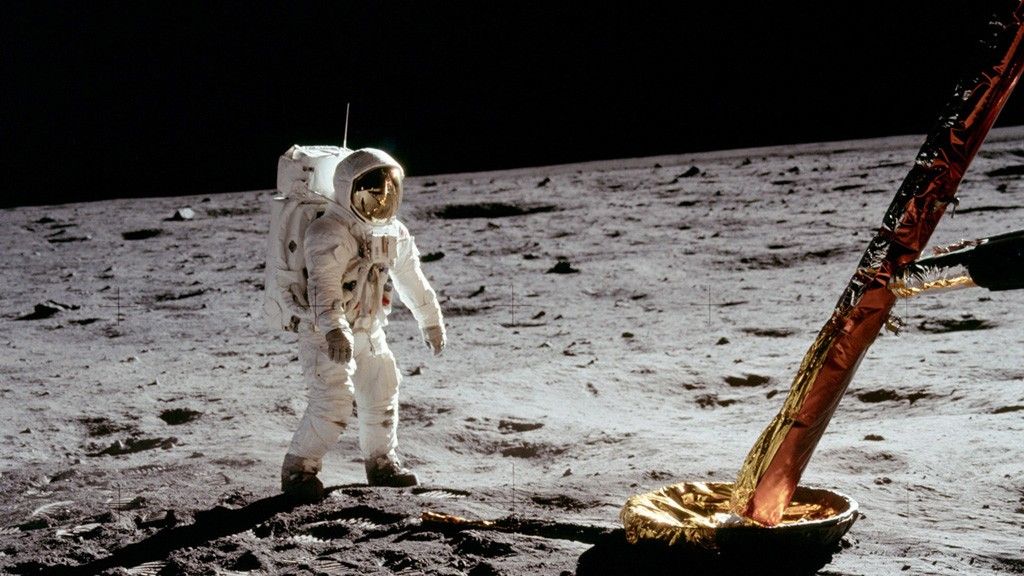

Our team is also certified to manufacture flight hardware by NASA and the International Space Station (ISS) Program.

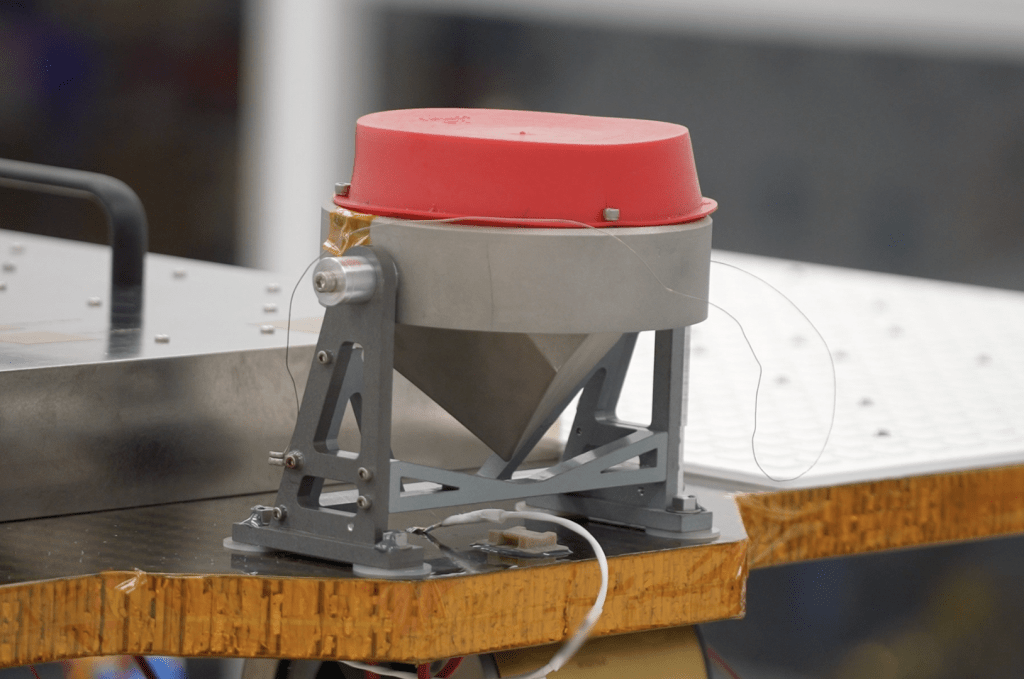

Repair and Refurbishment

Repair and refurbishment is a cost effective alternative to replacement and our highly skilled team disassembles, inspects, and precision cleans each item received. We ensure the parts being used for repair and replacement are from the original manufacturer, or from a vendor approved by the National Board verifying replacement parts meet original manufacturer specifications. Spares and replacements can be manufactured by our in-house NASA certified Machining and Fabrication workforce to replace parts that are no longer commercially available.

Modification

Equipment can be modified to work safely in your pressure system or in specific media such as oxidizer, oxygen service, fuels, and propellants. Guided by the knowledge gained from 40 years or research and testing by our Oxygen System and Propellants and Aerospace Fluids engineers, our team can modify equipment with recommended parts to operated safely and avoid costly mistakes created by using the wrong components.

Last Updated: Aug 6, 2017

Editor: Judy Corbett