In This Week’s Star

- › NASA Sets New Launch Window for Supersonic Vehicle Test

- › Center Director Scheuermann Visits Marshall Model Shop

- › MaterialsLab Improves How We Conduct Research On Earth and in Space

- › Marshall Brings Mars Exhibit to 2015 Destination Imagination

- › Magnetar Near Supermassive Black Hole Delivers Surprises

- › Marshall and Michoud Team Members Featured for Asian-American Pacific Islander Heritage Month

- › Marshall Celebrates Asian-Pacific Islander Heritage Month with Event, Guest Speaker

- › NASA Updates, Reissues ‘One-Stop Shop’ Software Catalog

- › Oklahoma State Students Present Concept Design of Deep-Space Habitats

- › NASA’s 3-D Printed Habitat Challenge Featured On ‘This Week @NASA’

NASA Sets New Launch Window for Supersonic Vehicle Test

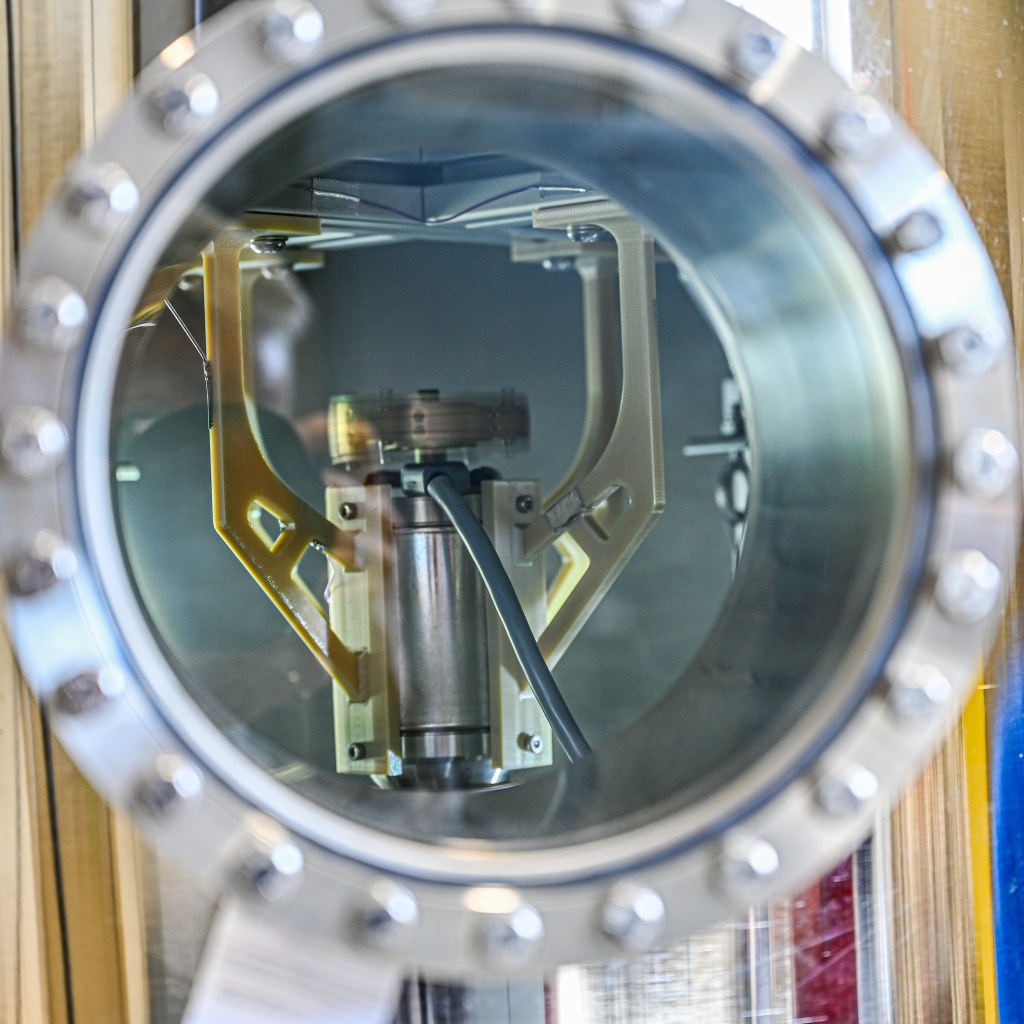

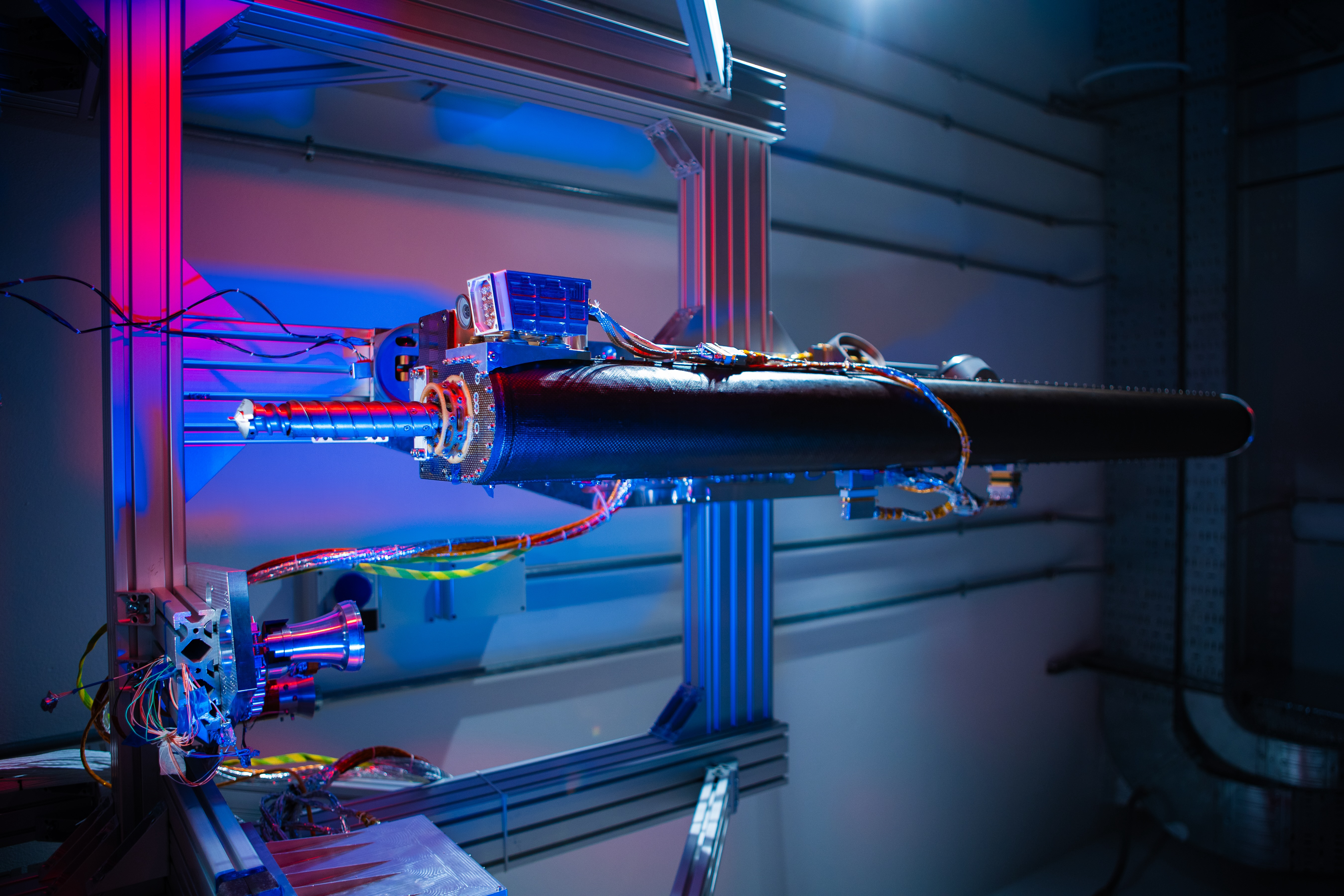

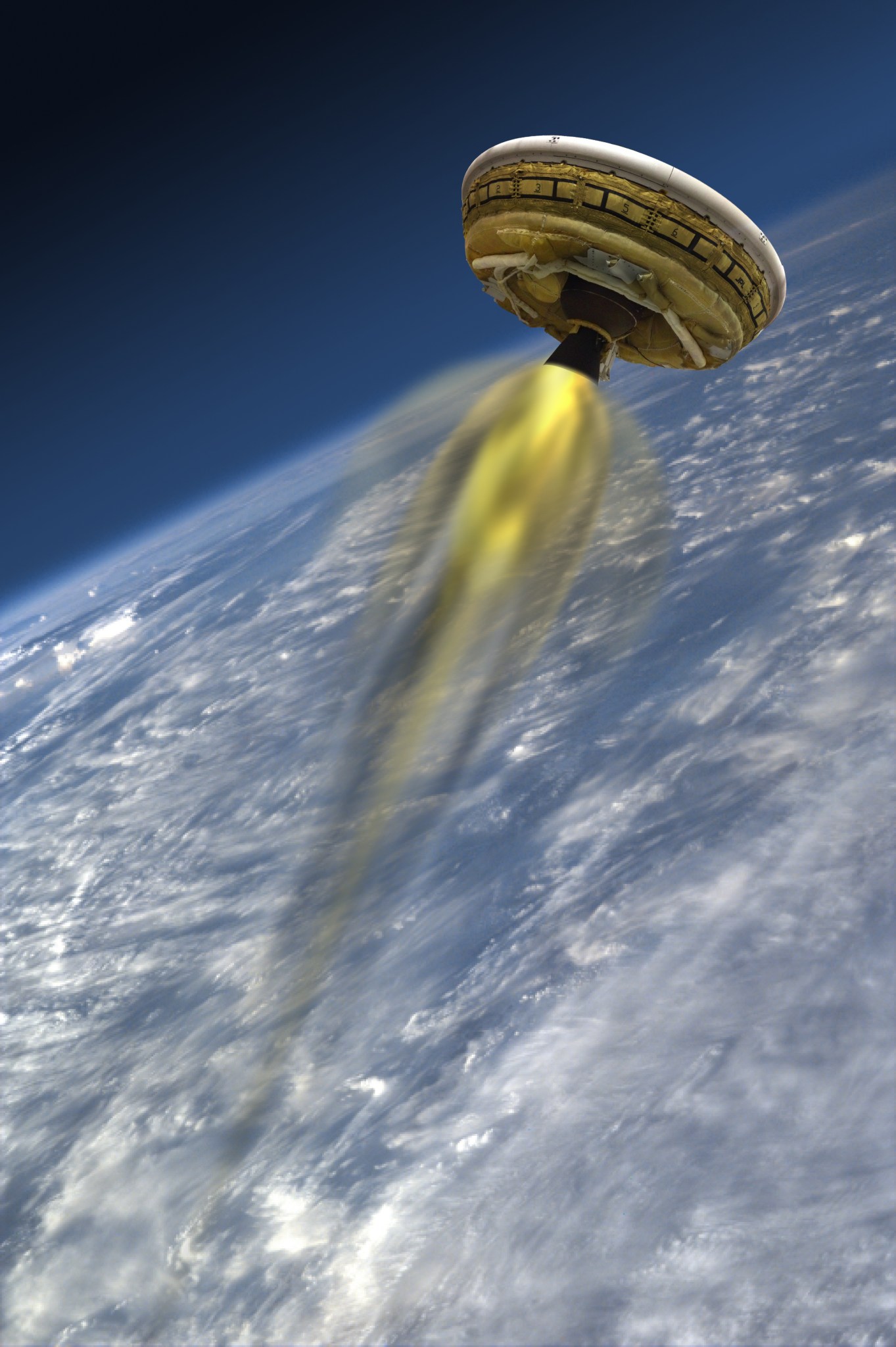

The second flight test of NASA’s Low-Density Supersonic Decelerator now will launch no earlier than 11:30 a.m. CDT June 2, from the U.S. Navy’s Pacific Missile Range Facility on Kauai, Hawaii. NASA Television coverage will begin at noon CDT.

To accommodate prevailing weather conditions, mission managers moved the launch window one hour earlier to increase the probability of LDSD launching on time.

NASA’s LDSD project is designed to investigate and test breakthrough technologies for landing future robotic and human Mars missions and safely returning large payloads to Earth. The test, performed over the Pacific Ocean, will simulate the supersonic entry and descent speeds at which the spacecraft would be traveling through the Martian atmosphere.

The test flight will be broadcast live on NASA TV and online on NASA’s Ustream channel.

The LDSD testing will be conducted through NASA’s Technology Demonstrations Missions program, based at NASA’s Marshall Space Flight Center, with the technology development work and testing led by NASA’s Jet Propulsion Laboratory. NASA’s Wallops Flight Facility is coordinating support with the Pacific Missile Range Facility and providing the balloon systems.

NASA’s LDSD program is part of the agency’s Space Technology Mission Directorate which innovates, develops, tests and flies hardware for NASA’s future missions. For more information about NASA’s investment in space technology, click here.

Center Director Scheuermann Visits Marshall Model Shop

On May 19, Patrick Scheuermann, third from right, director of NASA’s Marshall Space Flight Center, visited the Marshall Model Shop in Building 4631 to view 1:25 models of the crawler-transporter and mobile launcher. The models will be shipped to Kennedy Space Center later this month, where they will be paired with a model of the Space Launch System, also built at Marshall’s Model Shop. “New technology is great, but it’s no substitute for craftsmanship,” Scheuermann said during his visit to the shop, which is devoted to developing high-quality, high-fidelity models and exhibits for NASA and Marshall programs. Scheuermann was joined on his visit by Johnny Stephenson, far left, director of Marshall’s Office of Strategic Analysis & Communications. (NASA/MSFC/Emmett Given)

MaterialsLab Improves How We Conduct Research On Earth and in Space

By Bill Hubscher

When companies try to “build a better mousetrap,” the process can involve thousands of studies and tests on the kinds of advanced materials to use and effective designs. Those materials are the first building blocks of technological innovations in multiple industries including electronics, defense and energy. It can be a time-consuming but necessary operation, possibly taking up to 20 years from discovery to deployment, which means less time for people to use the device to solve a particular problem.

NASA and the National Institute of Standards and Technology are collaborating to help scientists and innovators build that new mousetrap by accelerating materials development and making new discoveries using data from the hundreds of investigations on the International Space Station.

“We want to conduct new investigations that fulfill a specific industry need or could lead to a new commercial application,” said John Vickers, the manager of the National Center for Advanced Manufacturing at the Marshall Space Flight Center. “If the automobile industry is having a problem with a specific material, we may be able to study that material on the station and get an answer that they couldn’t obtain through ground-based research. We are not only learning about the material, but also providing valuable data that immediately affects companies and consumers on Earth.”

An initiative between the two government agencies has created MaterialsLab – a new approach to materials science research that will provide unprecedented worldwide collaboration. Each space station investigation provides scientists with a better understanding of the physical and chemical properties of materials, allowing insight on how they develop and behave without gravity affecting the results. The MaterialsLab approach enhances the way researchers in government, industry and academia develop investigations and share information.

“We’re creating a new opportunity to develop materials experiments in space that makes it easier for scientists to conduct these investigations and share their research and data widely with the scientific community,” said Marshall Porterfield, NASA’s director of Space Life and Physical Sciences in the agency’s Human Exploration and Operations Mission Directorate at NASA Headquarters. “The Open Science concept allows multiple researchers around the world the ability to access data from station experiments and build on each other’s work.”

NASA and NIST recently signed a Memorandum of Understanding to foster collaboration among NASA’s microgravity materials science program, the NIST Material Measurement Laboratory and the multi-agency Materials Genome Initiative. The Materials Genome Initiative is a multi-agency initiative designed to create a new era of policy, resources and infrastructure that support U.S. institutions in the effort to discover, manufacture and deploy advanced materials twice as fast, at a fraction of the cost.

“Our partnership with NASA enables one of the key goals of the MaterialsLab concept, which is to transfer federally developed materials-related research and technology to industry,” said Laurie Locascio, director of the NIST Material Measurement Laboratory. “Both NASA and NIST want to accelerate the discovery, manufacture and deployment of advanced materials on the International Space Station and promote U.S. innovation and industrial competitiveness.”

MaterialsLab will share data from past and present space station experiments through NASA’s Physical Science Informatics system — a resource for processing and sorting data from physical science experiments performed aboard the space station. The goal is to promote an open access approach to scientific data analysis and potentially guide hundreds of new, station-based scientific investigations.

With MaterialsLab, NASA is changing the way scientists conduct research by adding a slight twist. Now, space station materials research will aim to solve engineering problems that not only relate to space travel, but also target a specific outcome or attack a materials problem identified by industry.

Through MaterialsLab, NASA is changing the way scientists share data and even their approach to proposing experiments. “It should be easy for investigators to access current data from experiments and use it to determine if there are gaps in knowledge that can be addressed with new investigations,” Porterfield said.

NASA leaders want to continue scientific experiments to learn more about the world and universe around us. They also want to change the way we conduct research by fostering a spirit of collaboration to share results from investigations on the orbiting laboratory as soon as possible.

Sharing findings from MaterialsLab in a comprehensive and open source, while building upon stored knowledge, has the potential to drive advances in materials science at a faster pace. You could see that new mousetrap on your store shelves sooner than you think.

Hubscher, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Marshall Brings Mars Exhibit to 2015 Destination Imagination

Thousands of students visited the NASA exhibit during the 2015 Destination Imagination, held in Knoxville, Tennessee, May 20-24. Its booth highlighted elements of NASA’s journey to Mars including the Space Launch System, the Orion heat shield and related educational games and activities. The event was part of Destination Imagination — a non-profit educational organization benefiting students. With an estimated 18,000 students in attendance, it was the place to be to learn how NASA’s Marshall Space Flight Center team members are helping put footsteps on Mars. (NASA/MSFC/Christopher Blair)

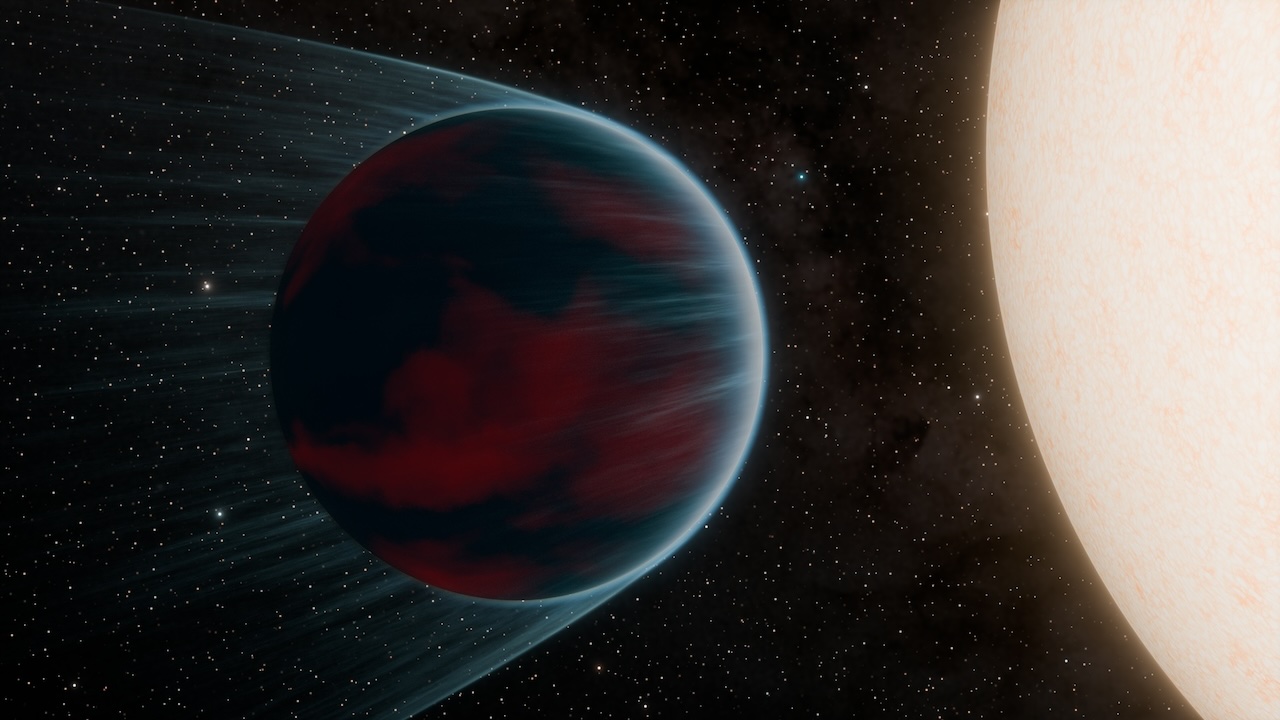

Magnetar Near Supermassive Black Hole Delivers Surprises

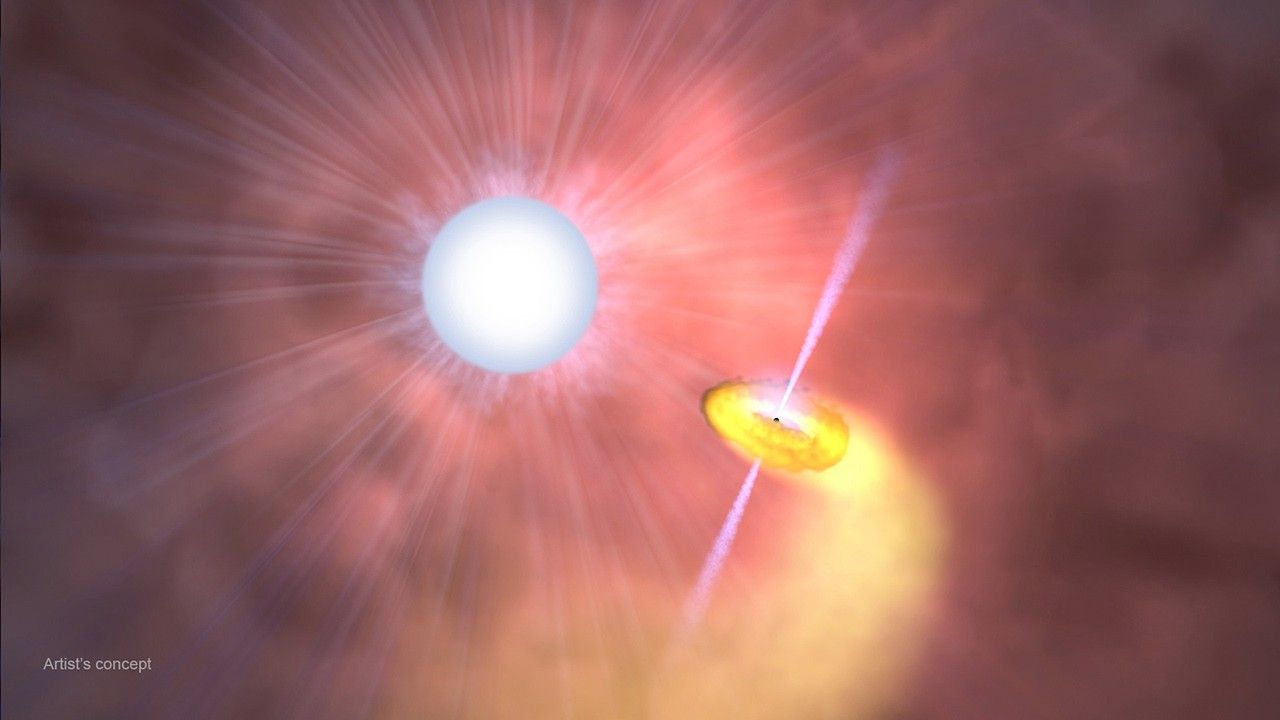

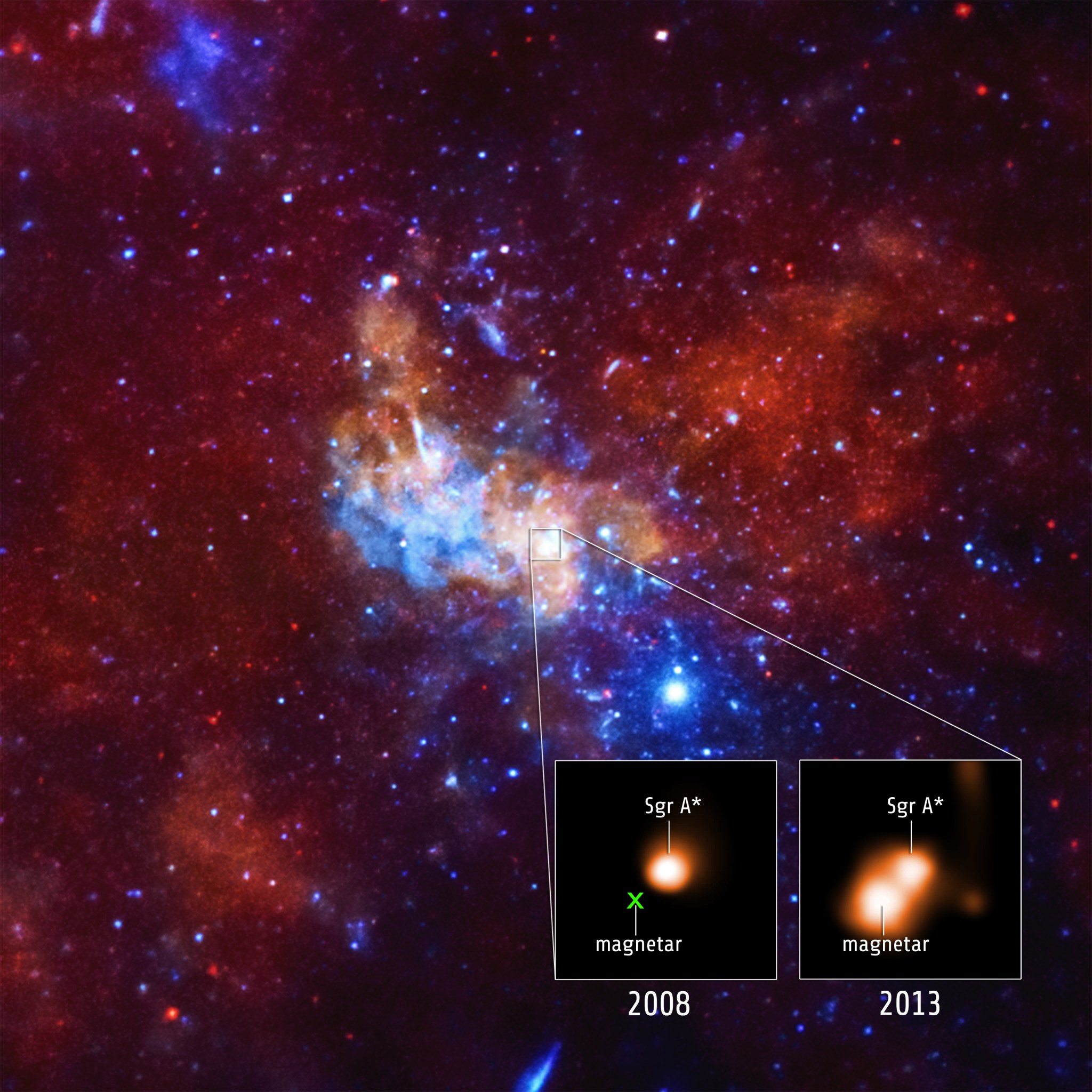

In 2013, astronomers announced they had discovered a magnetar exceptionally close to the supermassive black hole at the center of the Milky Way using a suite of space-borne telescopes including NASA’s Chandra X-ray Observatory.

Magnetars are dense, collapsed stars, called neutron stars, that possess enormously powerful magnetic fields. At a distance that could be as small as 0.3 light years, or about 2 trillion miles from the supermassive black hole in the center of our Milky Way galaxy, the magnetar is by far the closest neutron star to a supermassive black hole ever discovered and is likely in its gravitational grip.

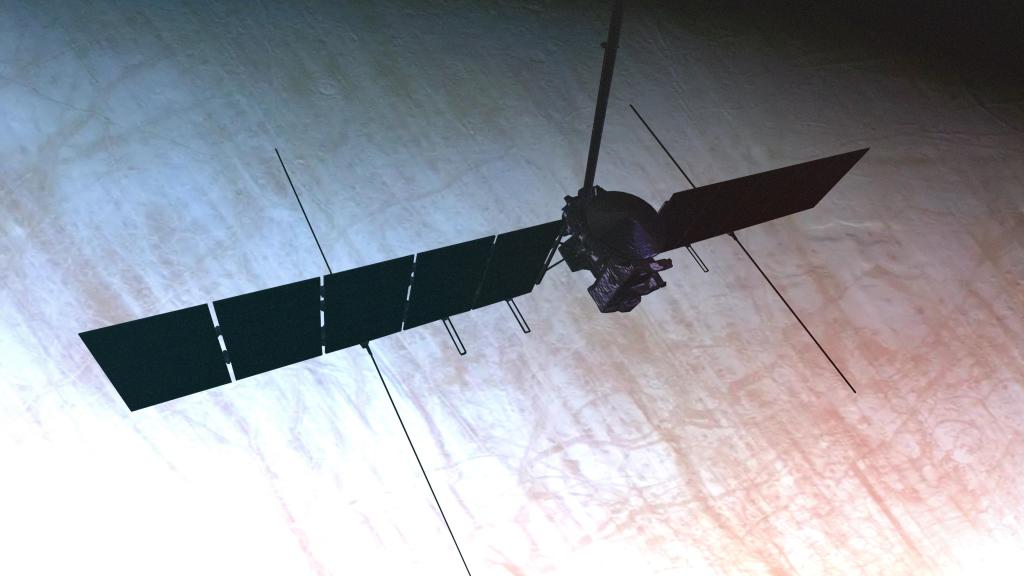

Since its discovery two years ago when it gave off a burst of X-rays, astronomers have been actively monitoring the magnetar, dubbed SGR 1745-2900, with Chandra and the European Space Agency’s XMM-Newton. The main image of the graphic shows the region around the Milky Way’s black hole in X-rays from Chandra (red, green and blue are the low-, medium- and high-energy X-rays, respectively). The inset contains Chandra’s close-up look at the area right around the black hole, showing a combined image obtained between 2005 and 2008, left, when the magnetar was not detected, during a quiescent period; and an observation in 2013, right, when it was caught as a bright point source during the X-ray outburst that led to its discovery.

A new study uses long-term monitoring observations to reveal that the amount of X-rays from SGR 1745-2900 is dropping more slowly than other previously observed magnetars, and its surface is hotter than expected.

The team first considered whether “starquakes” are able to explain this unusual behavior. When neutron stars, including magnetars, form, they can develop a tough crust on the outside of the condensed star. Occasionally, this outer crust will crack, similar to how Earth’s surface can fracture during an earthquake. Although starquakes can explain the change in brightness and cooling seen in many magnetars, the authors found that this mechanism by itself was unable to explain the slow drop in X-ray brightness and the hot crustal temperature. Fading in X-ray brightness and surface cooling occur too quickly in the starquake model.

The researchers suggest that bombardment of the surface of the magnetar by charged particles trapped in twisted bundles of magnetic fields above the surface may provide the additional heating of the magnetar’s surface, and account for the slow decline in X-rays. These twisted bundles of magnetic fields can be generated when the neutron star forms.

The researchers do not think that the magnetar’s unusual behavior is caused by its proximity to a supermassive black hole, as the distance is still too great for strong interactions via magnetic fields or gravity.

Astronomers will continue to study SGR 1745-2900 to glean more clues about what is happening with this magnetar as it orbits our galaxy’s supermassive black hole.

These results appear in Monthly Notices of the Royal Astronomical Society in a paper led by the doctoral student Francesco Coti Zelati (Universita’ dell’ Insubria, University of Amsterdam, INAF-OAB), within a large international collaboration.

NASA’s Marshall Space Flight Center manages the Chandra program for the agency’s Science Mission Directorate. The Smithsonian Astrophysical Observatory in Cambridge, Massachusetts, controls Chandra’s science and flight operations.

Marshall and Michoud Team Members Featured for Asian-American Pacific Islander Heritage Month

By Christopher Blair

In observance of NASA’s Asian-American Pacific Islander Heritage Month, three team members from NASA’s Marshall Space Flight Center and the Michoud Assembly Facility are sharing their stories: Rafiq Ahmed, a Marshall aerospace engineer; Gayleen Ijames, a Marshall ground systems engineer; and “Tim” Zhixian Li, a Michoud staff materials engineer.

Rafiq Ahmed – Marshall Aerospace Engineer

“Ever since a kid, I was always interested in aircraft and spacecraft,” said Rafiq Ahmed, an aerospace engineer in the Structural and Mechanical Design Branch, at NASA’s Marshall Space Flight Center. “I’m lucky because my dad was a materials science engineer and taught at Youngstown State University in Ohio. He provided a lot of exposure and encouragement to pursue science and engineering.”

His dad emigrated from India to Ohio in the 1950s, where Ahmed was born. As an only child and with no immediate family, his father found other ways to expose his only son to their native heritage.

“We were lucky Youngstown had a large Indian community. The local Indian heritage association sponsored dances and community events, so I would attend those. Plus, dad liked to invite students, faculty and community members to our house to grill shish kabobs and hang out.”

After graduating from the University of Pennsylvania in Philadelphia, Ahmed started working for NASA in 1987, where he now supports commercial crew designs for launch vehicles.

“This country has always been a melting pot of different people,” said Ahmed. “It’s great that people from different backgrounds come together to contribute to the U.S. space program and further our knowledge of the universe.”

His advice for anyone interested in pursuing science or engineering careers: “Get to know someone at NASA or our industry partners. One summer, I worked as a volunteer at the Langley Research Center as an undergraduate. It helped me to meet people and learn what it’s like to work at NASA.”

When he was in his 20s, Ahmed took his first of nine trips to India. “I travel to Calcutta every couple years — my last trip was in January 2014,” he said. “It’s amazing to see how technology has advanced. It’s a night-and-day difference from my first trip in 1986. The leap in just 30 years is astounding. What’s interesting is that India may even be more of a cell-phone nation than the United States, believe it or not.”

Giving back to his native culture, Ahmed took more than the typical hands-on approach by adopting two babies from India. His daughter is now 16 years old, and his son 15.

“What’s funny is that they are so totally Americanized, even more than I was,” said Ahmed. “Perhaps when they are older, they will become more interested in their heritage, like I am now.”

According to Ahmed, India has always placed a high value on learning English as a second language, and often, more as a first language. He said that many Indian families put their kids into English-speaking schools as early as possible.

“India has always emphasized the importance of education,” said Ahmed. “Most of my family has completed or are working toward a college degree. Education is not only important to my family, but in the Indian culture in general.

Gayleen Ijames – Marshall Ground System Engineer

Ijames works in the Payload Operations and Integrations Center supporting science experiments and payloads aboard the International Space Station. She graduated from the University of Alabama in Huntsville with a bachelor’s degree in industrial engineering and a master’s in systems engineering.

“Tim” Zhixian Li – Michoud Staff Materials Engineer

Li works for Lockheed Martin Information Systems and General Solutions, but is currently contracted to Boeing as a welding engineer on the Space Launch System. Having earned a doctorate degree from the Polytechnic School of Engineering at New York University, Li has spent 18 years working on research and development, technology demonstration article and production support on the friction stir welding process.

Blair, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

Marshall Celebrates Asian-Pacific Islander Heritage Month with Event, Guest Speaker

On May 26, NASA’s Marshall Space Flight Center marked Asian-Pacific Islander Heritage Month, featuring keynote speaker M. Farook Sait, above, former director of civil rights at the U.S. Department of Agriculture, Food Safety and Inspection Service and former special counsel to the assistant secretary for civil rights at the USDA. Sait spoke to Marshall team members about his experience living in the Southern United States as an immigrant in the 1960s. (NASA/MSFC/Charles Beason)

NASA Updates, Reissues ‘One-Stop Shop’ Software Catalog

By Rick Smith

NASA’s Office of the Chief Technologist has released the second edition of its popular NASA Software Catalog, a downloadable collection of software programs providing cutting-edge solutions for a wide array of industrial, academic, government and public applications.

The 172-page catalog, which includes more than 1,000 codes in 15 categories, is an updated expansion of the first edition, published in April 2014. It enables NASA projects, government agencies and other users to save money and time, using ready-made coding tools rather than buying or building their own.

“This product is the first and only offering of its kind in the federal government,” said Daniel Lockney, program executive for NASA’s Technology Transfer Program, which compiled and published the catalog for the agency. “It is setting the standard for how federal software assets should be shared broadly with the public.”

This year’s catalog has several new features, including a guide to NASA’s most-requested software tools and information about which tools are being used to build NASA’s next heavy-lift vehicle, the Space Launch System. Technologies found in the catalog — and in the regularly updated, searchable online version — range from project management systems, data handling and design tools to sophisticated solutions for aeronautics, life support functions, structural analysis and autonomous and robotic systems.

Some restrictions apply. Certain codes are limited to government users, while many others are available to any U.S. citizen. Each entry is clearly marked to identify availability. Contact information also is provided for NASA Software Release Authority representatives at relevant NASA centers, who can answer questions and assist with software tools requests.

Catalog origins

The catalog originally stemmed from a White House memorandum in October 2011, in which President Barack Obama called on federal agencies to find new ways to increase the efficiency and output of their technology transfer activities. In response, NASA developed a five-year plan that sought to locate, collect and make accessible all agency software.

The software catalog was the result. It makes the best of NASA’s software available to industry, and saves government projects the costs associated with writing their own codes. In the hands of NASA personnel, these tools maintain regular operation of the complex instruments on the International Space Station, Hubble Space Telescope and Mars rovers; enable efficient and safe launch operations; and help design new space vehicles. In industry hands, they can help create jobs, generate revenue and even save lives.

As the emerging commercial space industry takes flight, NASA software is providing strategic new benefits to both fledgling companies and longtime agency partners. NASA provides safety protocols and checkout tools, guidance and navigation codes and even the advanced design tools needed for building state-of-the-art spacecraft. Its software has been used by hundreds of non-aerospace companies, adapted for every conceivable operation — from managing complex shipping operations to designing rollercoasters, and from non-invasive tracking of endangered animal species to providing pattern-matching algorithms underpinning online dating sites.

User growth

Since the catalog debuted in 2014, NASA has seen a dramatic increase in code sharing across government projects, Lockney said — substantially reducing costs to U.S. taxpayers.

“Software is an increasingly significant portion of our technology portfolio,” he said. “We’re trying to make it as simple as possible for users to benefit from these valuable tools.”

The public response was even more overwhelming, with more than 100,000 downloads of the catalog and millions of website visitors to date. This surge has spurred NASA to develop ways to better serve its growing stakeholder community — updating software release procedures, automating processes and building the infrastructure necessary to collect and maintain its software assets.

The next step, Lockney said, is to build a software repository that will further accelerate the speed and efficiency with which users can access NASA codes. The agency also will simplify software use agreements and will implement a “click-wrap” agreement to more easily access a greater variety of available tools. These new features are expected to be in place by September 2015.

Smith, an ASRC Federal/Analytical Services employee, supports the Office of Strategic Analysis & Communications.

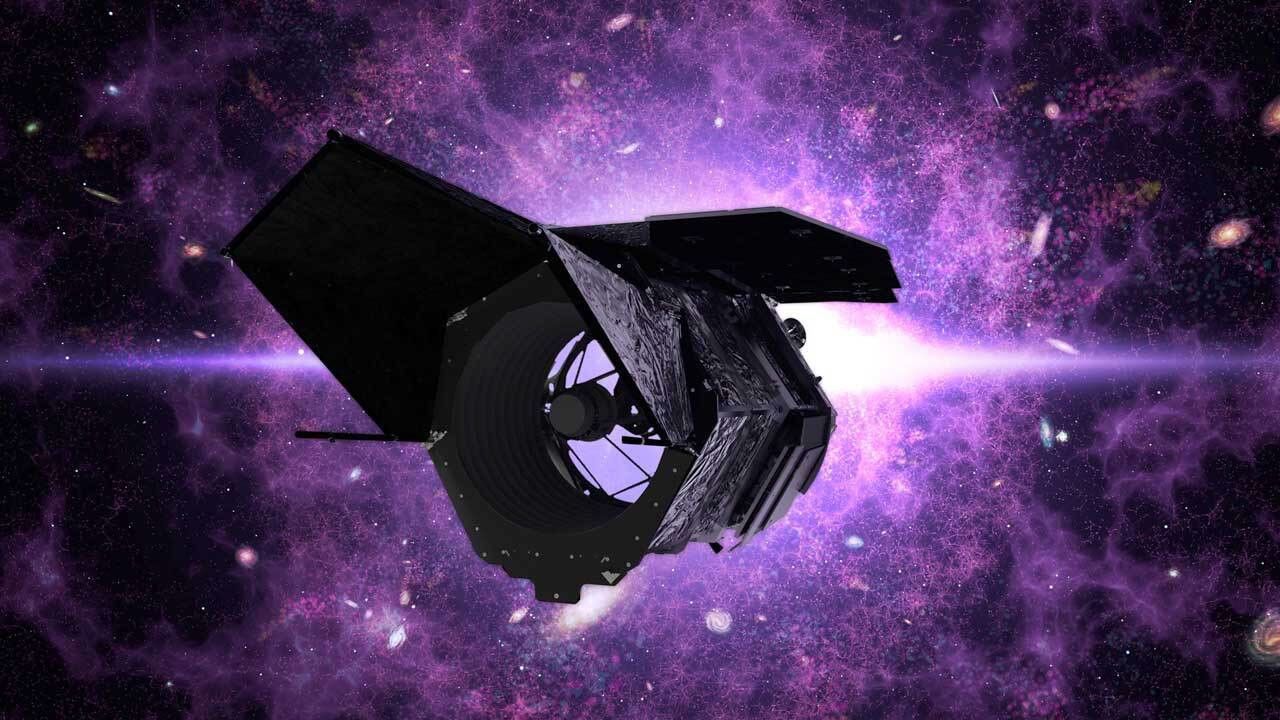

Oklahoma State Students Present Concept Design of Deep-Space Habitats

NASA’s Marshall Space Flight Center offered students from Oklahoma State University’s Virtual Engineering for Space Systems class an opportunity to gain some out-of-this-world, problem-solving skills in designing workspaces for future deep-space habitats.

The students were provided an Advanced Concepts Office space habitat concept design as a baseline and were tasked to develop workspaces for deep-space habitats. The baseline was designed for a 500-day mission that includes four astronauts. Under the direction of Marshall engineers, four teams of students developed detailed designs for several habitat sub-systems.

The teams focused on four unique workspaces: waste and hygiene compartment, galley/wardroom and sleeping quarters, workstations and modular stowage system, and fitness areas and equipment.

The students communicated regularly with Marshall engineers during the semester through teleconferences and a website created by the students. Once they completed the virtual System Readiness and Preliminary Design Reviews, they traveled to Marshall to present their designs in the Critical Design Review.

“This opportunity allowed these engineering students the opportunity to apply their classroom knowledge to a problem they may encounter in their place of employment,” said David Reynolds of the Systems Analysis Branch. “They worked together as a team with regular instruction from our group during the gated reviews and were able to present their CDR results at Marshall last month.”

In addition to the successful CDR presentation, the students also provided the Marshall engineers with a final report and a CAD model of their integrated team design.

The Systems Analysis Branch is currently constructing a full-scale concept demonstrator of the habitat and performing layout assessments and habitability studies necessary for developing the design requirements that would ultimately be used for the flight design.

Marshall has a rich heritage performing the up-front conceptual designs for many successful space missions, including the Hubble Space Telescope, the Chandra X-Ray Observatory, and the International Space Station. The Oklahoma State collaboration, along with other academia, industry and government agencies — partnering with NASA — will aid in the development and design of future deep-space habitats.

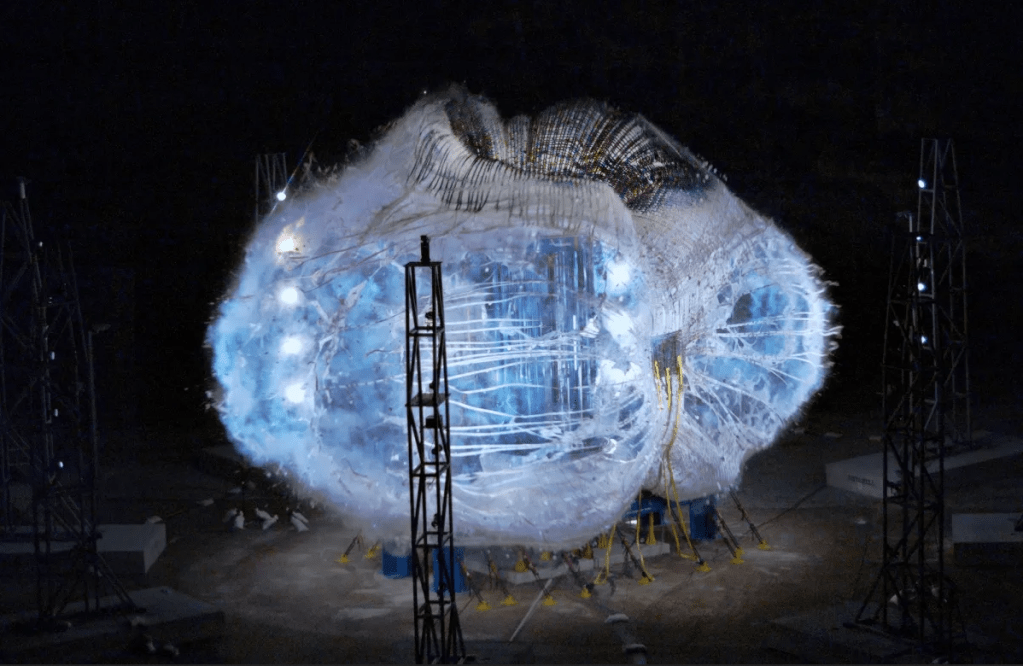

NASA’s 3-D Printed Habitat Challenge Featured On ‘This Week @NASA’

A new 3-D printed design challenge — part of NASA’s Centennial Challenges — was featured in the latest edition of “This Week @NASA,” a weekly video program broadcast nationwide on NASA-TV and posted online.

NASA and the National Additive Manufacturing Innovation Institute, known as America Makes, have announced a new $2.25 million competition to design and build a 3-D printed habitat for possible use on deep space exploration missions, including the agency’s journey to Mars. This competition is part of NASA’s Centennial Challenges, managed at NASA’s Marshall Space Flight Center, and is designed to advance the additive construction technology needed to create sustainable housing solutions for Earth and beyond. The first phase of the competition runs through Sept. 27. The top 30 submissions will be judged and a prize purse of $50,000 will be awarded at the 2015 World Maker Faire in New York.

NASA Centennial Challenges were initiated in 2005 to directly engage the public in the process of advanced technology development. The program offers incentive prizes to generate revolutionary solutions to problems of interest to NASA and the nation.

View this and previous episodes at “This Week @NASA” or at https://www.youtube.com/user/NASAtelevision.