Make it work. Make it count. Make a difference. For NASA Langley inventors, these three imperatives have guided their efforts over years, if not decades, conducting research that can dramatically benefit the daily lives of fellow citizens. Put simply, Langley innovation isn’t just reflected in designs for rockets, spacecraft and airplanes.

Take the case of a plastic-like material discovered more than 20 years ago by Langley’s Robert Bryant. Bryant was studying experimental materials for next-generation supersonic airplanes and lightweight rocket bodies, work that led to creation of Langley Research Center’s Soluble Imide, or LaRC-SI, a “thermoplastic” resistant to chemicals and capable of withstanding extreme hot and cold. The kicker: it was also biologically inert, a property that led medical equipment manufacturer Medtronic to incorporate the material as wires to control cardiac pacemakers.

Since LaRC-SI received Food and Drug Administration approval in 2010, more than 660,000 of the wires have been sold. In 2016, LaRC-SI was inducted into the Space Foundation’s Space Technology Hall of Fame. Medtronic continues to investigate the material’s usefulness in other medical devices.

Another matter of the heart involved a Langley research team’s development of sensors originally intended to measure airflow over airplane wings. Repurposed, the sensors were deployed to create a portable, non-invasive, easy-to-use fetal heart monitor: a wide, soft belt that at-home expectant moms could strap over their abdomens, tune a computerized control device to hear the fetal heartbeat, and send the signal directly to a doctor’s office via the internet.

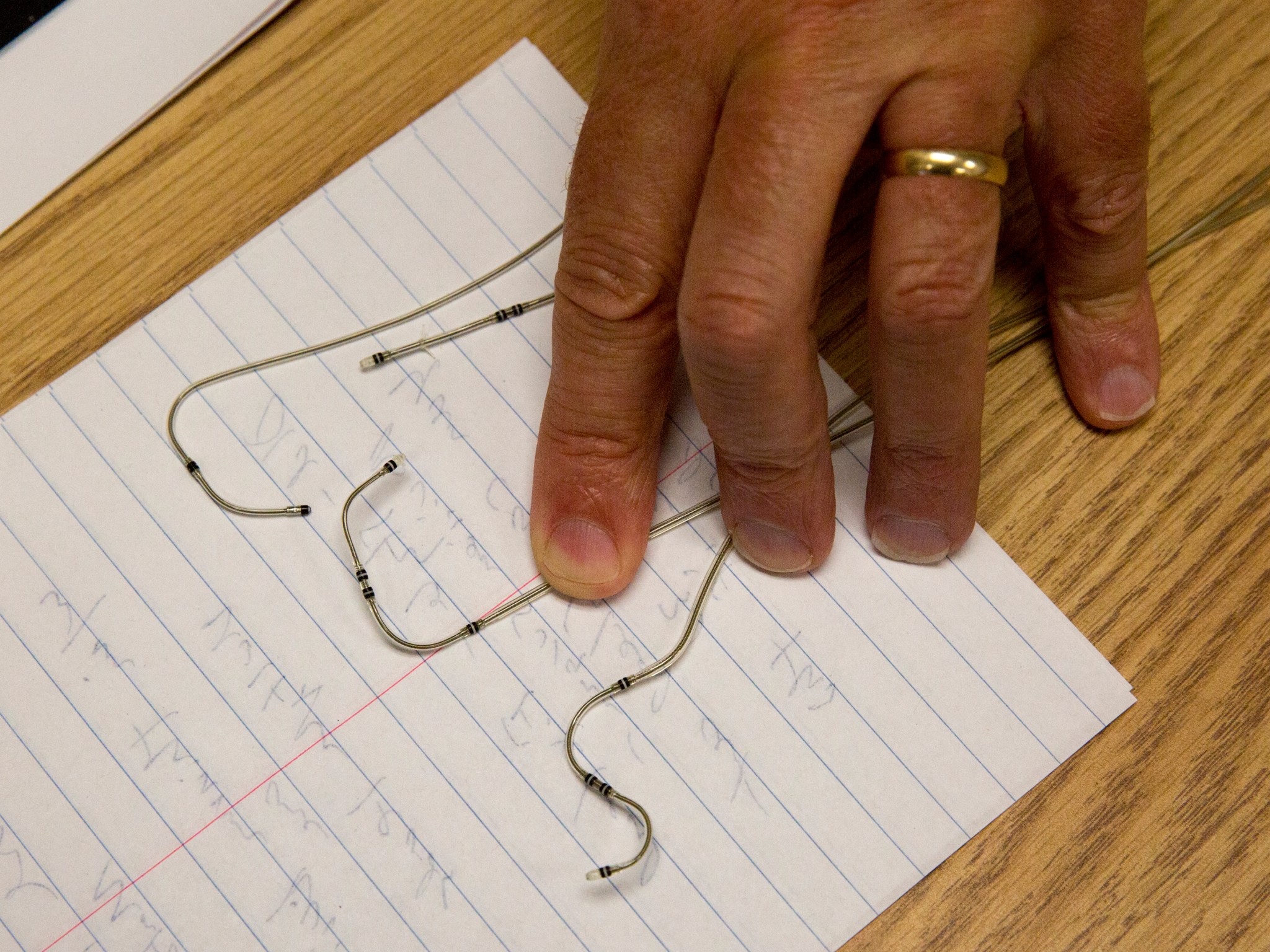

An entirely new type of sensor – known as SansEC or “without electrical connection” – was originally developed by the late NASA Langley researcher Stanley Woodard. The small devices can simultaneously measure different physical phenomena — temperatures and fluid levels, for example — and functions even when badly damaged. An antenna remotely accesses the sensor to collect the resultant measurements. Woodard initially imagined using the sensor on space systems, like inflatable habitats or specialty aircraft that could navigate the atmospheres of distant planets.

More down-to-Earth potential SansEC applications include monitoring of ice and snow accumulation on sidewalks, driveways and parking lots, or incorporation into security equipment. SansEC sensors are even tiny enough for bandages that would monitor wounds. And a company in Ohio is developing SansEC sensors for use in other health-related products to detect moisture, temperature and movement.

Invention on the Road Langley innovation literally took to the road in the early 1960s with an extensive research program that led to grooves cut into airport runways around the world. The technique was designed to curb skid-causing hydroplaning, a condition occurring during rainstorms when tires rolling or sliding along a soaked pavement are lifted away from the surface by water pressure.

Grooves cut transversely across runways solved the problem for aircraft, channeling excess water and enabling planes to brake with minimal hydroplaning. By 1967, grooving had been introduced to most U.S. airports, eventually followed by adoption on at least a portion of main highways across the country. Skidding was reduced, stopping distance decreased, and vehicles could more easily corner on curves. The process has since been extended to animal holding pens, steps, parking lots and other potentially slippery surfaces.

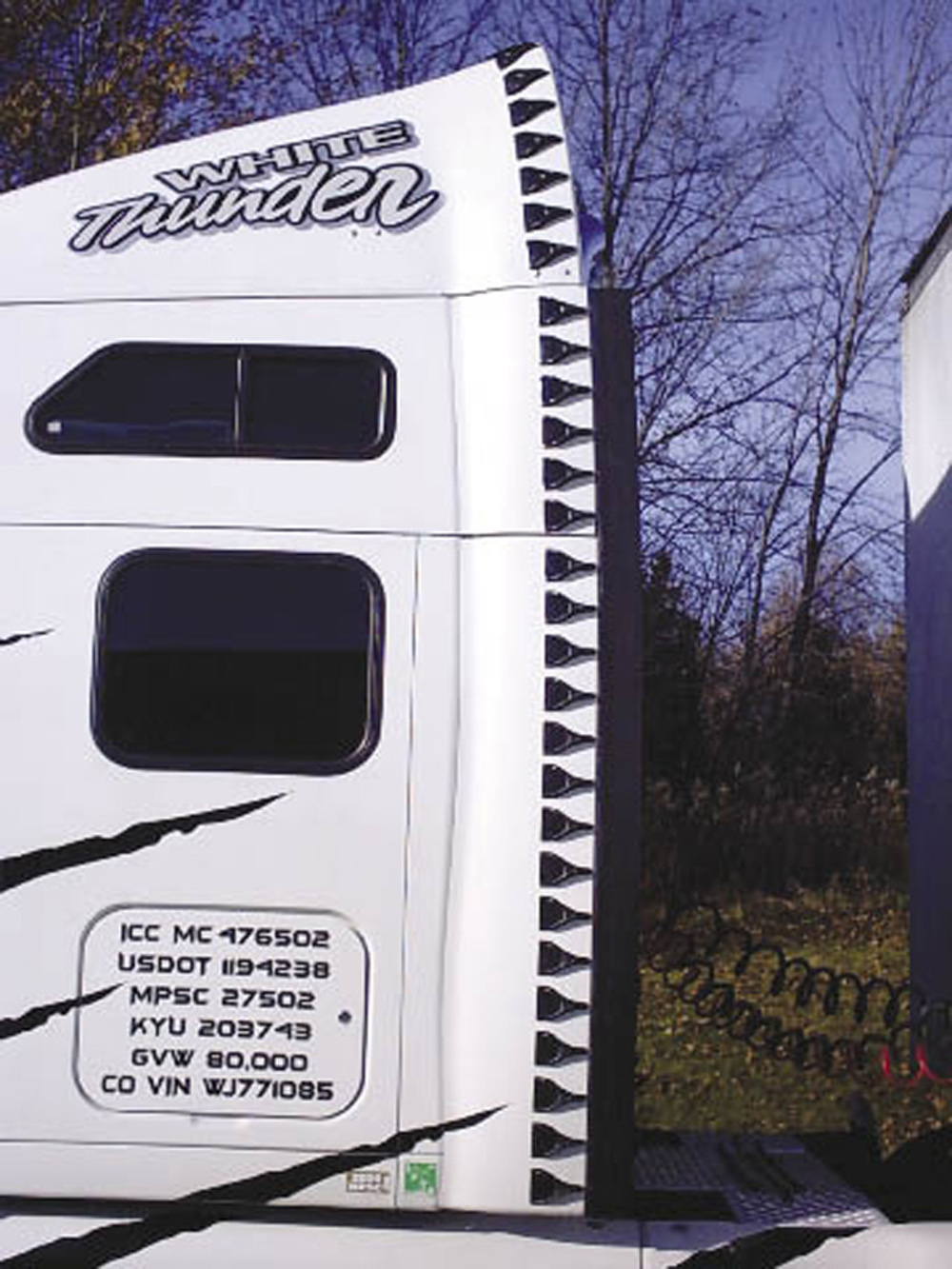

A partnership between west and east coast NASA centers that began in the 1970s led to a new approach to streamlining designs for the tractor trailers vital to the continuous flow of goods on the nation’s roads. Resulting from studies first proposed by NASA Armstrong aerospace engineer Edwin Saltzman, and in concert with a Langley research team, the eventual development of small “vortex generators” – originally investigated to improve aircraft performance – enabled reshaping of the air flow around the big rigs. The newest versions of a commercially available product – lightweight devices that resemble hand-size, hollowed-out shark’s teeth – smooth air turbulence, reduce fuel use, and, in some cases, improve rear and side views in wet or snowy weather.

Perhaps most importantly, drivers of vehicles so outfitted have reported improved stability and handling and dramatically reduced fishtailing, potentially causing catastrophic loss of control: a crucial consideration for the double trailers driven in North America and the famous quad-trailer “road trains” that traverse the Australian Outback.

Space-Inspired Safety NASA research into flexible, high-temperature space materials may improve the personal shelter systems deployed by firefighters to survive raging wildfires. Langley has worked with the U.S. Department of Agriculture’s Forest Service to see if atmospheric-reentry materials capable of protecting spacecraft innards from temperatures exceeding 3,000 degrees Fahrenheit (1,649 degrees Celsius) could work terrestrially and still meet all firefighter requirements.

Current Forest Service versions are aluminized cloth tents, shaped like a half-cylinder with rounded ends. They reflect radiant heat and provide a certain amount of breathable air, but can be damaged by extended and direct contact with flame. Langley’s initiative, known as CHIEFS, which stands for Convective Heating for Improvement for Emergency Fire Shelters, has screened candidate materials using a number of test and design methods. Researchers have presented preliminary thermal test results to the Forest Service, with the eventual hope that full-sized prototypes could be manufactured and tested under rigorous real-world conditions.

Closer to home, smoke inhalation injury from the noxious products of fire combustion accounts for as much as 80 percent of fire-related fatalities. Most of these are preventable. Enter South Carolina-based Smoke Mask, Inc. (SMI), which has licensed a specialty catalyst developed at Langley. The device, derived from research involving space-borne carbon-dioxide lasers, converts carbon monoxide to nontoxic carbon dioxide, and removes other health-threatening compounds, such as formaldehyde and certain varieties of hydrocarbons.

SMI has used the catalyst in development of a personal “escape hood,” integrating the company’s customized filter with a flame-retardant material. The hood has a transparent front, an exhalation valve to prevent carbon dioxide build-up, and a drawstring to ensure a tight fit. Targeted for emergency use at home, work and school, as well as for professional firefighting and rescue efforts, the hood is designed to be donned in 10 seconds or less and will supply breathable air for 20 minutes, enabling quick flight from breathing hazards.

That same Langley-developed catalyst has also found use on nationwide racetracks. Penske Racing in North Carolina designed a Thermos-bottle-size filtration unit, part of a compound filter system containing absorbents and other materials to effectively remove noxious gasses from a driver’s interior air stream. Cleaner air virtually eliminates carbon monoxide poisoning and the resulting flu-like symptoms, like headaches, fatigue, and dizziness that traditionally lingered for days after races as drivers chased one another in packs around the track.

Streamlined for Sport Although not all Langley invention is racecar-fast, speed can factor in in unusual ways. That’s certainly the case with Langley’s 2008 development of a fabric for the Olympics-bound U.S. swim team. Because of Langley’s expertise and experience in aircraft drag reduction, Warnaco Inc., the U.S. licensee of the Speedo swimwear brand, approached its researchers for help in developing fabrics to enable the team to slice more efficiently through the water, helping to reduce the almost one-third of the total restraining force that constrains a swimming speed.

Roughly 60 fabrics or patterns were evaluated in one of Langley’s small low-speed wind tunnels to pinpoint the least-drag version. Speedo’s research and development team, Aqualab, leveraged the results to create a swimsuit the company asserted was its most hydrodynamically advanced version. Swimmer Michael Phelps, who lauded the new fabric in a joint New York City appearance with Langley researcher Steve Wilkinson, would, by 2016, become the most decorated Olympian of all time, with a total of 28 medals, 23 of them gold.

But even armchair non-Olympians can benefit from NASA technology transfer. A Langley biofeedback system initially intended to identify and combat boredom and inattention for pilots and air traffic controllers was licensed to SmartBrain Technologies, which used it in working with children afflicted with attention deficit/hyperactivity disorder. A follow-on version, now known as Mindshift, has a decidedly 21st century flavor: boosting video-game player performance. An added bonus is that screen-fixated players don’t have to fret that they’re missing too many aerobics classes: properly applied, the system can actually reduce stress and improve health. The system doesn’t, however, suggest the type and quantity of snack food that should be consumed throughout.