Editor’s note: Teams added an additional integrated ground systems operation to test the new uninterruptable power supply for mobile launcher 1 while it’s inside NASA Kennedy’s Vehicle Assembly Building for Artemis II rocket stacking operations.

Engineers are gearing up for a series of ground demonstration tests at NASA’s Kennedy Space Center in Florida to prepare for the agency’s Artemis II mission. These tests, known as integrated system verification and validation tests, will put the mobile launcher, Launch Pad 39B and in some cases, the four astronauts flying on the mission to work, evaluating that the ground equipment is ready to support launch.

“As we prepare for launch, it is critical for us to not only understand our systems and how they operate individually, but to be fully aware of how they perform together,” said Shawn Quinn, Exploration Ground Systems Program manager at Kennedy. “These tests enable the team to demonstrate new integrated processing and launch capabilities, as well as define operational procedures and schedules to ensure the team is ready for launch day.”

Most of the tests will take place while the mobile launcher is at Launch Pad 39B, which arrived at the launch site in August. Following completion of all the testing, teams will roll the mobile launcher to the Vehicle Assembly Building to prepare to integrate the Artemis II Moon rocket.

Test 1: Launch Day Demonstration

The first test, slated for September, demonstrates activities required to get the crew to their spacecraft and rocket on launch day. The crew will practice putting on their Orion crew survival system spacesuits in crew quarters at Kennedy’s Neil Armstrong Operations and Checkout Building and depart in their fully electric fleet of crew transportation vehicles to the launch pad. Upon arrival at the pad, the crew will head onto the mobile launcher and proceed to the crew access arm used to board Orion on launch day. While the SLS (Space Launch System) rocket and Orion will not be waiting for them this time, the test will help prepare the team for all the operations needed to get the crew to their ride to the Moon.

Test 2: Imagery Test

Engineers will verify that all the high-speed imagery cameras at Launch Pad 39B are functioning properly. Many high-speed cameras are used to monitor critical components and systems during the launch countdown and liftoff. The imagery also is used in detailed post-launch analysis. During one of the water flow tests, teams will test the cameras by setting them up in a launch countdown configuration. After the operation, which will last several hours, teams will analyze the footage to ensure each camera performed as expected.

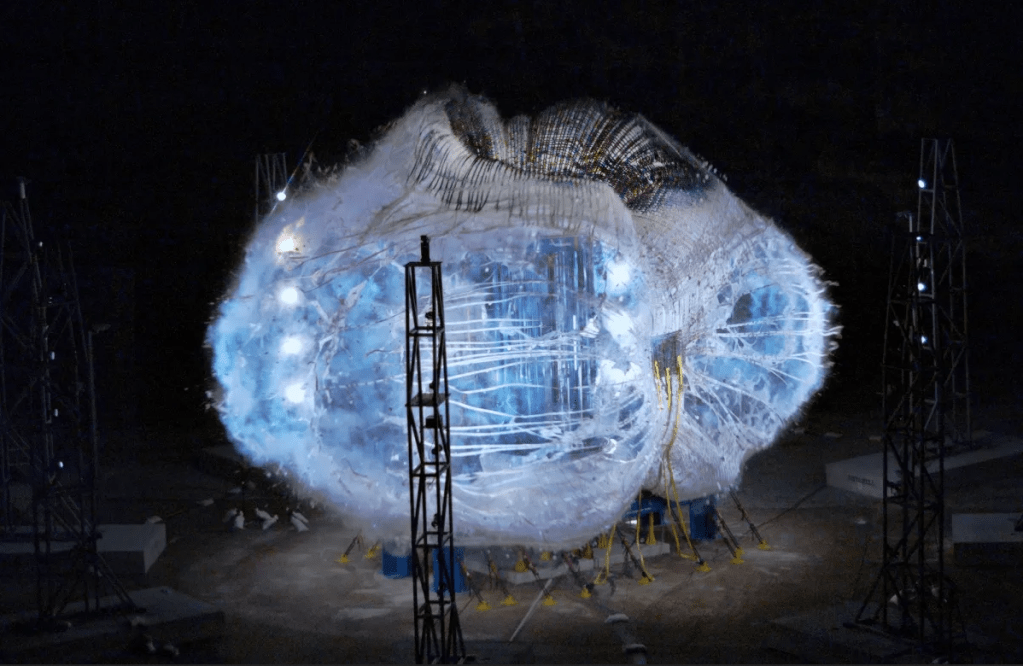

Test 3: Water Flow Tests

When the SLS’s solid rocket boosters ignite and the RS-25 engines start, the entire rocket will come to life, producing thunderous noise, heat, and energy. To ensure the crew, SLS, Orion, and ground structures are protected, teams will release approximately 400,000 gallons of water onto the mobile launcher’s deck, flame hole, and the pad’s flame deflector. Water helps deflect any over pressurization and suppress the sound produced at liftoff and is critical for launch success.

The ignition overpressure protection and sound suppression system will be tested over the course of several months while the mobile launcher is at the launch pad. During flow tests, this water deluge system will release enough water to fill 40 swimming pools from large overhead holding tanks to verify all systems are functioning as expected.

Test 4: Environmental Control System and Air and Gaseous Nitrogen Test

While the mobile launcher is at the launch pad, engineers will test the environmental control system to validate upgrades and demonstrate launch timeline procedures. This system provides air supply, thermal control, and pressurization to SLS and Orion while at the launch pad and during cryogenic propellant loading. During cryogenic loading, the environmental control system supplies an inert purge using gaseous nitrogen to specific compartments within Orion and SLS in order to maintain the correct environmental conditions produced during launch.

Test 5: Emergency Egress Demonstration

In the event of an emergency during the launch countdown that requires the astronauts to evacuate Orion, they and pad personnel will proceed to the emergency egress baskets, which are suspended from a catenary system on the mobile launcher. From there, they would travel down to emergency transport vehicles located at the base of the launch pad to drive them safely away.

For this test, which will last approximately one week, teams will practice operating the emergency egress system during daylight and at night to account for the various scenarios when launch may take place. Teams will train leaving the crew access arm and heading to the terminus area down at the pad.

While the crew and other personnel would ride the emergency egress baskets to the terminus area in a real emergency, no one will ride in the baskets for this test. Instead, teams will test the baskets during separate occasions by using water tanks filled to different levels to replicate simulate the weight of passengers.

Test 6: New Liquid Hydrogen Tank Flow Test

To minimize time between launch attempts, NASA built an additional liquid hydrogen sphere tank at the launch pad. Teams will practice two separate flow tests to practice flowing the super-cool liquid gasses. During the first test, teams will flow both liquid hydrogen and liquid oxygen from the original liquid hydrogen and the liquid oxygen tanks while the mobile launcher is at the launch pad. The next test will take place when the mobile launcher returns to the Vehicle Assembly Building (VAB) for rocket stacking operations. Teams at the pad will practice only flowing liquid hydrogen from both tanks to ensure they function properly and can safely flow the super-cool liquid gas to the mobile launcher and SLS during launch countdown.

Once the SLS elements are stacked, teams will demonstrate fueling operations at the pad, which will allow an opportunity to test the new tank with the mobile launcher and Artemis Moon rocket prior to launch.

Test 7: Firing Room Testing

Engineers will test all components in the firing room of the Launch Control Center, like software, audio loops used for communication, imagery, and more. For this specific evaluation, teams will test the audio loop the launch team uses to communicate with astronauts inside Orion during the launch countdown, as well as a switch that would be used in the unlikely event that a pad abort is required.

The approximately 10-day Artemis II flight will test NASA’s foundational human deep space exploration capabilities, the Space Launch System rocket and Orion spacecraft, for the first time with astronauts and will pave the way for lunar surface missions, including landing the first woman and first person of color on the Moon.

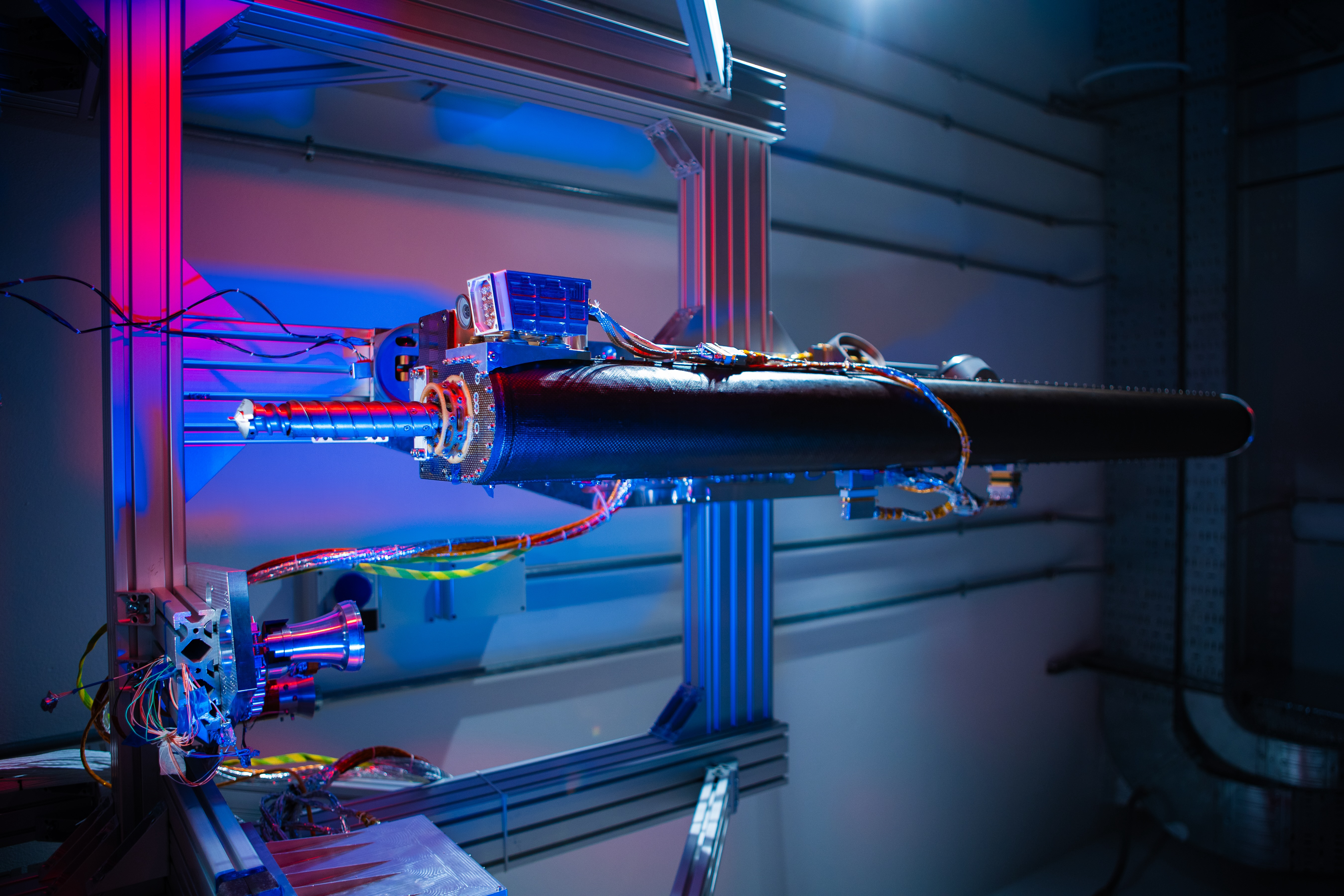

Test 8: Verify New Batteries Inside VAB High Bay 3

Teams will test out the new uninterruptable power supply for mobile launcher 1 while it’s inside Kennedy’s VAB for Artemis II rocket stacking operations. During this test, engineers will turn off the power to the mobile launcher and verify the new batteries, which are located in High Bay 3 of the VAB, do not negatively impact any systems aboard. These batteries provide power to the mobile launcher and allow teams the ability to safe all systems in the unlikely event the structure loses power while it’s inside the VAB. There are similar batteries that are used for the same purpose at Launch Complex 39B.