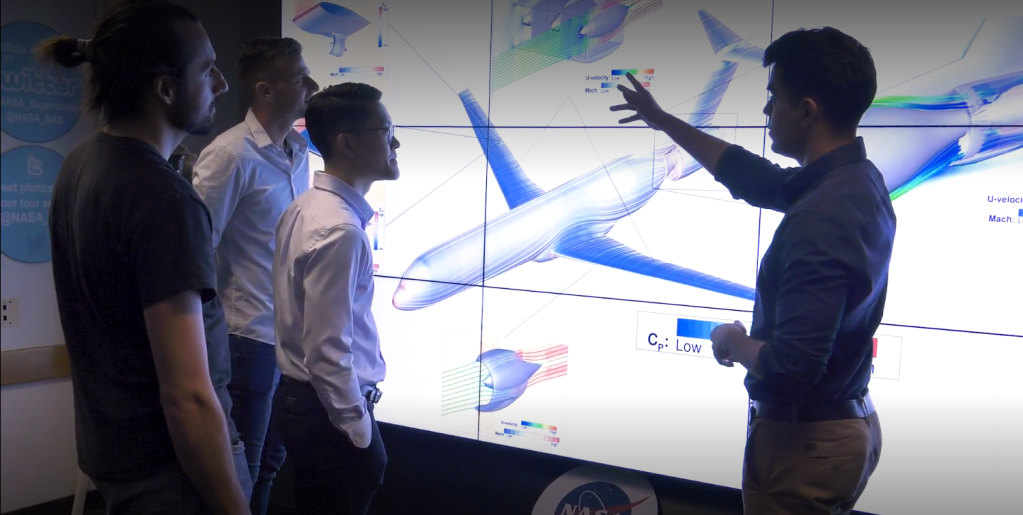

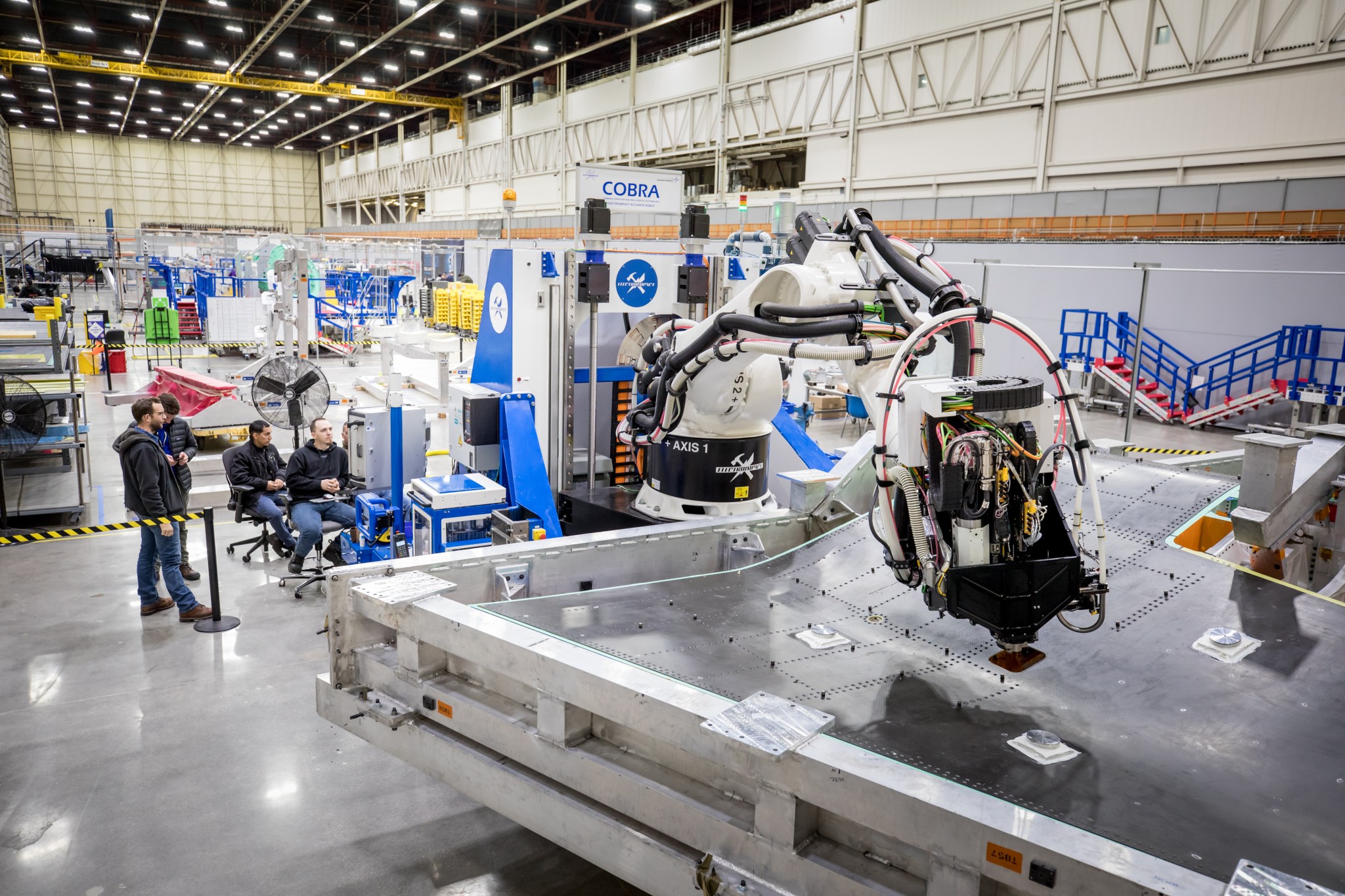

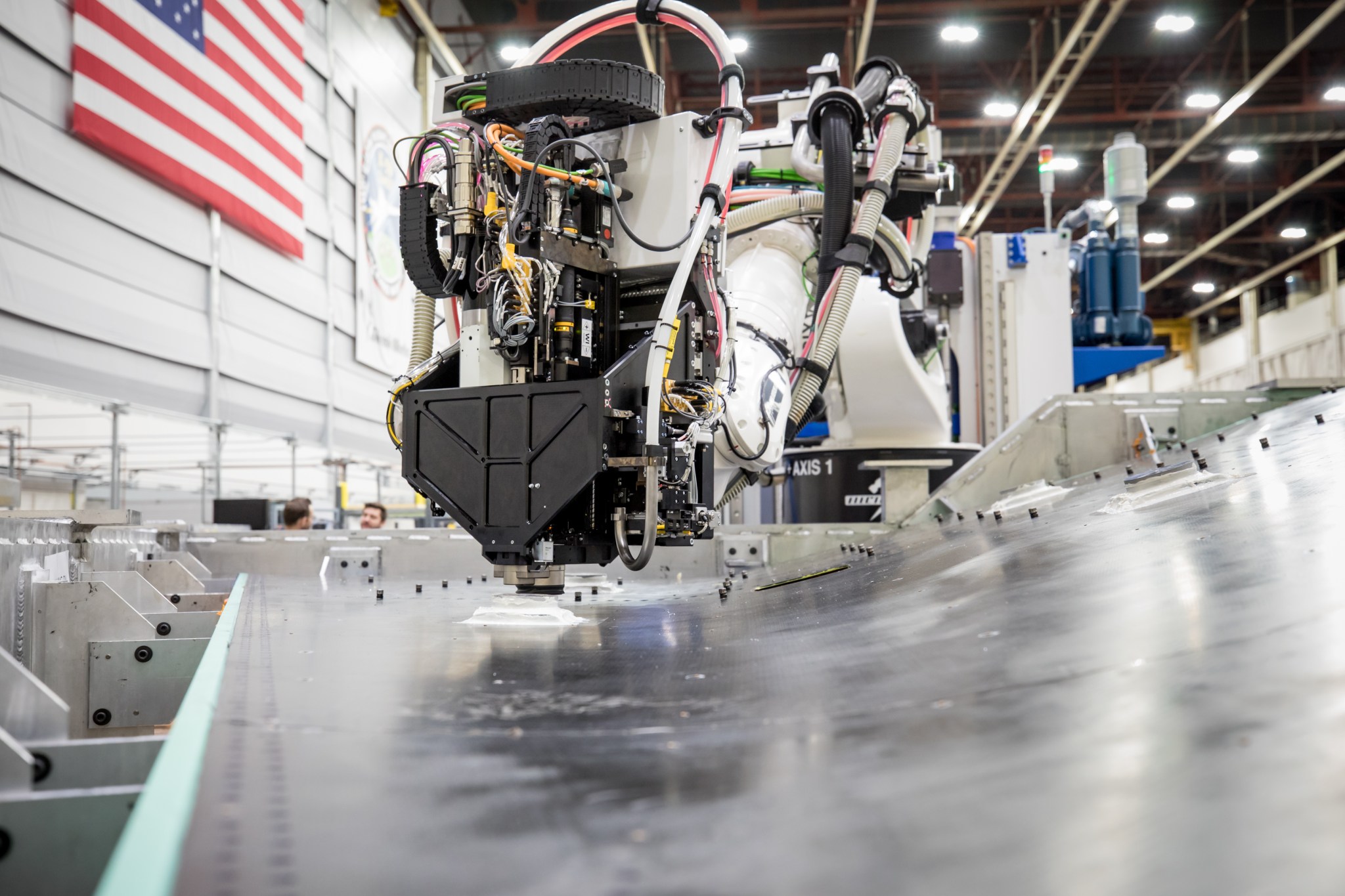

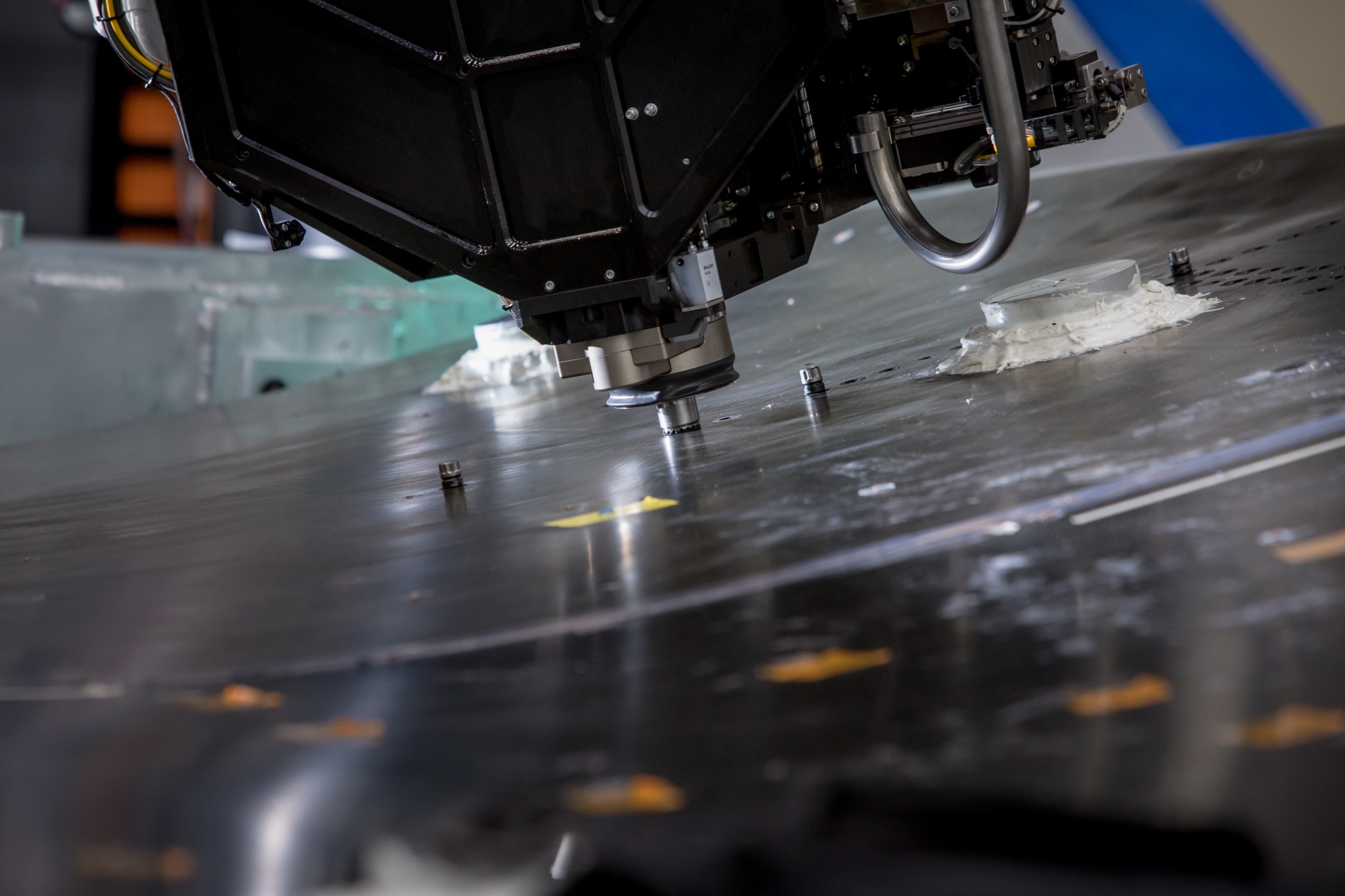

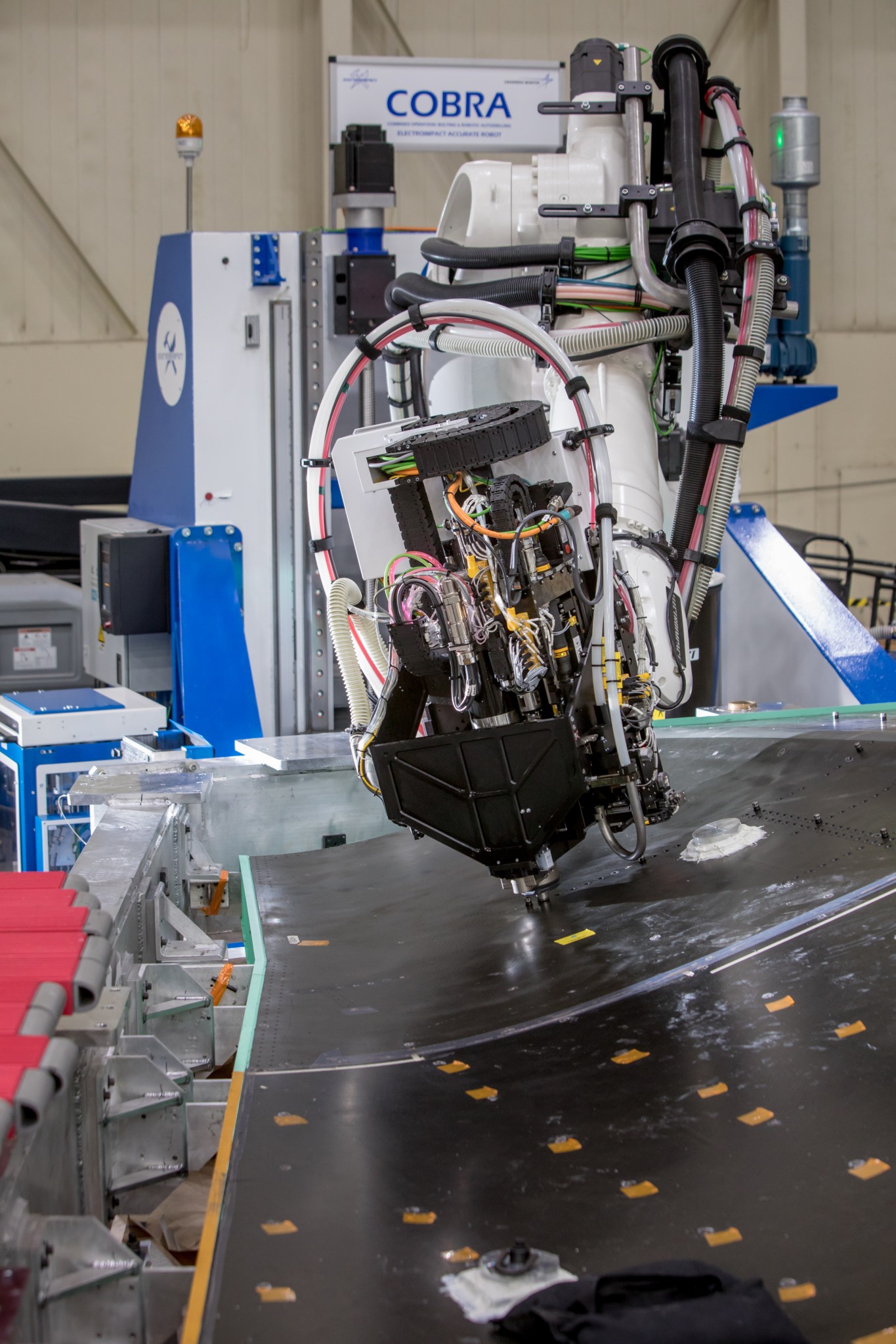

Assembly work on NASA’s X-59 Quiet SuperSonic Technology, or QueSST, aircraft continues to march on at a steady pace, as the main wing nears completion at the Lockheed Martin Skunk Works® facility in Palmdale, California. Aided by robotic technology, the X-59 QueSST team recently finished drilling the composite wing skins by utilizing a Combined Operation: Bolting and Robotic AutoDrill system, simply known as COBRA. The automated robotic system removes the necessity of multistep labor-intensive operations: drilling, countersinking and inspecting holes all at once, combining what would have traditionally taken multiple personnel to complete into a single process. The automated machinery marks a step forward in the manufacturing speed and accuracy of the X-59, as all inspection records are digitally recorded and later reviewed in developing the next stage of precision crafted parts for the aircraft.

Automated systems such as the COBRA are just one of many advanced tools NASA and the Skunk Works team is leveraging to make the Low-Boom Flight Demonstration a success. Progressing forward, the team will continue to work on the single-piece wing, center fuselage and empennage structural sub-assemblies.