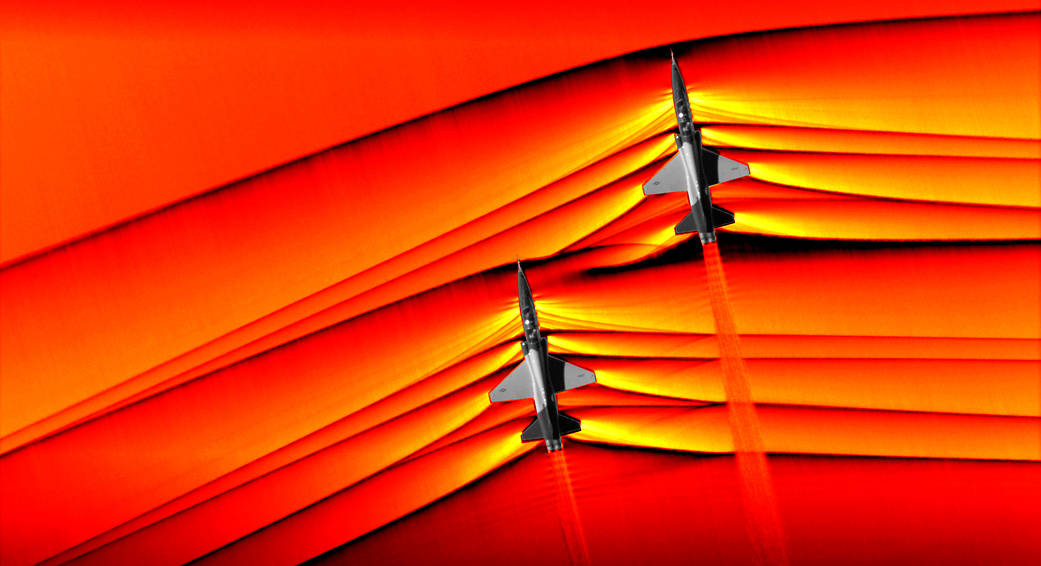

Upside down can be right side up. That’s what NASA researchers determined for tests of an efficient wing concept that could be part of the agency’s answer to making future aircraft sustainable.

Research from NASA’s Advanced Air Transport Technology project involving a 10-foot model could help NASA engineers validate the concept of the Transonic Truss-Braced Wing (TTBW), an aircraft using long, thin wings stabilized by diagonal struts. The TTBW concept’s efficient wings add lift and could result in reduced fuel use and emissions for future commercial single-aisle aircraft. A team at the Flight Loads Laboratory at NASA’s Armstrong Flight Research Center in Edwards, California, are using the model, called the Mock Truss-Braced Wing, to verify the concept and testing methods.

The model wing and the strut have instruments installed to measure strain, then attached to a rigid vertical test frame. Wire hanging from an overhead portion of the frame stabilizes the model wing for tests. For these tests, researchers chose to mount the 10-foot-long aluminum wing upside down, adding weights to apply stress. The upside-down orientation allows gravity to simulate the lift a wing would experience in flight.

“A strut reduces the structure needed on the main wing, and the result is less structural weight, and a thinner wing,” said Frank Pena, NASA mock wing test director. “In this case, the test measured the reaction forces at the base of the main wing and at the base of the strut. There is a certain amount of load sharing between the wing and the strut, and we are trying to measure how much of the load stays in the main wing and how much is transferred to the strut.”

To collect those measurements, the team added weights one at a time to the wing and the truss. In another series of tests, engineers tapped the wing structure with an instrumented hammer in key locations, monitoring the results with sensors.

“The structure has natural frequencies it wants to vibrate at depending on its stiffness and mass,” said Ben Park, NASA mock wing ground vibration test director. “Understanding the wing’s frequencies, where they are and how they respond, are key to being able to predict how the wing will respond in flight.”

Adding weights to the wingtip, tapping the structure with a hammer, and collecting the vibration response is an unusual testing method because it adds complexity, Park said. The process is worth it, he said, if it provides the data engineers are seeking. The tests are also unique because NASA Armstrong designed, built, and assembled the wing, strut, and test fixture, and conducted the tests.

With the successful loads calibration and vibration tests nearly complete on the 10-foot wing, the NASA Armstrong Flight Loads Laboratory team is working on designing a system and hardware for testing a 15-foot model made from graphite-epoxy composite. The Advanced Air Transport Technology TTBW team at NASA’s Langley Research Center in Hampton, Virginia, is designing and constructing the model, which is called the Structural Wing Experiment Evaluating Truss-bracing.

The larger wing model will be built with a structural design that will more closely resembles what could potentially fly on a future commercial aircraft. The goals of these tests are to calibrate predictions with measured strain data and learn how to test novel aircraft structures such as the TTBW concept.

NASA’s Advanced Air Transport Technology project falls under NASA’s Advanced Air Vehicles Program, which evaluates and develops technologies for new aircraft systems and explores promising air travel concepts.