Understanding what stress, or strain, an aircraft can endure is critical to carrying out its intended mission. To better understand the aircraft’s capacity for strain, unique facilities can “load” the aircraft to specified stress points and document its performance.

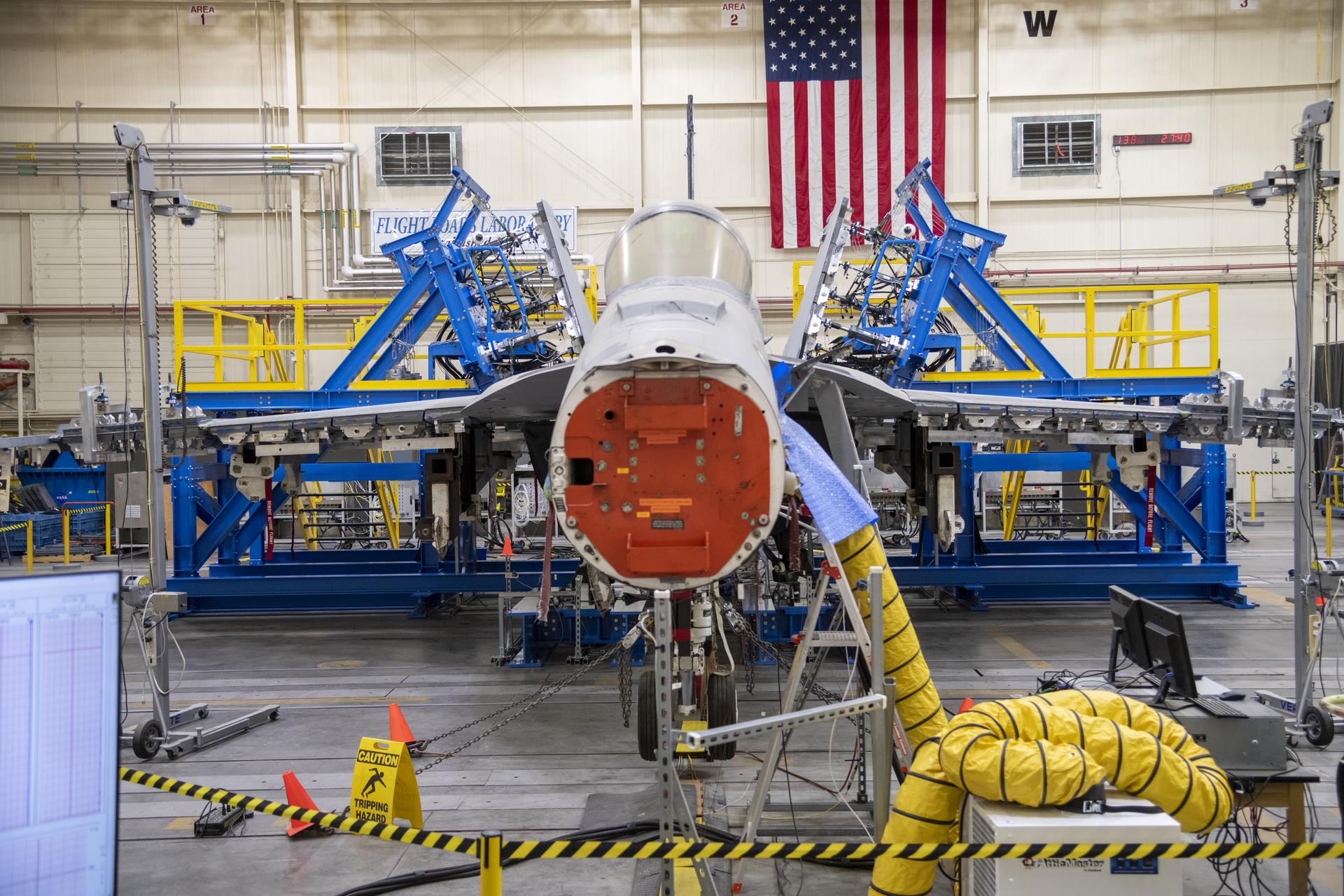

Recently, that kind of loads calibration testing on the Navy’s F/A-18E Super Hornet aircraft was completed at the NASA Armstrong Research Center’s Flight Loads Laboratory in Edwards, California. The calibration established the correlation between strain gauges installed on the test aircraft and forces experienced by the F/A-18E structure during flight.

The aircraft was flown to NASA Armstrong from the Naval Air Systems Command (NAVAIR) Air Test and Evaluation Squadron VX-23 located in Patuxent River, Maryland. The NASA Armstrong team assisted in preparing this F/A-18E aircraft for its new role as the Navy’s next loads test aircraft.

The test data resulted in the development of loads equations that calculate real-time loads experienced during flight testing, which can be compared to established design limits to ensure safety of flight and crew. The aircraft can then be used to clear new structural modifications and payloads to the F/A-18E design limits.

Currently, NAVAIR is using NASA facilities to restore the aircraft from its testing configuration by removing test equipment, reinstalling hardware, and the landing gear, and preparing it for a return to its test squadron.

The recently concluded third and final testing phase involved loads calibration testing of the vertical tails.

“The lessons learned during the wing testing (the second phase that concluded in March) was applied to the vertical tail tests and it resulted in a very efficient testing activity,” said Larry Hudson, NASA Armstrong Flight Loads Laboratory chief test engineer. “We completed the tests in three days.”

The first phase of loads calibration testing focused on the aircraft’s horizontal tails and concluded in October 2021.

It was a strong finish for a resilient and focused project team that faced a steep climb with a pandemic, challenges with procuring materials to make some of the test structures, and the loss of a colleague.

“It was difficult at times and losing project manager Kim Tucker was emotionally challenging for us,” Hudson said. “Everyone worked well together, and it really was a perfect example of a team effort. The team was committed to getting the job done as quickly as possible, without compromising safety, while providing the high-quality data to the customer.”

The planning and teamwork paid off.

“Our goal when we test any customer supplied component or jet, is to return it undamaged (unless a test objective requires testing to failure),” Hudson said. “After 87 load cases, our test approach and systems were able to do just that – obtain quality test data and deliver the test article back undamaged.”

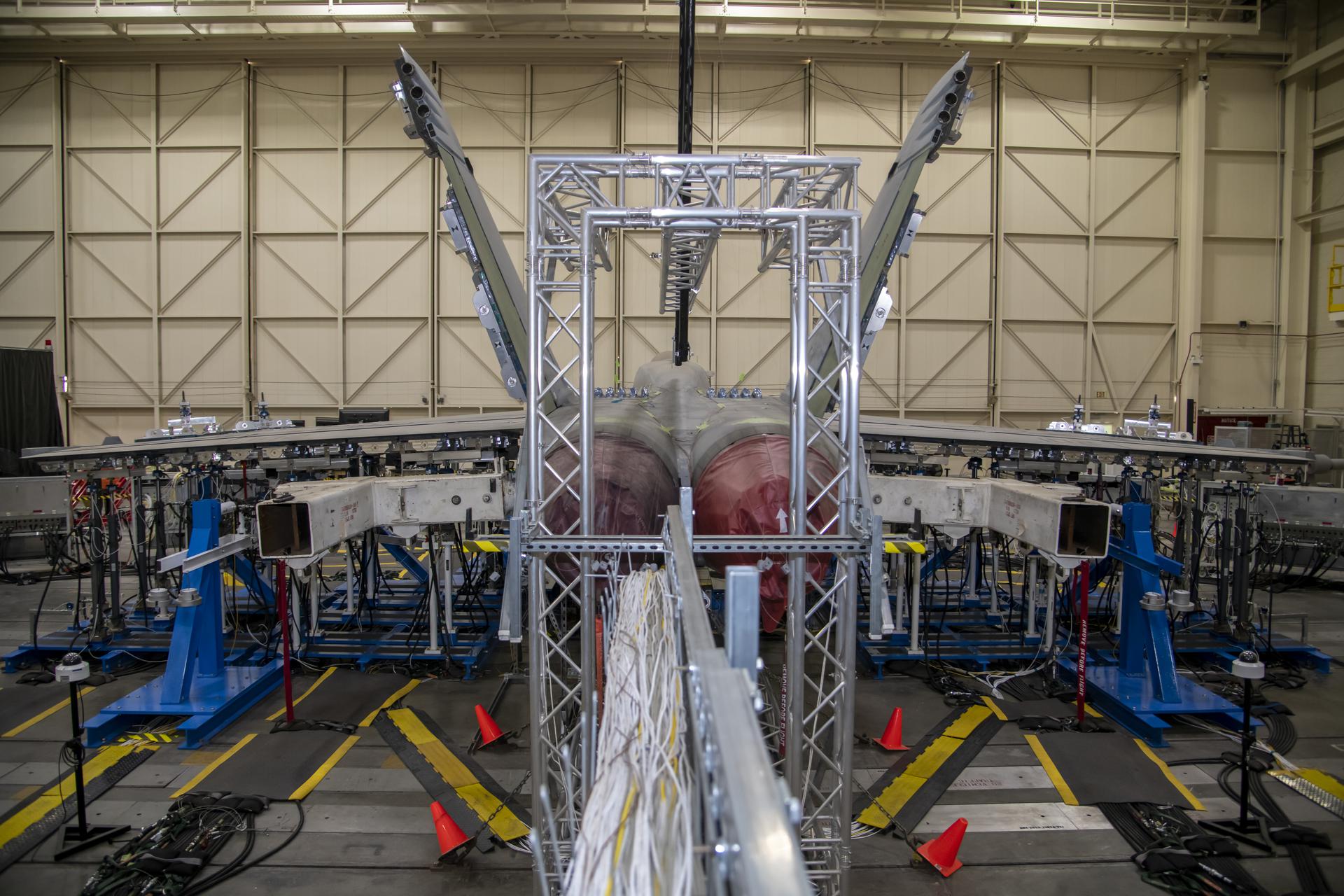

While the wing tests were the most complex given the number of actuators involved, the vertical tail had its own complexities due to the height above the ground and the precise alignment of two 20,000-pound structures that were assembled away from the aircraft and then rolled forward for connect to the aircraft.

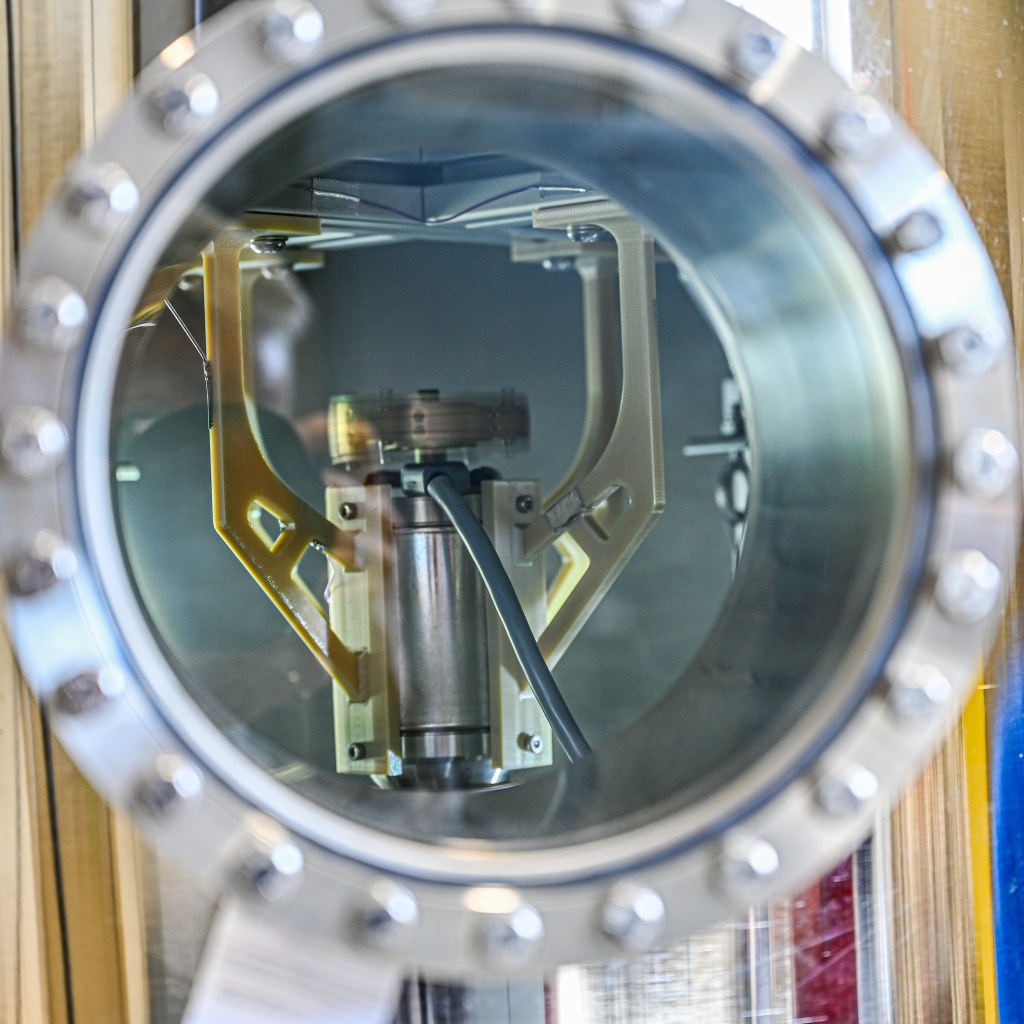

Testing included the operation of 84 hydraulic actuators during the performance of 87 load cases, including the simultaneous operation of 56 actuators, making it one of the most complex loads calibrations testing the lab has encountered. A load case consists of a distributed pressure load applied to the structure, and sensors recording the response.

“The project was good for the branch and for NASA Armstrong,” said Keerti Bhamidipati, interim flight loads laboratory project manager said. “It sharpened our critical skill sets, and our technicians and engineers exercised flight loads laboratory practices to work through technical challenges and gain efficiencies. At the start of the horizontal tail testing our test cadence was a couple of load cases per day. By the end, we completed the vertical tail testing in just two and a half days.”

While the NASA Armstrong Flight Loads Laboratory might not know what the next major project is, it stands ready to meet future aerospace challenges.