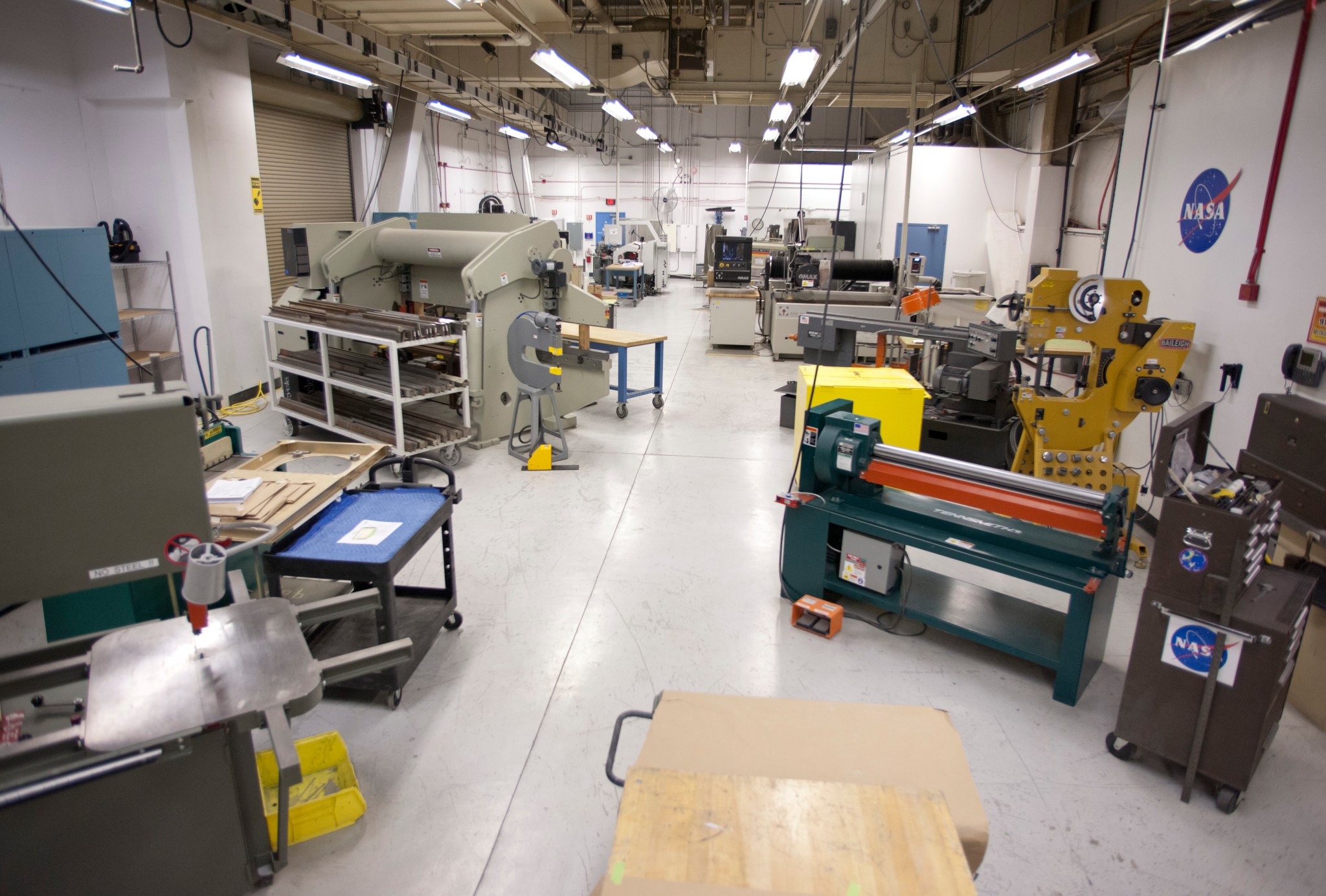

NASA’s Armstrong Flight Research Center Building 703 Fabrication Shop in Palmdale, California, is a first response manufacturing, modification, and repair center supporting NASA scientific platform aircraft and related experimental hardware. While the primary focus is to support Building 703 activities, the shop also provides manufacturing, modification, and repair assistance to operations at Armstrong’s Edwards, California, location.

The Building 703 Fabrication Shop maintains a 4,000-square-foot fabrication facility with a staff of expert machinists, sheet metal/composite technicians, and welders with an average of more than 20 years experience. With their valuable proficiency, technicians work hand-in-hand with engineering staff, providing advice, troubleshooting design problems, and creating prototypes that are then reverse-engineered for future assemblies.

With the ability to perform precision machining, sheet metal fabrication, composite, and welding capabilities, the master craftsmen in the Fabrication Shop support fabrication of a wide spectrum of aircraft, flight hardware, ground support equipment, test hardware, and facility hardware. Expert technicians have extensive experience with metals such as aluminum, carbon, and alloy steels as well as exotic alloys like Monel®, Inconel®, and titanium.

Our machinists are capable of designing and manufacturing prototype hardware, machining complex surface profiles and holding extremely tight tolerances (+-.0002 are the norm). They have extensive experience with CAD/CAM software including Pro/E, EZcam, Master cam, and OMAX. Technicians manufacture parts from customer-provided 2-D or 3-D CAD files or produce CAD files to customer requirements.

The sheet metal/composite technicians bring to the table multiple skills and are routinely tasked to perform back shop functions, fabricating experimental components with tightly held tolerances as well as working in the hangar performing heavy structural modifications to the aircraft. Technicians are also tasked with repairs and modifications to the composite components on the aircraft. Even though the technicians are proficient with all of the tasks listed they each have their own specialty, which greatly enhances the capability of the shop.

The machinists also have extensive experience and offer support with a more complicated type of fabrication. This type of machining can include complex surface profiles and compounded angles. The ability to hold extremely tight tolerances to ± 0.0002 are the norm. These machinists also have a vast level of experience machining aluminum, steel, stainless steels, and alloys such as Monel®, Inconel®, and titanium.

The welders are certified in all pertinent materials related to aircraft and construction. A Certified Welding Inspector (CWI) is also on staff.

Fabrication Shop technicians have extensive knowledge with CAD/CAM software including Pro/E, EZcam, Master cam, and OMAX. Shop personnel can manufacture parts from customer-provided 2-D or 3-D CAD files or produce CAD files to customer requirements. CAM Capabilities include 2 CNC Mills, 1 CNC Machining Center, 1 NC Lathe, and 1 Waterjet.

The Fabrication Shop has state-of-the-art computer numerically controlled (CNC) milling capabilities. Additional CNC milling capabilities include a vertical machining center 30 x 16 x 20 in., 21-position tool changer, 3 axis capabilities. Milling operations are performed on very precise, CNC milling machines with commonly held tolerances to ± 0.0002 in. CNC Lathe Capabilities are also available with a 10” swing and 30” travel. Waterjet capabilities are 48” X 48” (X&Y). A 5-axis CNC press brake, rated at 175 tons that can bend up to 1″-thick steel plate. The press brake is also capable of bending parts up to 12′ in length. All of the necessary support equipment is also on site such as brakes, shears, saws, lathes, etc.