A group of undergraduate students at Virginia Tech are working on a system that can 3D-print a whole drone and have it fly off the printer fully operational.

Through the project they named Robotic Aerial Vehicle Fabricator (RAV-Fab), the students have seen significant success in their research with help from NASA’s University Student Research Challenge (USRC).

Each year, USRC invites students across the country to contribute to NASA’s research goals by creating new solutions to the aeronautical challenges faced in 21st century aviation.

Through USRC, these students get to interact with real-world procedures both in and out of the lab. They get to manage their own research project, utilize state-of-the-art technology, and work alongside accomplished aeronautical researchers. They are not only being included but are contributing, as well.

USRC doesn’t only provide experience in technical research, however. Though each team of students selected receives a partial grant from NASA, the rest of their USRC funding is secured through student-led crowdfunding to help them develop skills in entrepreneurship and public communication.

Automated Drone Manufacturing

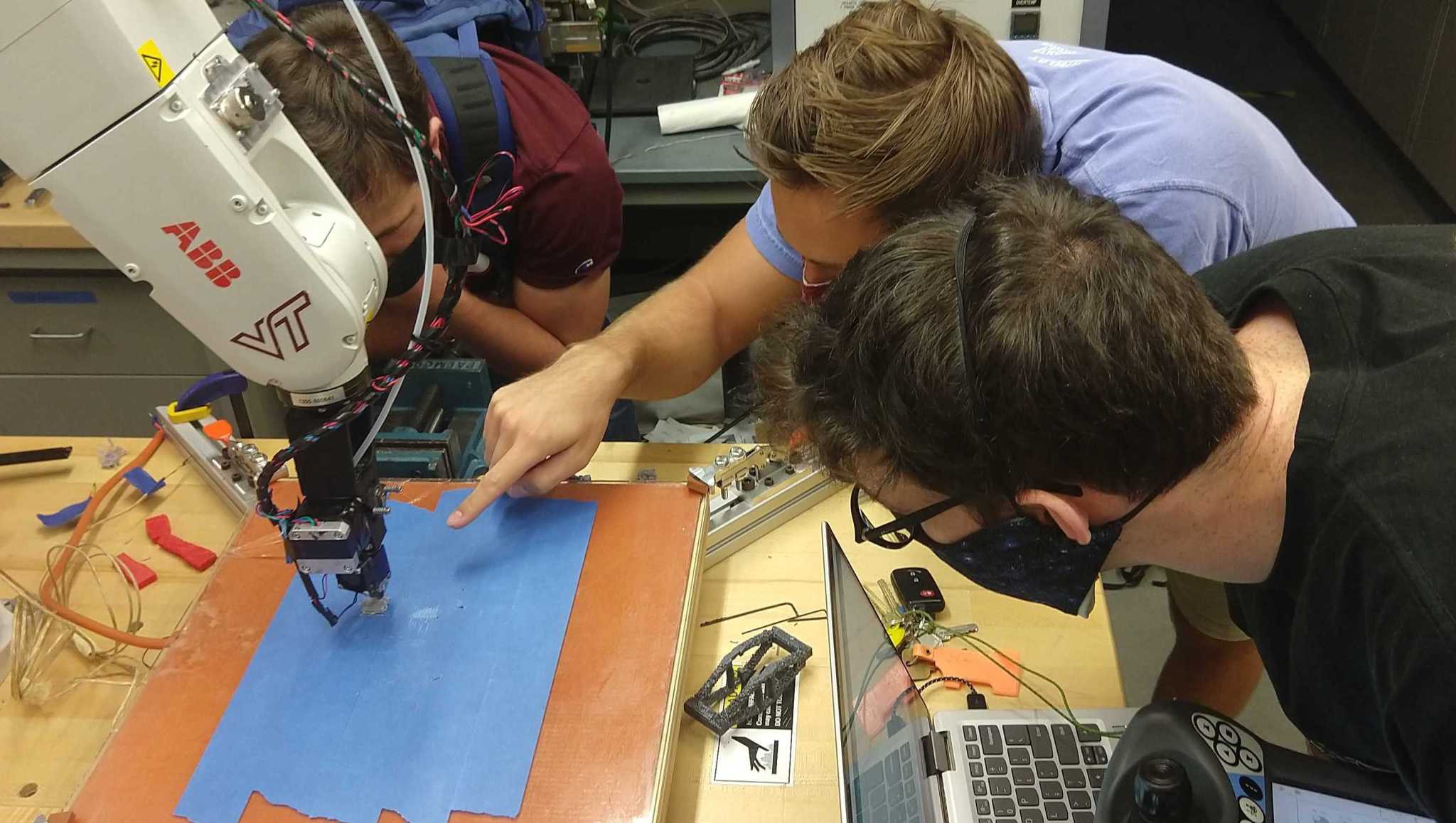

The RAV-Fab group first started working on robotic 3D printing in Virginia Tech’s DREAMS Lab, led by Professor Chris Williams and advised by Joseph Kubalak.

Recognizing the potential in the concept, the students researched opportunities to make the vision become a reality. The group heard about USRC through faculty advisors at Virginia Tech, applied for a grant, and were awarded the funds by NASA in 2021.

3D-printing a fully operational drone and having it fly off the printer’s build plate has many use cases.

With the flexibility of 3D printing, drone manufacturers can rapidly fabricate drones with custom-built features – tailoring them to weather, payloads, or other mission-specific items – all using the same device and framework.

Moreover, since RAV-Fab supports the entire drone construction process in one device, manufacturing can be decentralized so that operators can build the drones in multiple facilities that could be located virtually anywhere.

“As drones become part of our everyday lives, we’re going to need autonomous, localized manufacturing that serves local suburbs or neighborhoods. This device could reliably provide that for services like package delivery or agricultural surveys,” said Tadek Kosmal, a senior at Virginia Tech and principal investigator of RAV-Fab.

A key component of RAV-Fab’s research is modular construction. Though the 3D printer fabricates much of the drone, certain pre-built components such as the drone’s motors are “dropped in” by the device. Then, the 3D printing continues – encasing these components to complete the drone.

So far, the team has seen success with 1-foot wingspan drones and is moving up to larger sizes.

“We’re increasing the size of the robots we’re using for manufacturing. By increasing the size, we’ll be less constrained by our current robot’s smaller reach. It also allows us to incorporate real-time print and assembly sensing to bump-up the autonomy level,” said Kosmal.

Communication is Everything

Under Kosmal’s lead, the RAV-Fab team has managed a successful crowdfunding campaign with contributions from the public via their website. The students benefitted from the experience of communicating their work to new audiences.

“The crowdfunding initiative has been really helpful. We had to ask ourselves how to inform the public of this technology – particularly people who may just contribute smaller amounts of money. We learned to tailor information to them and get them excited and involved,” said Kosmal.

RAV-Fab took their crowdfunding even further, however. The group successfully pitched their concept to several aviation companies, including Boeing and Northrup Grumman, which then contributed funds to RAV-Fab’s research.

“We went to them and asked: ‘What do you need? How can we help you get to your long-term goals and visions?’ We learned a lot from their input. It helped us become better entrepreneurs,” said Kosmal.

Ultimately, USRC’s participants draw inspiration and drive for the research from their own passion in the topic. Much of the work occurs outside of their classes as an independent project. It is this passion that often leads students to success.

“When the students themselves are excited about their work, it’s easier to get others excited about it. Enabling the development of communication skills is an important element of USRC,” said Steven Holz, assistant project manager of the University Innovation project that manages USRC.

The Best is Yet to Come

Now, the students are completing their undergraduate education as fully-fledged researchers, just as their drones fly off the printer as fully-functional aircraft. Kosmal, who leads RAV-Fab as its principal investigator, observes that each team member has been invaluable to the project.

“This project wouldn’t be possible with without each member on the RAV-Fab team. Seeing everyone work together has been inspiring,” said Kosmal.

Though the USRC-funded period of RAV-Fab’s research ends this August, Tadek Kosmal and a few other students plan on continuing their research – taking it with them to graduate school, and even starting another round of crowdfunding.

“It’s the first time we’ve seen students go for a second round of crowdfunding in this way to get more interest in their project and continue their research,” said Holz. “It will be interesting to see where the students go.”

Beyond USRC, there are many ways RAV-Fab could move forward. The research could be transferred to another company, but Kosmal notes that the team could even found their own startup. In the meantime, RAV-Fab is seeking to increase its social media footprint and generate more interest.

On the opportunities NASA has provided him and his peers, Kosmal has nothing but positive reflections.

“If you told me a year ago that we’d be robotically fabricating fully-functional drones, I would have said: ‘No way.’ We have learnt to dream big. Breaking down big ideas is part of the trade and ultimately leads to success. I really like that aspect of USRC – be really creative, apply good engineering to it, and make it happen,” said Kosmal.

The next round of USRC solicitations are due June 23, 2022, once the submission period for proposals is opened. Check this page for more information and updates.