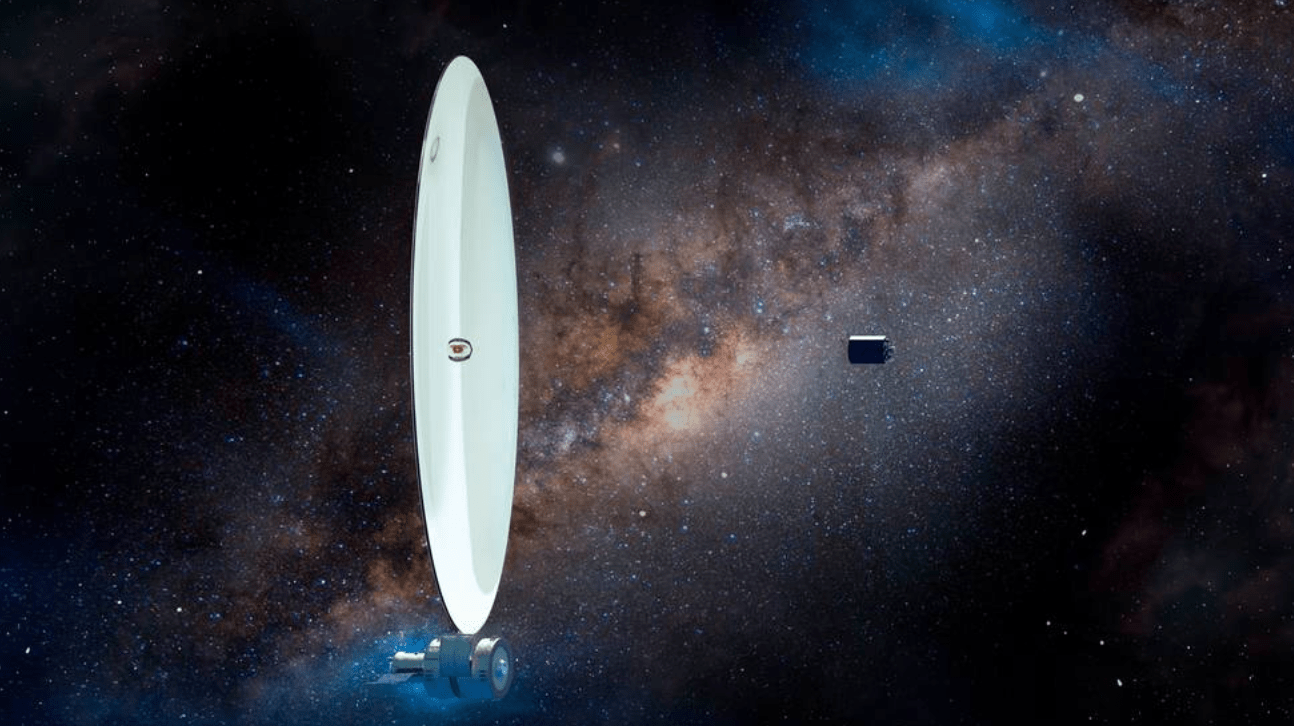

When it comes to telescopes, bigger is better. Larger telescopes collect more light and allow astronomers to peer farther into space and see distant objects in greater detail.

What if there was a way to make a telescope 10 times – or even 100 times – bigger than before? What started as a theoretical question is now a series of experiments to see if fluids can be used to create lenses in microgravity. The next experiment is stowed on the International Space Station National Laboratory waiting for the arrival of Axiom-1 astronauts to try it out, and is part of Ax-1 Mission Specialist Eytan Stibbe’s research portfolio.

It Starts with Fluids

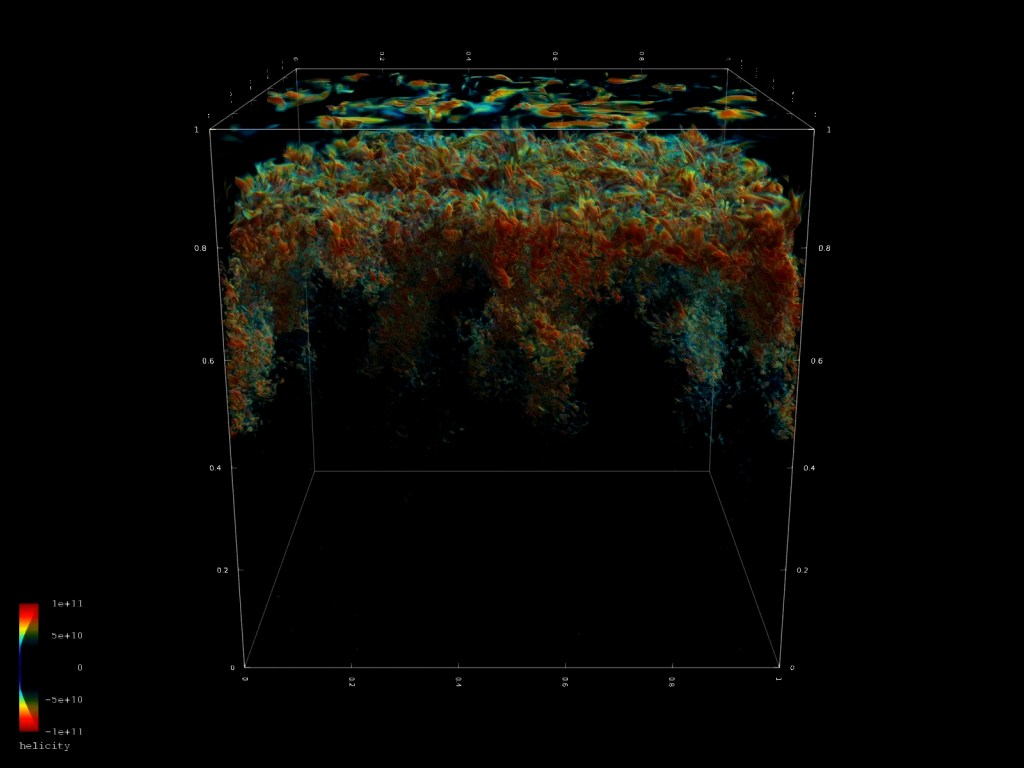

All liquids have an elastic-like force that holds them together at their surface. This force is called surface tension. It’s what allows some insects to glide across water without sinking and gives water droplets their shape. On Earth, when droplets of water are small enough (2 mm or smaller), surface tension overcomes gravity and they remain perfectly spherical. If a droplet grows much larger, it gets squished under its own weight.

But in space, blobs of water and other liquids (after wobbling about) eventually assume a perfect spherical shape.

Edward Balaban, principal investigator of the Fluidic Telescope Experiment, or FLUTE, at NASA’s Ames Research Center in California’s Silicon Valley teamed up with researchers at Ames, the agency’s Goddard Space Flight Center in Greenbelt, Maryland, and Technion – Israel Institute of Technology, to explore whether it was possible to make high-precision lenses and mirrors in space using liquids.

“We thought, why not take advantage of the way liquids naturally behave in microgravity and apply it to the construction of large-scale telescopes or space-manufactured optical components that can have all kinds of uses,” said Balaban. “In microgravity, liquids take on shapes that are useful for making lenses and mirrors, so if we make them in space, they could be used to build telescopes that are dramatically bigger than was previously thought possible.”

Ground Tests: A Drop in the Bucket

Before taking their ideas to the skies, the team wanted to test their ideas on the ground.

“Liquids are useful not only for creating the lenses themselves, but also as a mechanism to eliminate the effect of gravity in an experiment on Earth,” said Moran Bercovici, an associate professor of Mechanical Engineering at Technion.

“By injecting a liquid that can be solidified, into circular frames submerged in water, we were able to create lenses literally in a janitor’s bucket,” said Dr. Valeri Frumkin, who developed the method in Bercovici’s group. “Polymers, which are also used in nail salons to make acrylic nails or in adhesives like superglue, are a natural choice for lens material. The trick is to make sure that the water has the exact same density as the polymer we’re injecting so that the forces of buoyancy precisely oppose gravitational forces to simulate the conditions of weightlessness.”

The resulting lenses have an outstanding surface quality comparable or even better than achievable with the best polishing methods, and they took only a tiny fraction of the time to construct.

“This method allows us to completely skip any mechanical processes such as grinding or polishing,” said Bercovici. “The natural physics of fluids simply does all the work for us.”

Next Up: Testing in Microgravity

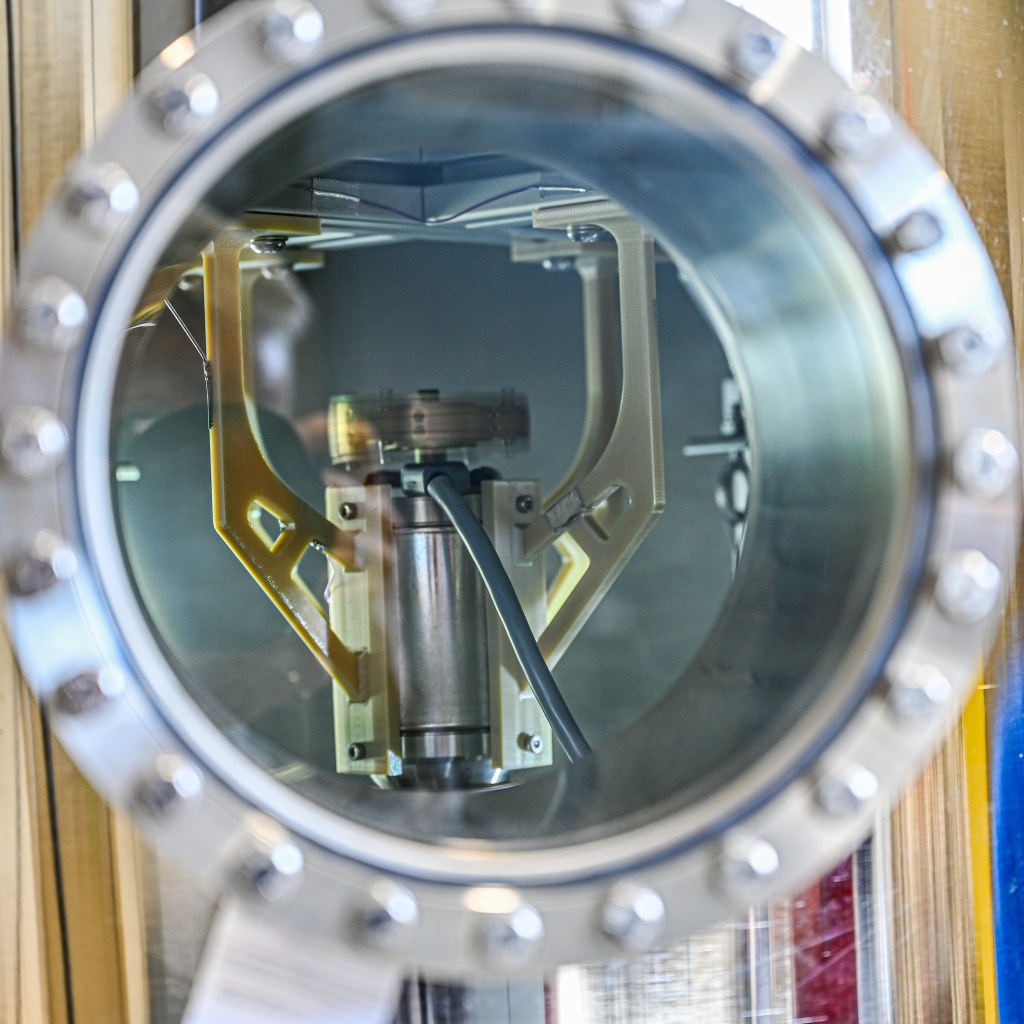

In December 2021, the team tried out their ideas on two ZeroG parabolic flights. The flights provided 50 opportunities to achieve 15 to 20-second periods of microgravity – long enough for the team to form liquid lenses and capture data to analyze whether they achieved their goals.

During the flight researchers used pumps to push synthetic oil into a circular frame (about the size of a dollar coin), letting the liquid fill the gap and momentarily achieve the desired shape. The oils are similar to automotive oil, with different levels of viscosities – or goopiness – to try out which works better.

“Sure enough, in a few seconds we were able to create a free-standing liquid lens – until the plane lifted upwards again and gravity kicked in and the oils oozed out,” said

Bercovici. “Our experiment on the space station will add a step to cure the fluids so they keep their shape.”

Using a laser to take ultra-fast and ultra-exact measurements, they were able to see the precise moment the liquid took shape.

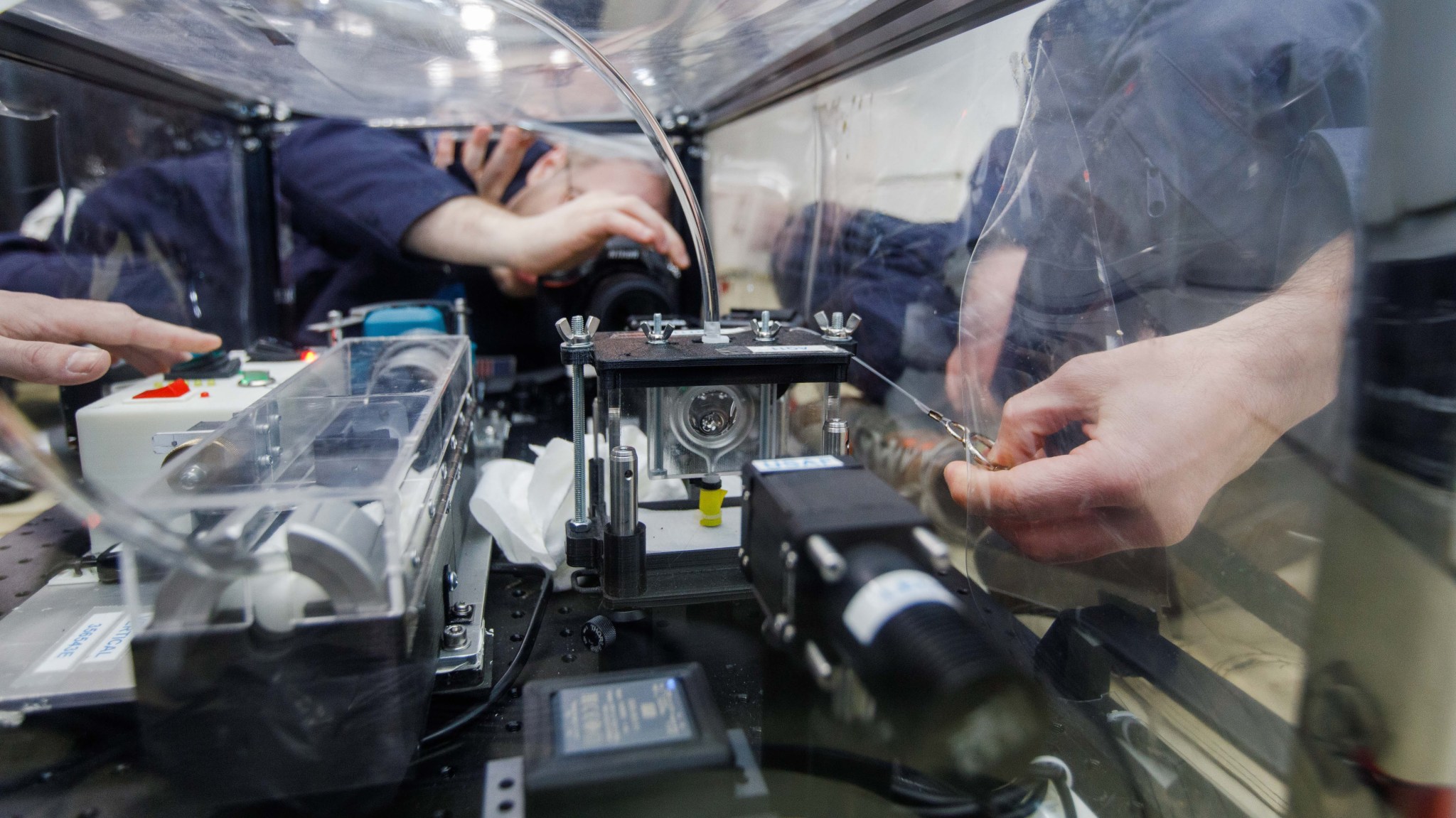

With the first round of parabolic flights successfully behind them, the team eagerly awaits their experiment aboard the orbiting laboratory. Ax-1 crew member Eytan Stibbe will perform the experiment and former NASA astronaut and Ax-1 commander Michael Lopez-Alegria will serve as his backup. The experiment will take place entirely in microgravity, again using liquid polymers (like the hardened lenses made in the lab at Technion) and will use either UV light or temperature to harden them in-orbit. The lenses will then return to Earth where researchers at Ames will study them.

“We expect this approach will create perfectly shaped and smooth surfaces: the best surfaces to turn into mirrors,” said Vivek Dwivedi, a FLUTE scientist at Goddard and expert in atomic layer deposition technology that could be used to make ultra-precise telescope mirrors in space.

“If our station experiment is successful, it will be the first time an optical component is made in space,” said Balaban. “It feels a bit like making history.”

The space station experiment is part of the Rakia Mission, led by The Ramon Foundation, and is supported by The Israeli Space Agency and the Israeli Ministry of Innovation, Science and Technology. NASA’s Space Technology Mission Directorate supports FLUTE through the Center Innovation Fund and the Flight Opportunities Program. FLUTE’s test aboard the space station is sponsored by the International Space Station National Laboratory.