Flight Loads Laboratory

The Flight Loads Laboratory (FLL) conducts mechanical-load and thermal studies of structural components and complete flight vehicles in addition to performing calibration tests of vehicle instrumentation for real-time determination of flight loads.

Chief aerostructures branch

Michael Yandell

chief engineer, fll

Larry Hudson

PROGRAM manager fll

Eugene Yerdon

operations manager, fll

Ray Sadler

Focus Areas and Capabilities

Learn more about the specifications and capabilities of the Flight Loads Laboratory.

Characteristics

Quick Facts

Capabilities

FLL Contact Information

Michael Yandell

Chief, Aerostructures Branch

(661) 276-3416

Larry Hudson

Chief Engineer, FLL

(661) 276-3925

Eugene Yerdon

Program Manager FLL

(661) 643-2124

Ray Sadler

Operations Manager, FLL

(661) 276-6148

Flight Loads Laboratory Fact Sheet

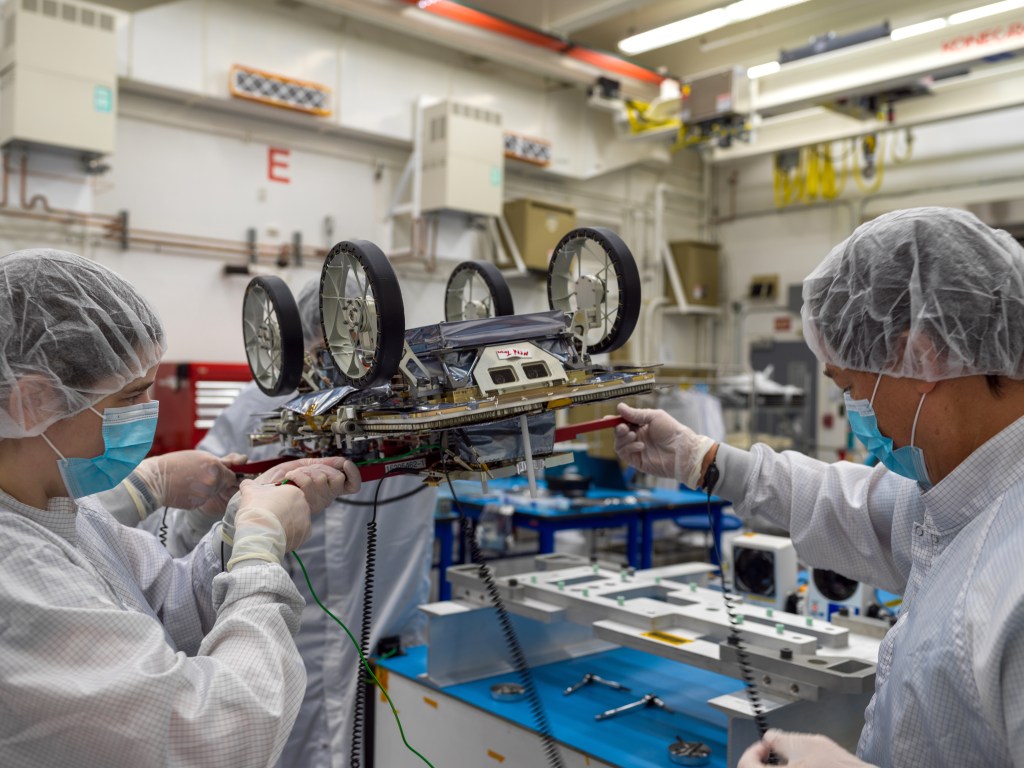

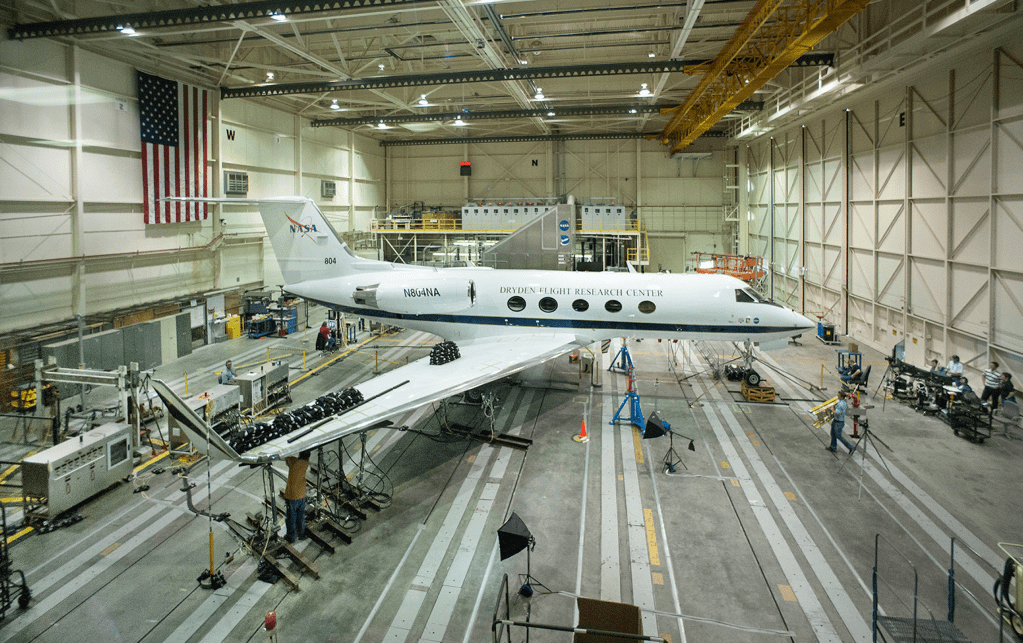

The Flight Loads Laboratory (FLL) was constructed at NASA’s Dryden Flight Research Center in 1964 as a unique national laboratory to support flight research and aircraft structures testing. FLL personnel conduct mechanical-load and thermal tests of structural components and complete flight vehicles in addition to performing calibration tests of vehicle instrumentation for real-time determination of flight loads.

Mechanical loads and thermal conditions can be applied either separately or simultaneously to simulate combined thermal-mechanical load conditions. FLL personnel also conduct modal survey and structural mode interaction testing to support structures research and assess aircraft for flutter airworthiness.

Read Flight Loads Laboratory Fact Sheet

Aerostructures Branch Fact Sheet

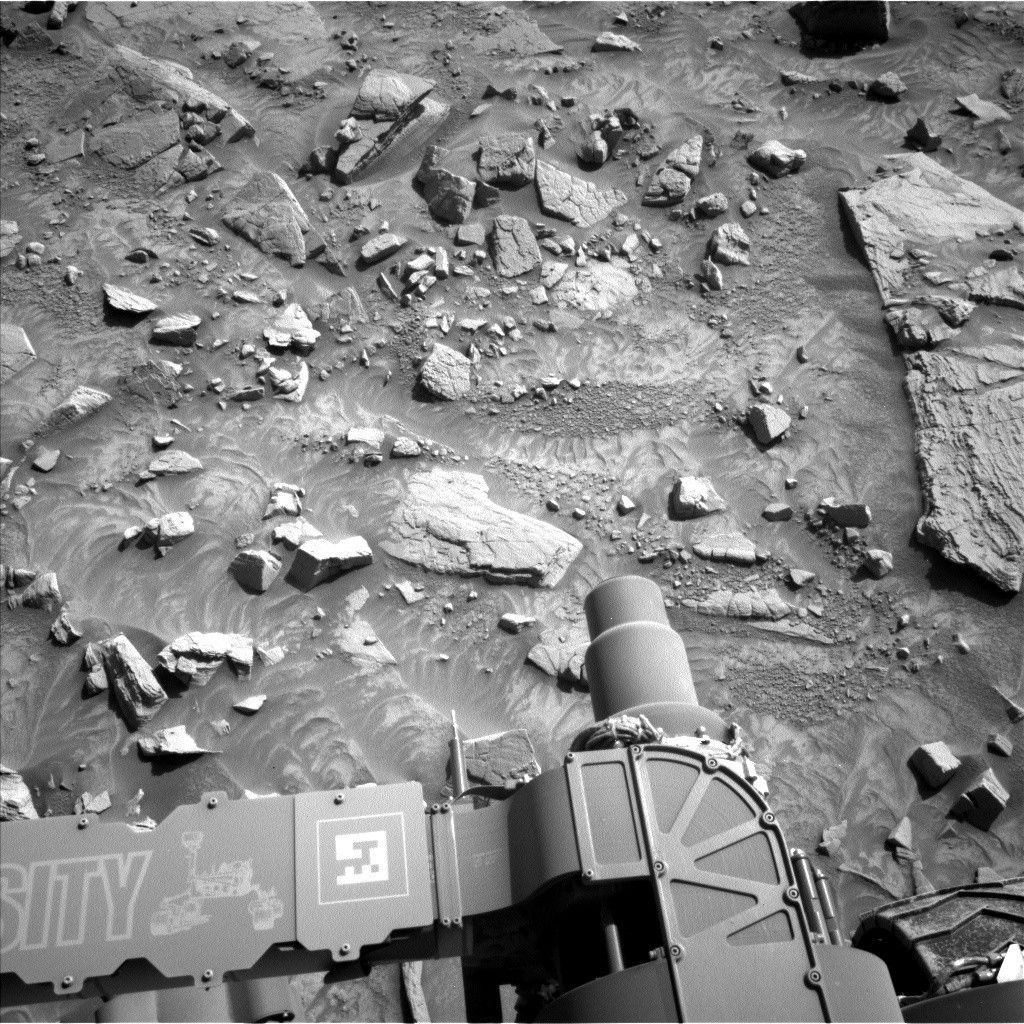

The Aero/Structural Loads Group within the Aerostructures Branch at the NASA Armstrong Flight Research Center (AFRC) performs structural research, analysis, and testing to ensure structural airworthiness in order to safely achieve the mission success objectives of flight research projects at AFRC.

The group achieves these objectives by providing flight- and ground-testing technical

support throughout a project’s lifecycle. This support includes structural design; stress and loads evaluation; test planning; test execution; and post-test data analysis and documentation. Expertise in aircraft structural and loads analyses combined with extensive experience in both commercial and military aircraft renders the Aero/Structural Loads Group well equipped to provide technical services in aircraft testing.

Flight Research Facilities

The Flight Demonstrations Capabilities (FDC) project validates benefits associated with critical technologies through focused flight experiments.

Through the integration of appropriate flight test capabilities and assets – whether from NASA, other government agencies or industry – FDC campaigns focus on aggressive, success-oriented schedules using the best collection of assets. The FDC project supports tests of technology at all phases of maturation.

Read About NASA Flight Research Facilities