One of the aeronautical challenges of the 21st century is finding a way to quickly construct new, sustainable aircraft. Hi-Rate Composite Aircraft Manufacturing (HiCAM), one of NASA’s newest projects, is tasked with addressing that challenge.

HiCAM is researching how to manufacture large aircraft components, like aircraft wings and fuselages, from composite materials at a higher rate of speed – comparable to that of aircraft made from metallic materials.

“HiCAM is enabling widespread use of composite materials to be applied in the next generation of aircraft. In order to do that, we need to create construction systems that produce aircraft quickly and at a competitive cost,” said Rick Young, HiCAM’s project manager, based at NASA’s Langley Research Center in Virginia.

Sustainable Aviation Fleet

HiCAM is taking place as part of the Sustainable Flight National Partnership (SFNP), through which NASA and its partners in industry, academia, and government are working to make aviation more sustainable using green technologies.

By building more aircraft components out of composites – which can be a custom-tailored mixture of materials like plastics, graphite, and ceramics – an aircraft’s weight can be substantially reduced, making it more fuel-efficient.

But how do composites make these innovative designs possible?

“A great analogy to how composites work is a sheet of plywood,” Young said. “It has many layers of wood, and the grain of each layer runs in a different direction. These layers are stacked up and glued, making plywood. Putting layers in different directions keeps each layer of wood from splitting along the grain, making it stronger.”

Composites have layers of fiber-reinforced materials, usually plastic. These layers are very thin – the thickness of a sheet of paper – and made of stiff, lightweight graphite fibers 10 times smaller than a human hair. Each layer runs in a different direction, and when stacked together and hardened, they form a stiff structure that is not easily broken.

Therefore, composites can be even stronger and lighter than the metals that are currently used in aircraft construction. This quality also allows aircraft designers to be more creative in coming up with innovative aerodynamic shapes that can help cut down on fuel usage.

New Ambitions, New Project

During the next 20 years, the worldwide commercial aviation fleet will need about an estimated 40,000 new aircraft to meet the growing demand for air travel and replace aging airliners.

The retirement of older aircraft, combined with anticipated growth in the demand for air travel, translates into replacing most of the current global fleet and doubling its size. Most of these new aircraft will be needed in the single-aisle market.

“Right now, single-aisle airliners like the Boeing 737 are constructed at a rate of about 60 aircraft per month, and they are made from metallic structures. Aircraft that already use composites, like the Airbus A220 or the larger Boeing 787 Dreamliner, are produced at a rate of no more than 14 per month,” Young said.

HiCAM’s goal is to accelerate this process, aiming for the capability of constructing 80 aircraft per month using composite materials. To achieve this, researchers are investigating which composite materials and construction methods can best be accelerated to this high rate of production.

“Much of what we’re doing is taking composites production to the next level. We’re taking methods that have already been proven and figuring out how to do it faster. Increasing the production rate can significantly reduce the cost of composite structures, which is needed to compete internationally,” Young said.

The production rate is limited by the time it takes to fabricate the parts, assemble them to make large aircraft components, and inspect the results for quality.

Most aircraft components currently made from composites are thermosets, which work similarly to two-part epoxies used around the house. When the two materials mix and are heated, a chemical reaction occurs that combine them into a solid, rigid object. The process is irreversible, and the two materials cannot be separated again.

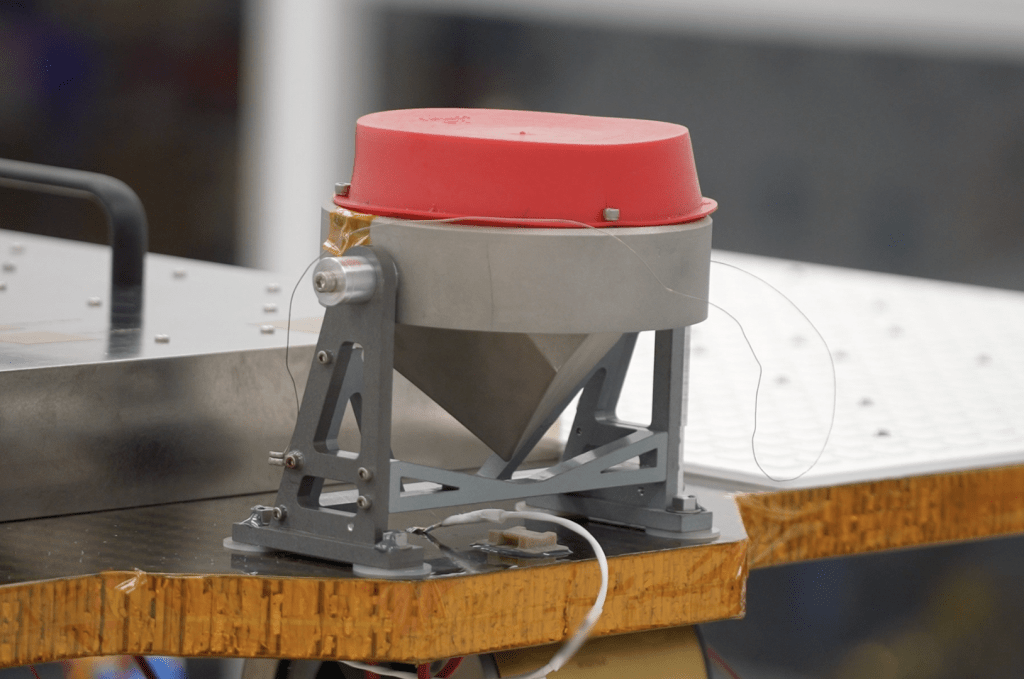

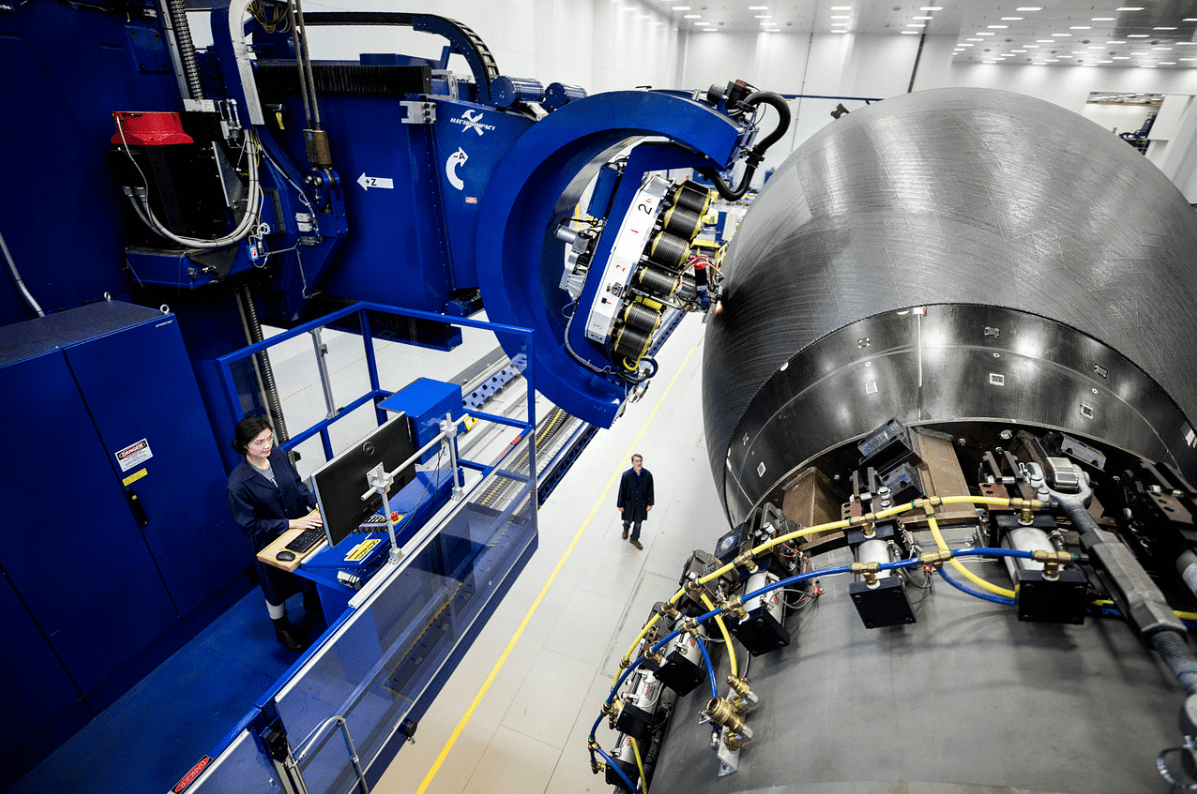

For each part, the raw composite materials are placed layer-by-layer into a mold. The flexible content of the mold is turned solid by curing it under high heat and pressure in a huge oven called an autoclave.

Altogether, this is a long process, with materials placed into the mold, prepared for the autoclave, cured inside the autoclave for up to eight hours, cooled, and assembled into finished components – not to mention all the inspections required throughout the process.

Finding the Right Stuff

Central to HiCAM’s work is examining which composite materials cure fastest in the autoclave, which could be cured without using an autoclave, and whether there are additional composites that could be adopted into aircraft construction.

For example, the project is considering the idea of using thermoplastic materials. As opposed to thermosets, thermoplastics are similar to a glue stick or hot glue. When heated, they melt into liquid. When cooled, they become solid in whatever new shape has been created.

“Thermoplastics don’t require the long eight-hour baking process that thermosets do. They have been widely used in aircraft interiors, overhead storage bins for example, but they have never been used in the aircraft manufacturing industry for larger components like the wings or fuselage,” Young said.

In addition to thermoplastics, HiCAM also is researching the use of new resins to reduce cure time to minutes instead of hours – or even eliminating the need for an autoclave at all.

Another way HiCAM is looking to accelerate the production rate is reducing assembly time. Currently, aircraft components made from composites are made in smaller pieces and put together using thousands of fasteners. One solution HiCAM is working on is “stitching” composite parts together before they are cured – effectively fabricating one large composite component that doesn’t require fasteners.

Other time-consuming steps in the production process are when humans perform certain tasks such as inspections. Sometimes, this can slow down the entire assembly line, especially if a component is found to have defects.

To resolve these delays, HiCAM is researching ways to involve more automation for tasks like inspections, which would speed things up. Also being looked at is in-situ inspection, or inspection during the manufacturing process itself.

Industry Implementation

HiCAM is working together with industry partners in the Advanced Composites Consortium on the development of these high-rate composite manufacturing processes. Industry partners include aircraft manufacturers, equipment and software developers, and material suppliers.

“The technology we’re pursuing is intended for new transport aircraft entering service in the early 2030s,” Young said. “HiCAM’s goal is to prove that this construction rate can be achieved for composites by 2026, then transfer the technology to the aviation industry so they can implement it in a new aircraft production program.”

While HiCAM’s focus is on transport aircraft, Young notes the potential for other applications of the technology, including small aircraft structures for Advanced Air Mobility.