The future of commercial flight is sustainable, efficient, and cleaner. To make this vision a reality, NASA established the Sustainable Flight National Partnership to bring advanced, high-risk, high-reward technologies to market to help combat climate change, reduce costs, and promote American leadership in aviation.

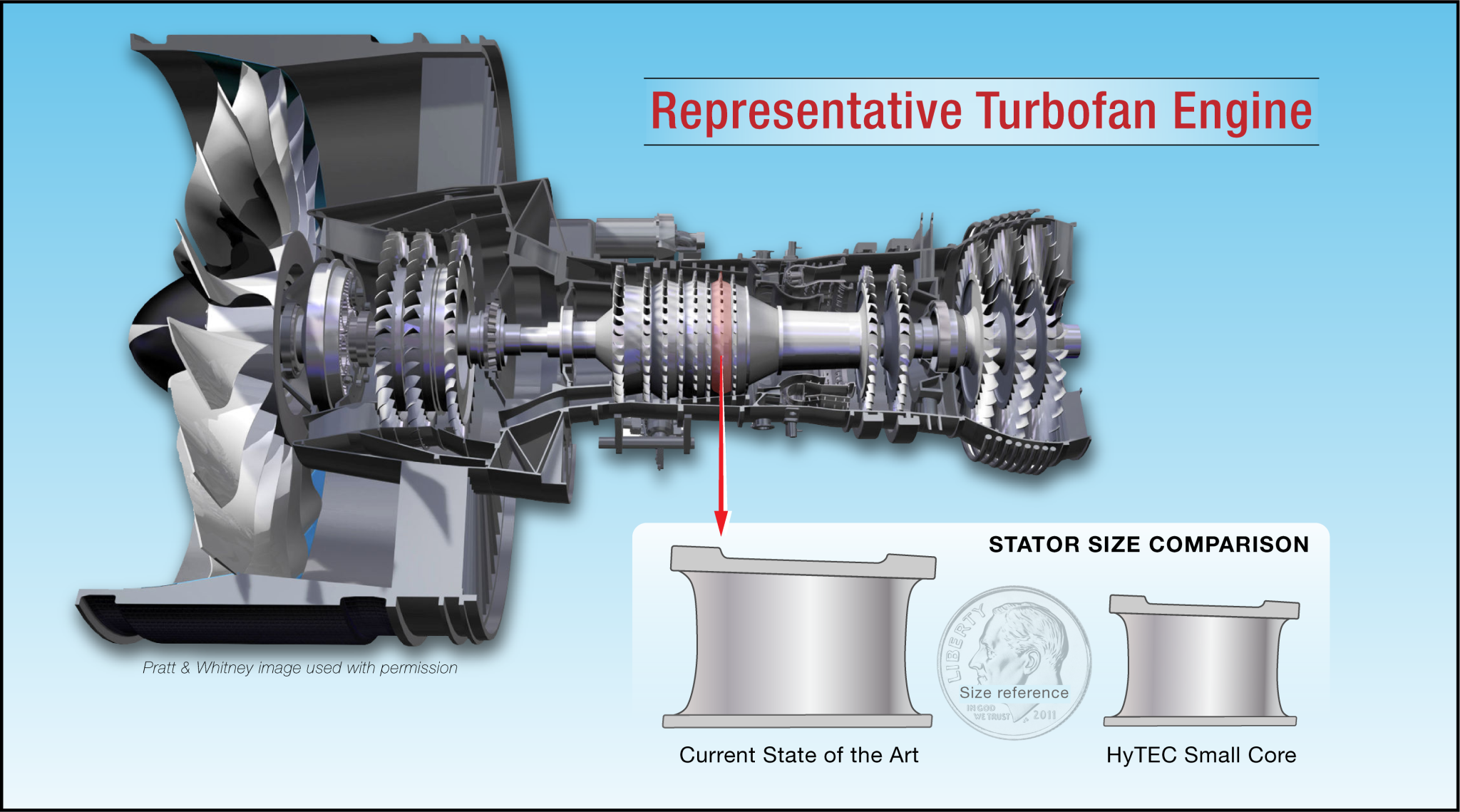

The agency is now working to develop highly efficient engines for future single-aisle commercial aircraft under its Hybrid Thermally Efficient Core (HyTEC) project at NASA’s Glenn Research Center. The HyTEC team recently awarded six cost-share contracts with GE Aviation of Cincinnati, Ohio, and Pratt & Whitney of Hartford, Connecticut, with a maximum combined value of $18.8 million. Both GE and Pratt & Whitney will match or exceed NASA’s investment during the contract period.

Under these contracts, GE Aviation and Pratt & Whitney will help NASA address specific technical challenges associated with reducing engine core size, including:

- Advanced high-pressure compressor

- Develop casing treatments and advanced designs with smaller parts and tighter clearances to enable small core compressors that maintain operability while optimizing performance and efficiency.

- Advanced high-pressure turbine aerodynamics

- Enable more efficient turbine operation by developing advanced blade and cooling designs and aerodynamic features.

- Enhanced combustor materials

- Develop ceramic matrix composite (CMC) liners for combustors to increase performance and durability.

- High-temperature turbine materials

- Develop CMCs and environmental barrier coatings (EBCs) for turbine blades and vanes to increase temperatures and efficiency of turbines.

NASA believes evolving and shrinking an aircraft engine’s core will reduce fuel burn by 5-10%, creating a parallel reduction in emissions. These smaller engine cores also could produce about four times more power to be extracted from the engine. Increasing available energy is extremely important because future hybrid- and- turbo-electric aircraft will require tremendous amounts of power.

“These partnerships represent NASA’s commitment to quickly developing and advancing the small core technologies needed to usher in sustainable flight,” said Tony Nerone, HyTEC’s project manager at Glenn. “By collaborating with industry over the next two years, we’ll leverage their unique capabilities, investments, and knowledge to develop engines that produce more electric power, are more durable, and perform the same or better than today’s turbofan engines while burning less fuel.”

The work and testing completed across the agency and the two companies under these contracts are just the beginning. NASA expects to be ready for ground demonstrations of small core engines by 2026. In the meantime, the agency and its partners will use an Electric Powertrain Flight Demonstration aircraft and the NASA Electric Aircraft Testbed to further develop components and validate the many benefits of electric flight before these technologies are ready for your next commercial flight.

Jimi Russell

NASA’s Glenn Research Center