In This Week’s Star

- SLS Core Stage Production Continues for Rocket’s First Flight

- Redstone Arsenal Gate 9 Closure June 30-July 5

- NASA Teams with Italian Space Agency to Probe Cosmic X-ray Mysteries

- Essential to the Mission: Cynthia Vemmer

- Marshall Hosts ‘Take Our Children to Work Day’ June 22

- This Week in NASA History: U.S. Microgravity Laboratory Launches — June 25, 1992

- Obituaries

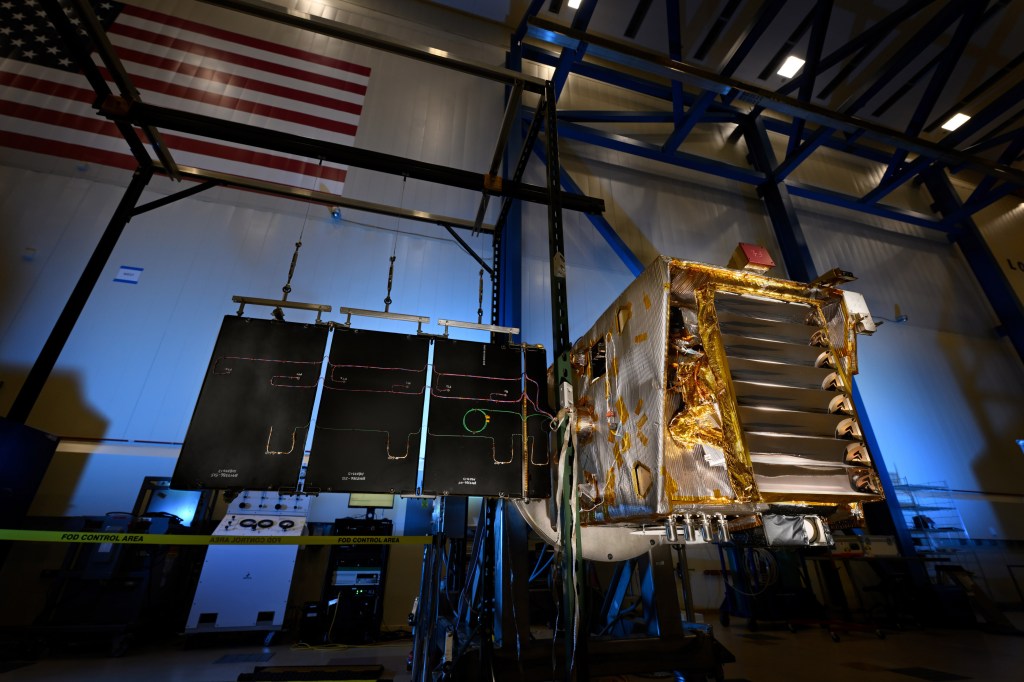

SLS Core Stage Production Continues for Rocket’s First Flight

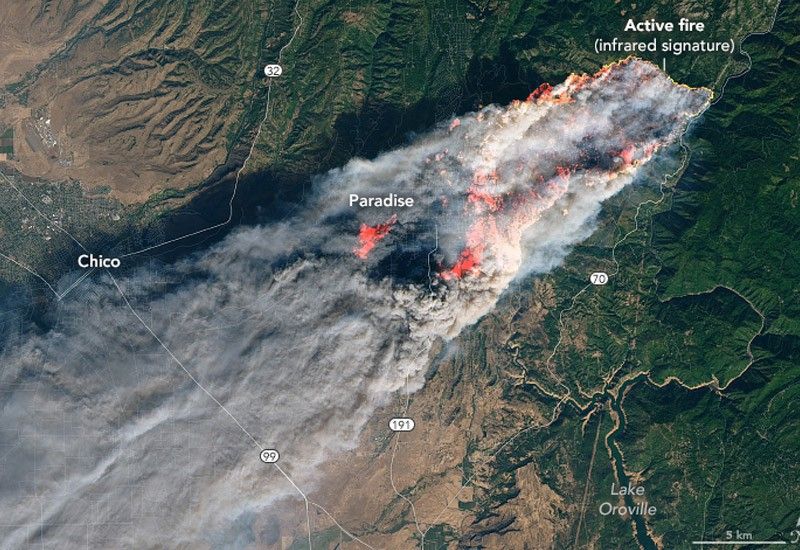

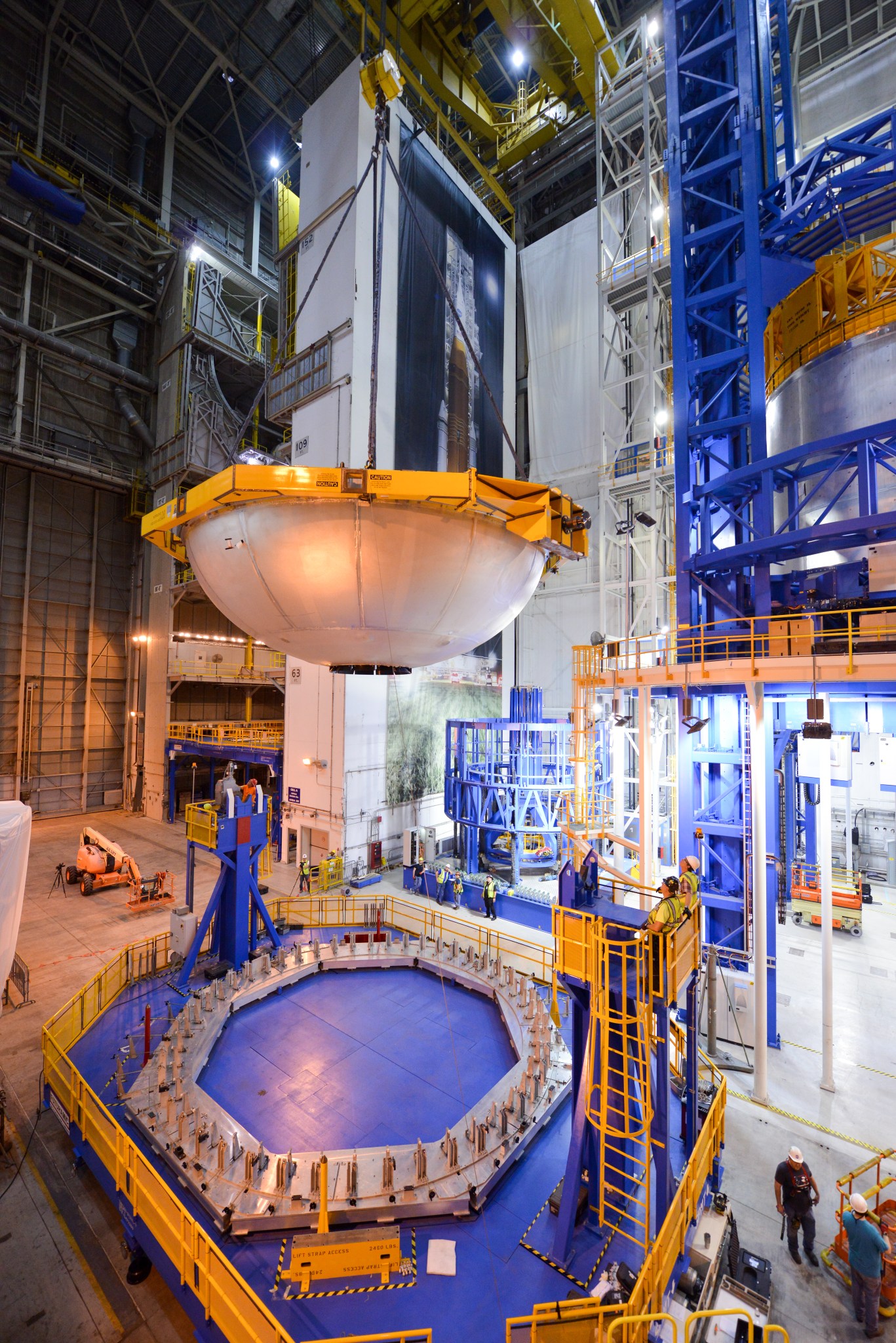

Throughout NASA’s Michoud Assembly Facility — the agency’s 43-acre rocket factory — production continues on all five parts of the Space Launch System’s core stage. Major structural manufacturing is complete on three parts — the forward skirt, intertank and engine section — for the rocket’s first integrated flight with NASA’s Orion spacecraft. And test articles — structurally similar to flight hardware and are used to qualify the core stage for flight — are in various stages of production and testing.

“One of the most challenging parts of building the world’s most powerful rocket has been making the largest rocket stage ever manufactured for the first time,” said Steve Doering, SLS stages manager at NASA’s Marshall Space Flight Center. “The 212-foot-tall core stage is a new design made with innovative welding tools and techniques.”

To build the rocket’s fuel tanks, Boeing — the SLS core stage prime contractor — is joining some of the thickest parts ever built with self-reacting friction stir welding. NASA and Boeing engineers and materials scientists have scrutinized the weld confidence articles and developed new weld parameters for the liquid oxygen and hydrogen tanks for the first SLS mission.

Manufacturing is expected to resume soon at Michoud’s Vertical Assembly Center, where core stage parts are welded. NASA halted production in early May after a liquid oxygen tank dome was inadvertently damaged during pre-weld preparations on the infeeder tool — the tool used to position the large dome for welding.

While the mishap investigation is wrapping up, NASA and Boeing have fully inspected the dome and found that while the hardware sustained minor damage, it is usable for its original purpose as part of a structural test article. Repairs to the infeeder tool, which also sustained some damage, are complete. Welding is resuming to finish construction of the liquid oxygen test article, and upon completion, the tank will undergo inspection for any flaws, final processing and proof testing.

In another area of the factory, domes and segments for the flight liquid oxygen tank await their turn to be joined on the Vertical Assembly Center, and Boeing is completing welding domes and segments that will make up the flight liquid hydrogen tank.

Recently, major structural construction was completed on the flight intertank — the one part of the core stage structure that is not welded. With walls too thick to be welded, the intertank’s eight panels are connected with 7,500 bolts. The walls have to be extremely strong because of the force it feels from the solid rocket boosters attached to it. To complete assembly on the inside of the core stage, the team is outfitting the intertank, flight forward skirt and engine section with avionics, wire harnesses, tubing, sensors and propulsion systems.

The first structural test article for SLS, an engine section which is similar to the flight article located at the bottom of the rocket’s core stage, is being installed on a test stand at Marshall. Hydraulic cylinders will push, pull, twist and bend the engine test article to validate the design and ensure it can withstand the pressure expected during launch and ascent.

“We are conducting the largest NASA launch vehicle test campaign since space shuttle development,” said John Honeycutt, SLS program manager at Marshall. “The team is focused on delivering hardware to the pad for the first launch. We just completed integrated structural testing for the stage that will send Orion out beyond the moon on the first flight. Now, we’ll be putting the core stage parts through the paces to gain an in-depth understanding of the rocket we are building for the first time as we expose parts of it to the extreme conditions of spaceflight.”

Redstone Arsenal Gate 9 Closure June 30-July 5

Redstone Arsenal Gate 9 at Rideout Road construction is nearing completion. To allow for the movement of equipment and structures to the new gate location, Gate 9 inbound will close at 2 p.m. June 30, and remain closed until 5 a.m. July 5. Gate 9 outbound will close at 6 a.m. July 1, and will reopen at 6 a.m. July 2.

During the July 1-2 closure of Gate 9 inbound and outbound lanes, Gate 8 at Goss Road will be the 24/7 access gate, and Gate 7 at Martin and Zierdt roads will operate from 5:30 a.m. to 8 p.m.

Gate 9 will reopen for inbound traffic on July 5. To reach the new operational gate, motorists should proceed slowly through the older gate which will not be staffed. They will then proceed to the new gate at which time they will undergo the normal gate operating procedures. Motorists merging onto Toftoy Road should use the two left lanes when entering Gate 9 to eliminate having to merge across several lanes of traffic.

The Gate 9 Visitor Control Center will remain open for normal operating hours.

Marshall team members are encouraged to travel safely and pay close attention to any traffic signals.

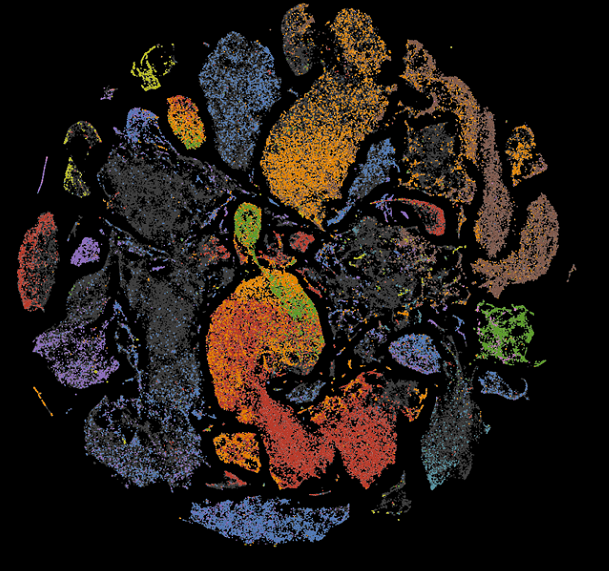

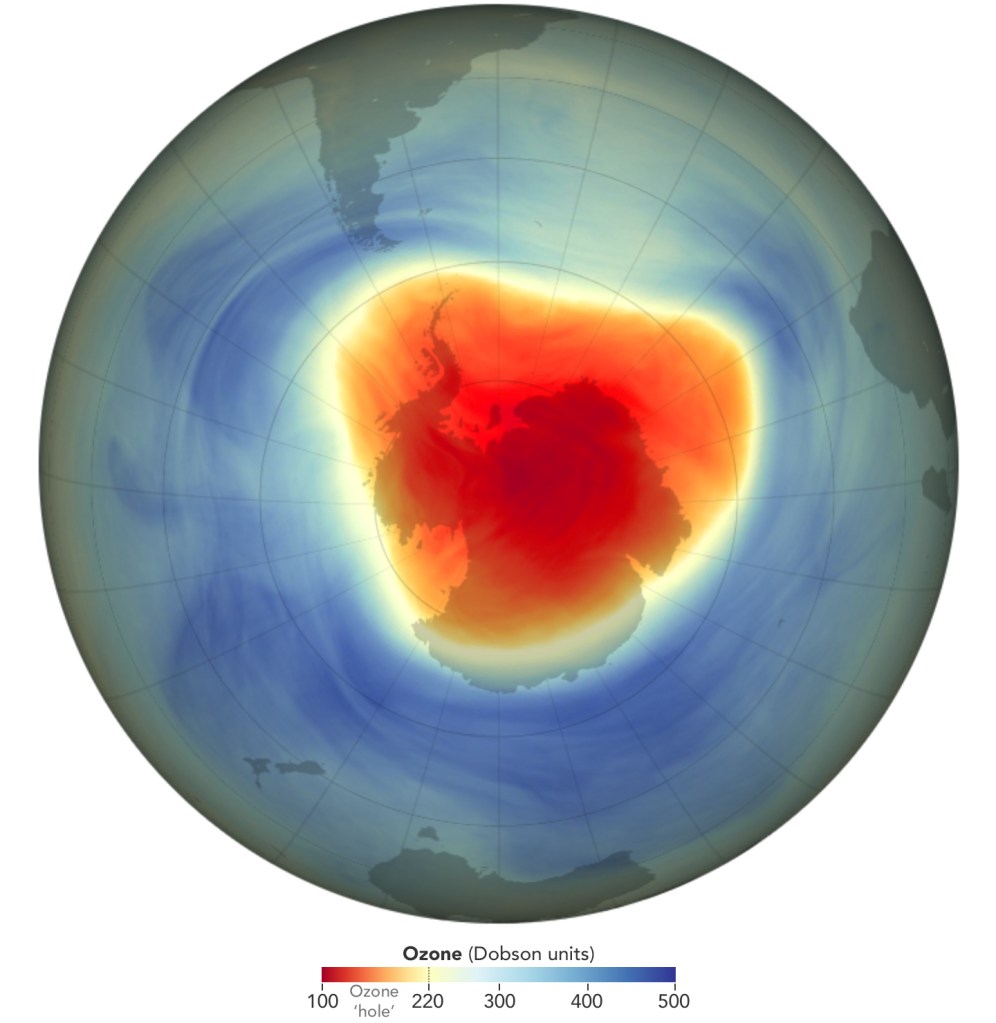

NASA Teams with Italian Space Agency to Probe Cosmic X-ray Mysteries

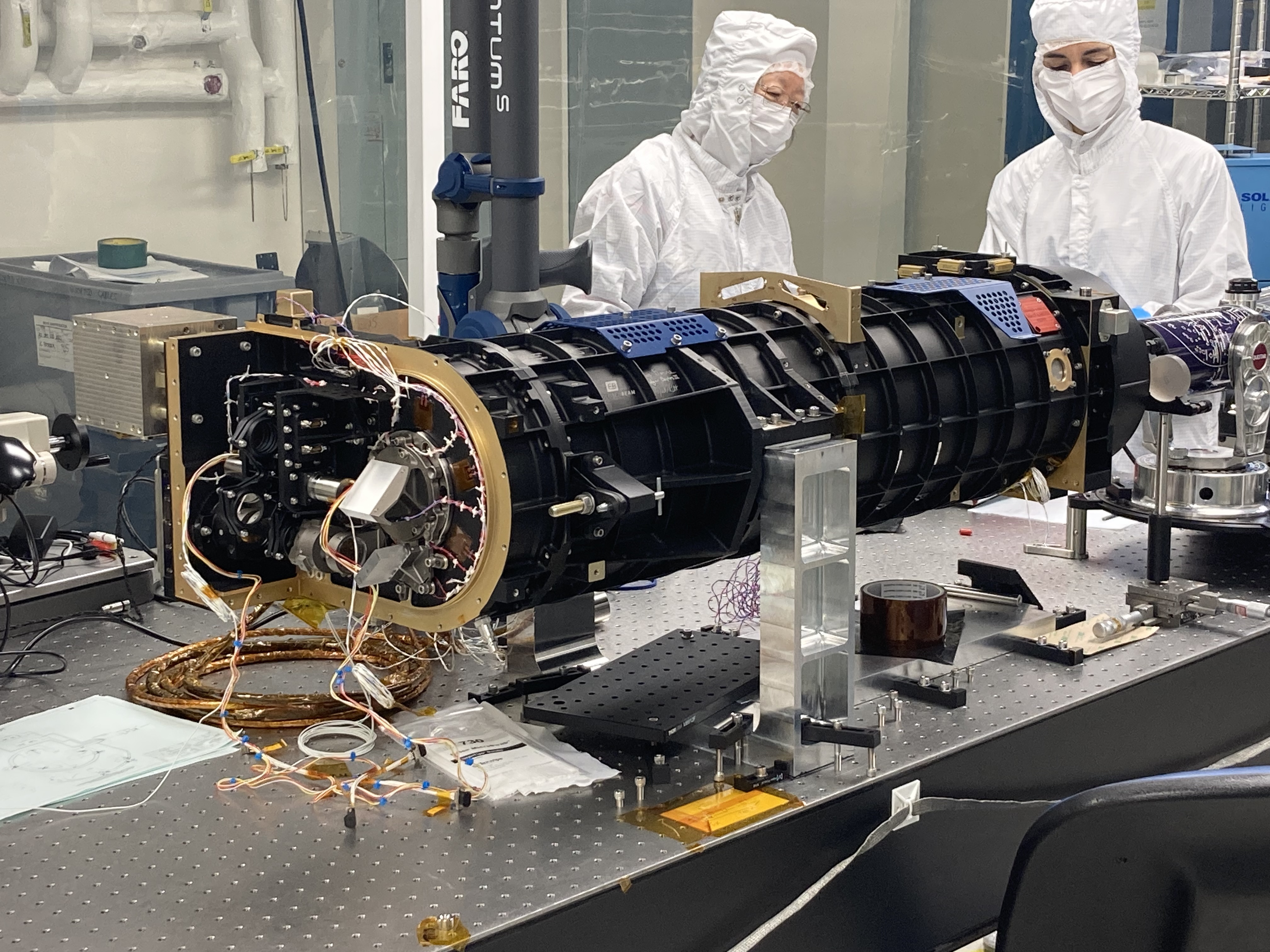

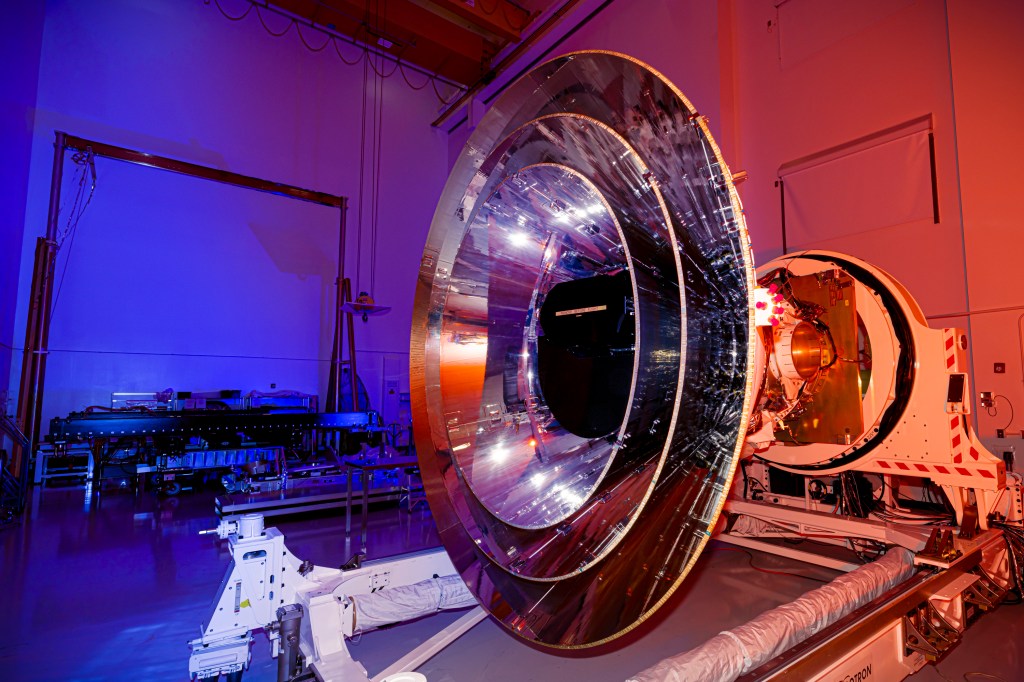

A new partnership forged between NASA and Italy’s space agency paves the way for a breakthrough mission to explore some of the most turbulent and extreme environments in our universe.

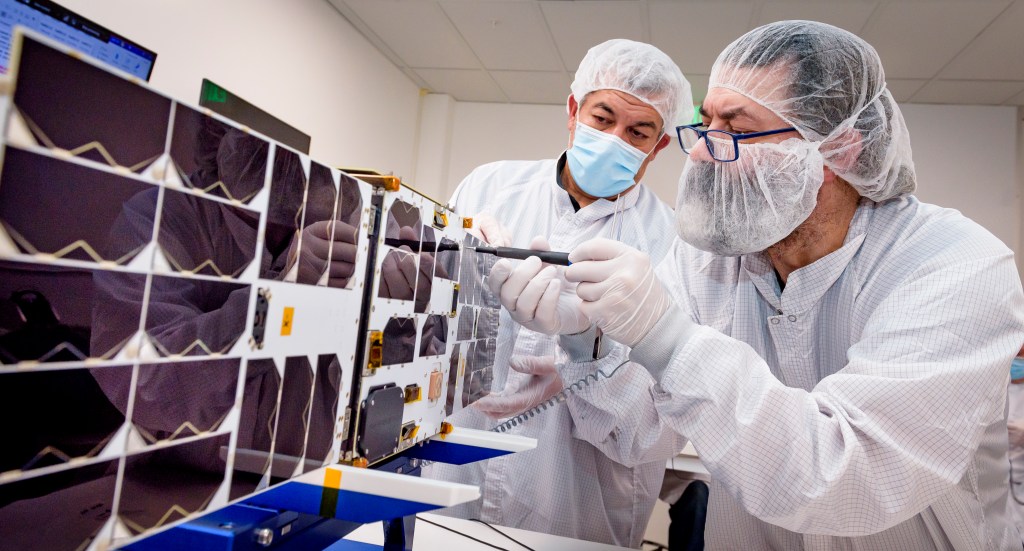

Robert Lightfoot, NASA’s acting administrator, signed an agreement June 20 with Roberto Battiston, president of the Italian Space Agency, defining the terms of cooperation for the Imaging X-ray Polarimetry Explorer mission during a ceremony at the Paris Air Show in Le Bourget, France.

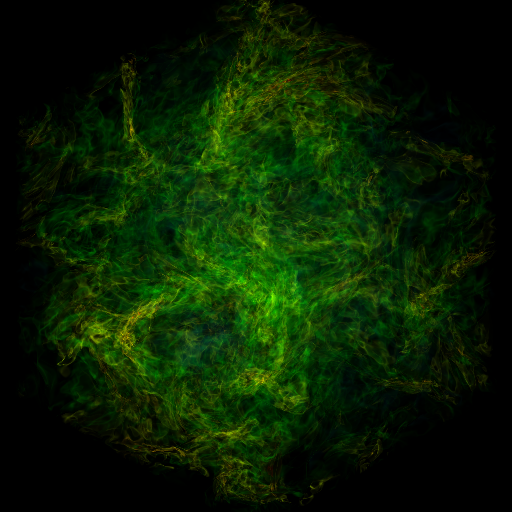

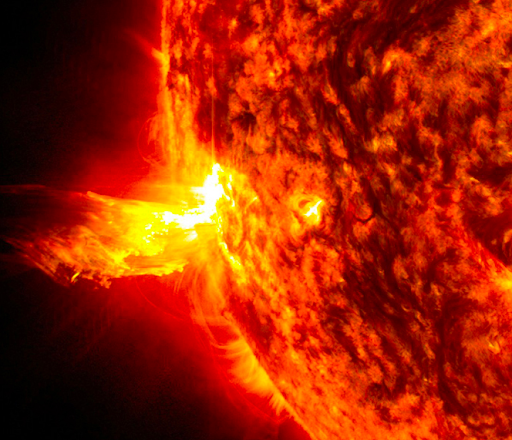

From the hottest, messiest star factories to violent jets screaming away from monster black holes, IXPE is next in the line of Small Explorer missions. NASA’s Marshall Space Flight Center leads the mission for the agency’s Science Mission Directorate while NASA’s Goddard Space Flight Center manages the Explorers Program.

“NASA welcomes the opportunity to work with the Italian Space Agency on this mission, to build upon a history of strong cooperation between our agencies in the space sciences,” said Lightfoot. “We wish all those working on IXPE great success in the years ahead, and we eagerly anticipate the scientific promise of this exciting space science mission.”

The IXPE mission, slated to launch in 2020, will fly three telescope systems capable of measuring the polarization of X-rays emitted by cosmic sources. By taking advantage of polarization as a tool for exploration, IXPE will provide important clues about the origins of cosmic X-rays and their interactions with matter and gravity as they travel through space.

“With this agreement Italy confirms to play a leading role in the scientific field of high energy studies,” said Battiston. “The development of IXPE is the result of the great teamwork of the Italian Space Agency, of the National Institute of Astrophysics, National Institute of Nuclear Physics, Roma 3 University and more in general of the entire Italian aerospace sector. This cooperation with NASA is the demonstration of the high standard of our work.”

The Italian Space Agency will contribute IXPE’s sophisticated “eyes” — three polarization-sensitive X-ray detectors, which were developed in Italy — and the use of its equatorial ground station at Malindi, Kenya. NASA will supply the X-ray telescopes and use of its facilities to perform end-to-end X-ray calibration and science operations.

Ball Aerospace in Broomfield, Colorado, will provide the spacecraft and mission integration. Ball Aerospace will also operate the flight system with support from the Laboratory for Atmospheric and Space Physics at the University of Colorado at Boulder.

Other partners include Stanford University in Palo Alto, California; McGill University in Montreal, Canada; and the Massachusetts Institute of Technology in Cambridge.

Essential to the Mission: Cynthia Vemmer

Cynthia Vemmer began her NASA career in 1998 as a management support assistant for the Environmental Control and Life Support Systems team at NASA’s Marshall Space Flight Center.

After several extended temporary assignments, including four to NASA Headquarters, Vemmer now serves as a financial program specialist at Marshall. She is responsible for supporting and approving travel requirements for all extended temporary duty assignments in Marshall’s Office of the Chief Financial Officer.

“I have been very fortunate to serve in several departments at Marshall and NASA Headquarters,” said Vemmer. “These experiences have given me the perspective of the travelers that I support now through the CFO’s office.”

The CFO office has many different functions — from auditing to allocations to projections. Particularly, handling travel in the Accounting Operations Office, Vemmer and her teammates work to ensure that Marshall employees get from destination to destination in accordance with federal travel regulations to further NASA’s space exploration mission.

“One of the things I like about working in the travel group is the structure,” said Vemmer. “I know people can get frustrated by all of the rules and regulations, but I like that because it gives you detailed parameters for getting things done. If I don’t do my job to make sure we are meeting those standards, then it makes it more difficult for travelers to do their job.”

While Vemmer may not work on rocket engines or other hardware, her service in various support organizations has connected her in a unique way to the heart of NASA’s mission.

“When I came to work for NASA, I really liked the idea of being connected to something bigger than myself,” said Vemmer. “While working in ECLSS, I was able to learn how the water generation unit works on the International Space Station. When I worked for the Office of Exploration Systems at headquarters, I enjoyed the idea of going to Mars and dreaming of how we could get there. I have never worked with space hardware, but I have always known that my job has value no matter what organization I’ve been a part of.”

Click here to learn more about Vemmer and watch a video highlight of her NASA career.

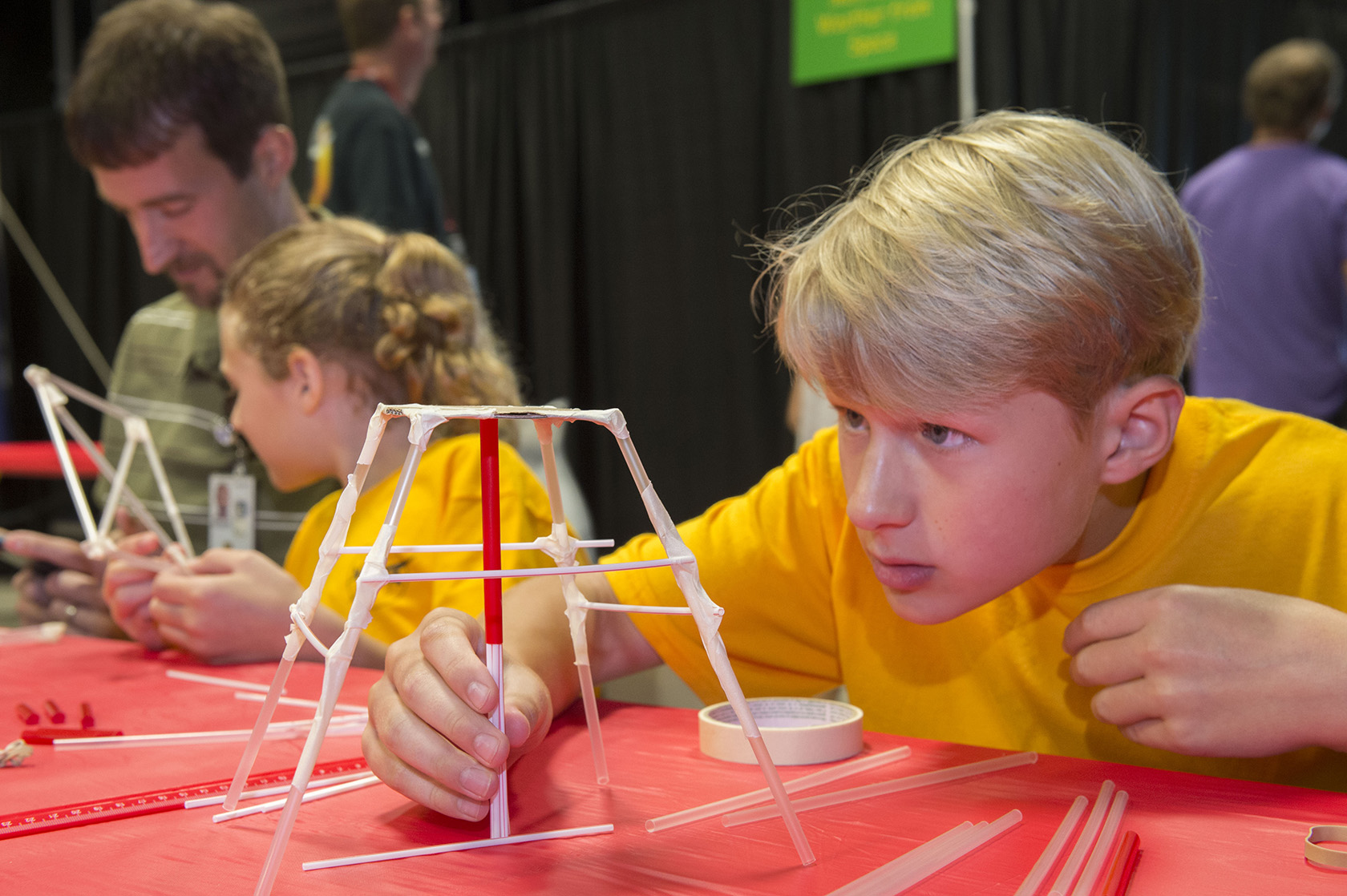

Marshall Hosts ‘Take Our Children to Work Day’ June 22

David Burns, center, manager of the Science and Technology Office at NASA’s Marshall Space Flight Center, welcomes children to Marshall’s “Take Our Children to Work Day” event June 22. Burns and event organizers kicked off the day’s activities in Building 4316, and dozens of Marshall team members volunteered their time and expertise to lead tours and demonstrations and show off Marshall’s work. The yearly event is organized by Marshall’s Office of Diversity and Equal Opportunity. (NASA/MSFC/Emmett Given)

Nate Maehlmann, right, and his sister Clara build scale-model launch platforms with help from their father, Rick Maehlmann, left, a lead aerospace engineer in Marshall’s Propulsion Systems Department. Throughout the day, participating kids toured key Marshall facilities, watched science, propulsion and engineering demonstrations, and made a variety of NASA-themed crafts. (NASA/MSFC/Emmett Given)

Selah McElroy, front, and her older sister Jada, daughters of Marshall environmental engineer Malene McElroy, greet Oscar the Robot during Marshall’s “Take Our Children to Work Day” activities. Oscar and his partner, Jack Prather, president of Pro-Bots Promotional Robots in Lawrenceville, Georgia, are frequent participants in the event. (NASA/MSFC/Emmett Given)

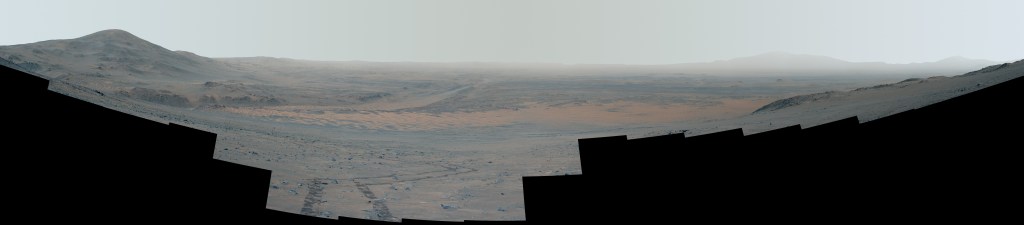

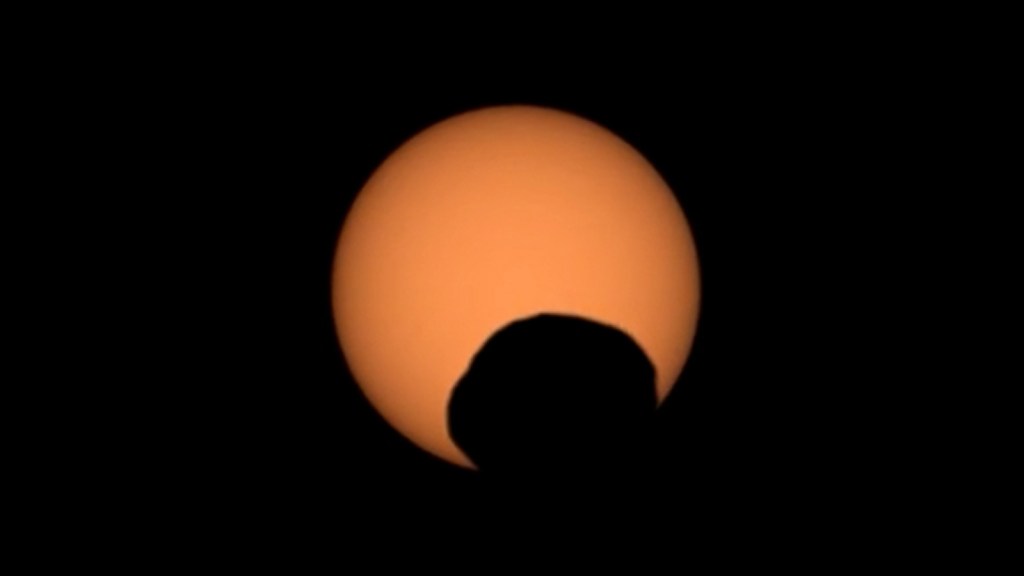

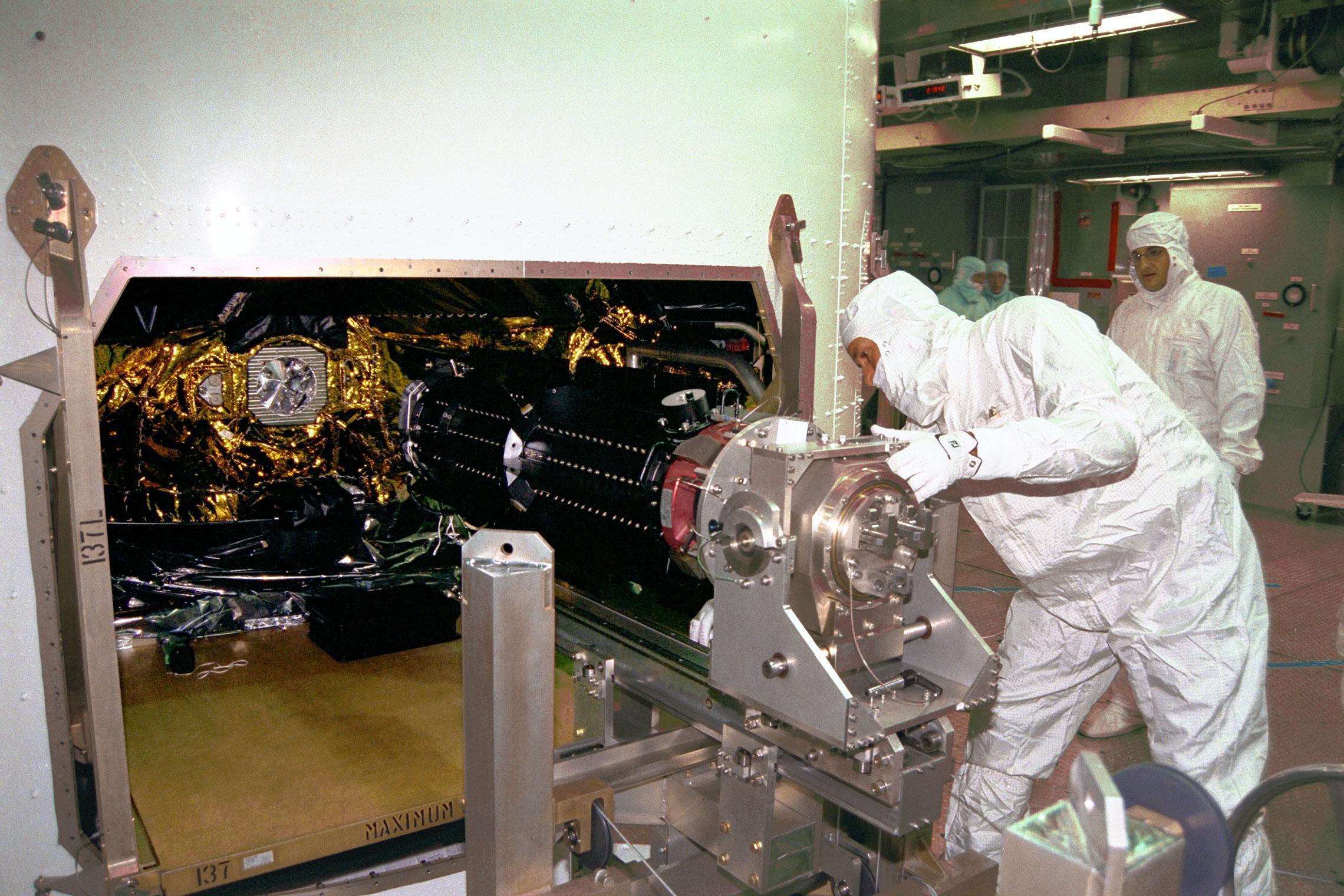

This Week in NASA History: U.S. Microgravity Laboratory Launches — June 25, 1992

This week in 1992, space shuttle Columbia and STS-50 launched from NASA’s Kennedy Space Center, carrying the first United States Microgravity Laboratory. The Spacelab long module included an Extended Duration Orbiter pallet and consisted of 31 experiments ranging from the manufacture of crystals for possible semiconductor use to the study of behavior of weightless fluids. USML-1 was a national effort to advance microgravity research in a broad number of disciplines. NASA’s Marshall Space Flight Center managed the Spacelab program for NASA. Today, the Payload Operations Integration Center at Marshall serves as “science central” for the International Space Station, working 24/7, 365 days a year in support of the orbiting laboratory’s scientific experiments. The NASA History Program is responsible for generating, disseminating, and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological, and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)

Obituaries

Ralph E. Young, 65, of Harvest, Alabama, died June 21. He retired from the Marshall Center in 2014 as an aerospace engineer.

Thomas T. Boddie, 95, of Harvest, Alabama, died June 22. He retired from the Marshall Center in 1979 as an aerospace engineer.