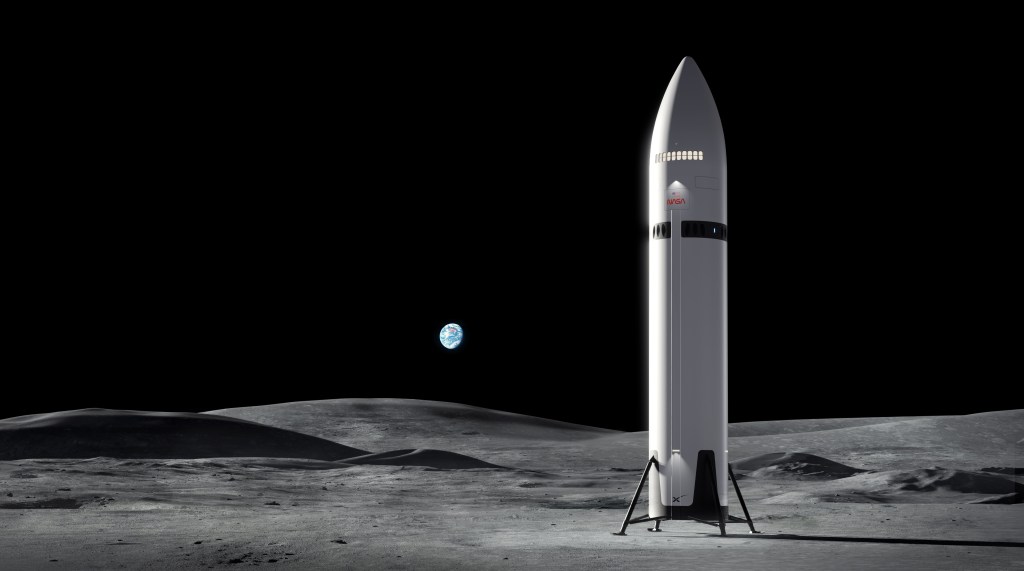

NASA Prepares for Next Artemis I Wet Dress Rehearsal Attempt

Teams are preparing for the next attempt at the Artemis I wet dress rehearsal at NASA’s Kennedy Space Center, pending range availability and restoration of propellants and gases during the test. Through the past two test runs April 3 and 4, engineers accomplished several test objectives that will prepare the teams and integrated systems for launch:

- Configuring Launch Pad 39B and the mobile launcher for the test, just as it will have to be prepared for launch

- Clearing personnel and equipment from the launch pad after configuration in order to proceed with propellant loading

- Powering up the Orion spacecraft and Space Launch System (SLS) rocket systems in launch configuration, including the solid rocket boosters, the core stage, and the Interim Cryogenic Propulsion Stage

- Checking out and verifying the Orion spacecraft countdown and commanding by flight controllers at NASA Johnson Space Flight

- Checking out the guidance, navigation and control system, and all the integrated software that operates across the rocket, Orion, ground systems, and ground support centers, including the Launch Control Center

- Verifying and checking out all the range safety and systems with the range

- Draining the liquid oxygen and liquid hydrogen after the test

- Powering down the rocket, the spacecraft, and ground systems and putting them in a safe configuration

All these activities are necessary for a successful launch or in the event launch controllers decide not to proceed with launch if a technical or weather issue arises during or prior to the countdown. Completing these objectives will allow the team to use the next test opportunity to focus on executing the remaining objectives during dynamic operations, such as loading the cryogenic propellant and working through the launch countdown.

Inspections after the second test showed the vent valve that prohibited the team from proceeding with loading liquid hydrogen was configured physically in a closed position, which prevented it from being commanded remotely to an open position. The valve positioning has since been corrected.

Teams were also able to demonstrate their ability to work through several issues, such as severe weather, delays in getting a gaseous nitrogen supply source provided by a commercial vendor up and running, and fixing systems like fans that did not perform as expected.

The SLS rocket, Orion, and the supporting ground system elements are all in excellent condition and in a configuration that supports the next opportunity.

Listen to a replay of the latest briefing, and check the Artemis blog for an update on the targeted date for resuming wet dress rehearsal testing for the Artemis I mission.

Reminders for Team Members Returning to On-site Work

NASA’s Marshall Space Flight Center transitioned to Stage 1 of the agency’s Framework for Return to On-site Work on April 4.

Following are reminders to team members who are returning on-site for work.

Stage transition: Stage 1 allows for up to 75% occupancy. The move begins the Marshall’s Future of Work transition to the new hybrid work approach but does not mean that all team members must return on-site. Telework is still encouraged, with supervisor approval. Please talk with your supervisor regarding any questions about work schedules and specific work requirements. The center’s goal is to fulfill Marshall’s missions while providing flexibility in each team member’s work-life balance.

Redstone access. PIV badges are no longer used for entry at Redstone Arsenal gates. Motorists should instead use their driver’s license, or a lane equipped with Redstone’s new facial recognition system.

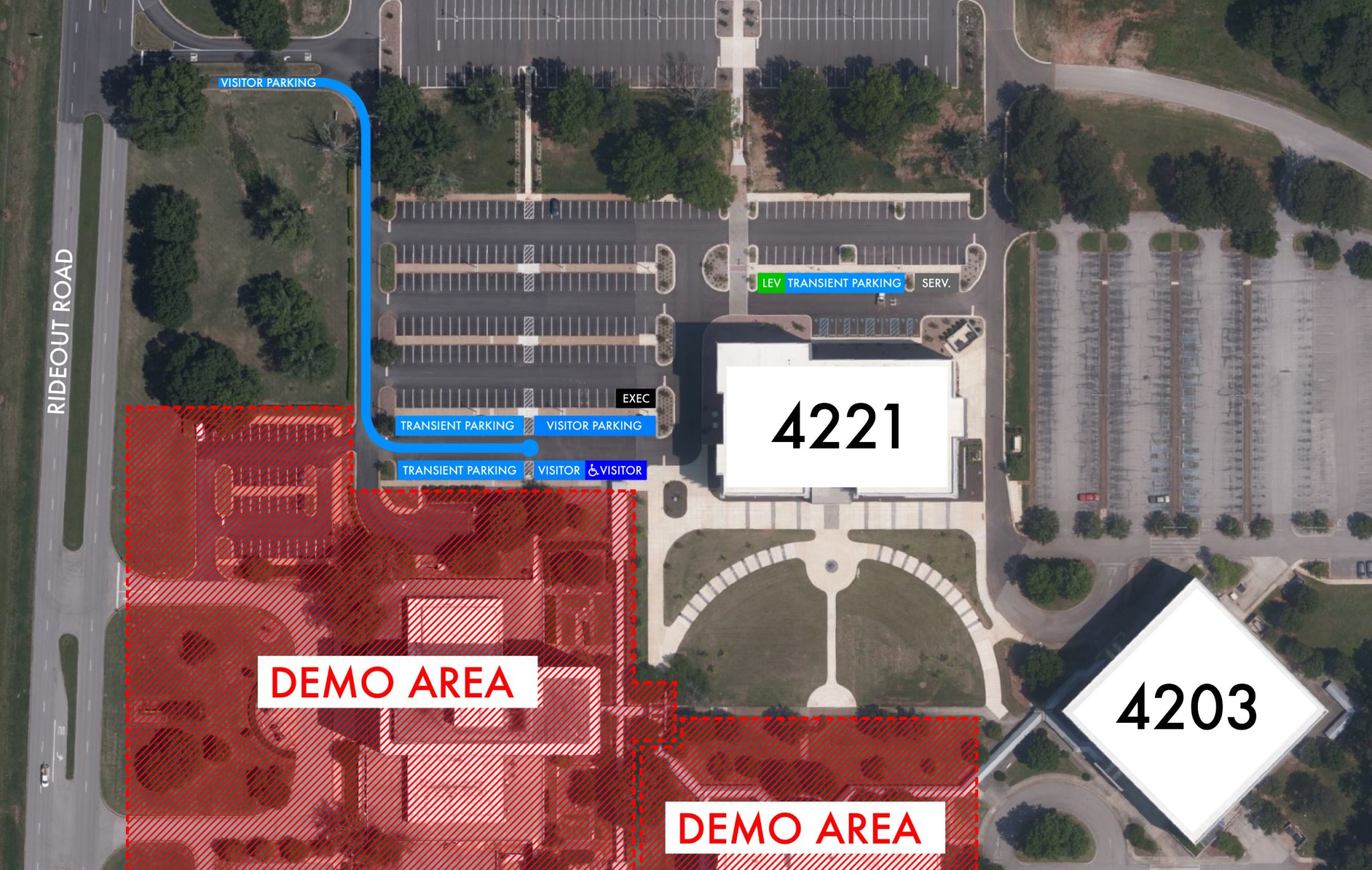

Cameras have been installed at lane 3 of Gate 1 on Martin Road East, and lanes 3 and 4 of Gate 9 on Rideout Road. These lanes are marked with the letters “SOV,” which stands for single-occupancy vehicle. Drivers carrying passengers, even if the driver is a trusted traveler, must use one of the other lanes.

Team members who onboarded before Sept. 16, 2020, have a current Alabama driver license, and currently have a NASA PIV badge, had their photos transferred into the system automatically from the Alabama Department of Motor Vehicles. Team members who onboarded on or after Sept. 16, 2020, do not have a current Alabama driver’s license, or have opted-out of the Department of Motor Vehicles transfer, should have completed their registration at Redstone’s Visitor Control Center at Gate 9 prior to Aug. 31, 2021. For more information on gate access or badging services, contact the badging office.

4221 parking: Reserved parking has been removed from the lots at Building 4221, Marshall’s new headquarters building. This will allow parking areas to be flexible and accommodate changing needs. Marshall’s Office of Center Operations will be removing and re-marking parking areas across the center, adjusting accordingly to accommodate ongoing Future of Work plans. Transient, visitor, and accessible parking areas remain at each building.

Dedicated visitor, transient, executive, accessible, and low-emission vehicle parking areas have been marked at Building 4221. Team members working in 4221 should use open parking around the building and allow transient spaces to be for non-4221 occupants.

Construction continues in the 4221/4200 area, including the parking lots and sidewalks. Crews will be working to improve accessibility in the area and team members should be cautious and be alert to changes.

Visit the Future of Work page and Return to On-Site Work FAQ on Inside Marshall and the Safer Federal Workforce site for the latest updates to health and safety protocols, site access and travel guidelines, and more.

Six Marshall Honorees Awarded Agency Distinguished Service Medals

By Rick Smith

On March 31, NASA Administrator Bill Nelson led a virtual awards ceremony honoring 48 recipients of NASA Distinguished Service Medals and Distinguished Public Service Medals – including six honorees from the agency’s Marshall Space Flight Center.

Nelson, who was joined by NASA Deputy Administrator Pam Melroy and Gregory Robinson, program director for the James Webb Space Telescope, praised award recipients for helping the agency to persevere through the challenges of the past two years.

“These individuals continued to push NASA onward and upward, to do inspiring things and inspire their fellow members of the NASA team every day,” Nelson said. “Nothing symbolizes the character of the American people like our space program.”

Marshall personnel who received the Distinguished Service Medal included:

- Dr. Paul McConnaughey, former Marshall deputy director who went on to be senior advisor to NASA’s Human Exploration and Operations Mission Directorate in Washington. He was honored for 34 years of distinguished service and leadership with a profound impact on effective NASA interagency partnerships.

- Preston Jones, former associate director, technical, at Marshall. He was recognized for 38 years of distinguished NASA service, characterized by outstanding contributions to the nation’s spaceflight, science, and exploration missions, which had a profound impact on NASA’s mission success.

- Roy Malone, former director of Marshall’s Office of Center Operations. He was honored for 38 years of distinguished service that had a profound impact on the effectiveness of NASA with other federal agencies, ensuring mission success for critical agency programs.

- Bobby Watkins, former director of the Human Exploration Development & Operations Office at Marshall. He was honored for exceptional leadership in the evolution of that office and for his management of current and future NASA programs and projects.

- Dr. Philip Stahl, the Marshall senior optical physicist who helped develop mirror technology for NASA’s James Webb Space Telescope. He was recognized for outstanding contributions to science and optical technology development, facilitating enduring U.S. and NASA leadership in space telescope design.

- David Herda, manager of Aerojet Rocketdyne’s resident management office. He was honored for more than 15 years of exemplary leadership and service to NASA in support of the Space Launch System program and the Space Shuttle Main Engine project.

The medals are NASA’s highest form of recognition for government and nongovernment workers who – through distinguished service, ability, or vision – have contributed to NASA’s advancement of the goals and interests of the nation. Individual achievements and contributions demonstrate a level of excellence with a profound or indelible impact on the agency’s mission success.

Marshall Director Jody Singer, who introduced the segment recognizing Marshall recipients, thanked honorees directly for their contributions. “You deserve all the praise and recognition these awards bring you today,” she told them. “Thank you for going above and beyond to advance NASA’s mission and uphold its core values.”

The online ceremony also included a presentation of the James Webb Space Telescope video “Look Beyond.” The Webb telescope program hosted the 2022 awards ceremony.

More information about the ceremony and awards is available here.

Smith, a Manufacturing Technical Solutions employee, supports Marshall’s Office of Strategic Analysis & Communications.

NASA, Aerojet Rocketdyne Complete Testing for Modernized RS-25 Engine

NASA completed developmental engine testing March 30 with a full-duration RS-25 hot fire, to support future engines that will launch Space Launch System (SLS) astronauts deeper into space than ever.

Operators fired RS-25 engine No. 0525 for about 8 1/2 minutes (500 seconds) and up to 111% power level on the Fred Haise Test Stand at NASA’s Stennis Space Center. The hot fire completed the fourth developmental test series and sets Aerojet Rocketdyne, lead contractor for NASA’s SLS engines, on pace to produce new RS-25s for future use.

“We’ve conducted a total of 25 tests during this remarkable development test program to modernize manufacturing, on-ramp additive manufacturing, and reduce cost of the RS-25 engines for the Space Launch System,” said Johnny Heflin, manager for the SLS Liquid Engines Office at NASA’s Marshall Space Flight Center. “These tests are helping us ensure the success of not only the upcoming flight of Artemis I but also of future missions that will lead to long-term exploration of the Moon.

NASA is building SLS to return humans, including the first woman and the first person of color, to the Moon as part of Artemis and to power future missions to Mars. Four RS-25 engines will help launch SLS missions. The first four missions, including the upcoming uncrewed Artemis I flight test to the Moon, will use modified space shuttle main engines, all of which have been tested for flight.

For future SLS missions beyond the first four, Aerojet Rocketdyne is modernizing production of new RS-25 engines, while also reducing costs by 30%. The new engines will include components manufactured with state-of-the-art fabrication techniques, such as additive manufacturing, or 3D printing. These new components have been tested during the fourth developmental series.

“As we modernize the engines, we need to ensure that they are as robust and as reliable as the original space shuttle engines,” said Jeff Zotti, Aerojet Rocketdyne RS-25 program director. “We ran the new components under the same conditions and profiles they will see during flight to ensure the engines perform as they should. This was the last step before we combine all the new, more affordable components and existing heritage components into our design certification engine.”

This latest test series concludes a thorough testing campaign for NASA and its engine contractor. The agency conducted an initial series of 18 RS-25 hot fires as Aerojet Rocketdyne completed modifications to adapt the existing space shuttle main engines needed for early SLS missions. This included tests of two RS-25 flight engines.

The latest series involved five hot fire tests of RS-25 developmental engine No. 0525 for a total of 2,500 seconds. The series featured a new low-pressure fuel turbopump, flex ducts, restart sensors and ignition components, as well as 3D-printed valves and rigid ducts not previously tested. Fifty percent of the new 3D-printed components to be used on the new RS-25 engines were tested in the series. Other 3D-printed components are located on the new engine nozzle and will be validated during certification testing later this summer.

“This latest hot fire closes a great chapter in Stennis testing history,” said Chip Ellis, Stennis RS-25 test project manager. “Completion of the retrofit series could not have occurred without the dedicated, highly skilled workforce at Stennis Space Center. The test team has done an outstanding job getting us through this development period, and we look forward to continuing to test engines that will fly on SLS missions.”

With developmental testing completed, NASA plans to begin a series of 12 hot fires this summer on an RS-25 certification engine that is the identical design to future engines being manufactured for flight. It will feature all of the new components, including a new nozzle, in final flight configuration. A follow-up series of 12 tests will be conducted on RS-25 engine No. 0525 once it is modified with new components in final flight configuration as well. The dual series will demonstrate the new engine design is ready to fly.

Aerojet Rocketdyne is under contract to produce 24 new RS-25 engines using the updated design to support future Artemis missions beginning with Artemis V.

RS-25 tests at Stennis are conducted by a combined team of NASA, Aerojet Rocketdyne, and Syncom Space Services operators. Syncom Space Services is the prime contractor for Stennis facilities and operations.

Read the entire feature here.

Watch Engineers Join SLS Rocket Parts to Form Artemis II Core Stage

This time-lapse video shows how NASA joined the Space Launch System rocket’s core stage forward assembly with the 130-foot liquid hydrogen tank for the Artemis II mission on March 18. This completes assembly of four of the five large structures that make up the core stage that will help send the first astronauts to lunar orbit on Artemis II. The 66-foot forward assembly consists of the forward skirt, liquid oxygen tank, and the intertank, which were mated earlier. Engineers inserted 360 bolts to connect the forward assembly to the liquid hydrogen tank to make up the bulk of the stage. Only the engine section, which is currently being outfitted and includes the main propulsion systems that connect to the four RS-25 engines, remains to be added to form the final core stage. All parts of the core stage are manufactured by NASA and Boeing, the core stage lead contractor at the agency’s Michoud Assembly Facility. Currently, the team is building core stages for three Artemis missions. The first core stage is stacked with the rest of the SLS rocket, which will launch the Artemis I mission to the Moon this year. Together with its twin solid rocket boosters, the core stage will produce 8.8 million pounds of thrust to send NASA’s Orion spacecraft, astronauts, and supplies beyond Earth’s orbit to the Moon. SLS and Orion form the foundation for Artemis missions and future deep space exploration. (NASA/Eric Borderlen, Michael DeMocker)

Preparations Underway for Building 4200 Decommissioning, Replacement

Site preparation activities have begun for the phased decommissioning and replacement of Building 4200, the former headquarters for NASA’s Marshall Space Flight Center. Safety fencing around the perimeter of the work site was installed March 28. Internal demolition and removal efforts will take place for several months, with the final structural takedown scheduled for late 2022 or 2023. The project will make way for state-of-the-art “green” facilities that will make more efficient use of taxpayer dollars and house new generations of engineers, scientists, and support teams. The new Marshall headquarters – Building 4221– is a multiuse facility with modern collaboration spaces. (NASA/Charles Beason)

Marshall, NASA Office of Procurement Highlight Updates at Small Business Alliance Meeting

NASA’s Marshall Space Flight Center hosted its 33rd Small Business Alliance meeting in conjunction with NASA’s Office of Procurement on March 31. The meeting was held virtually and featured presentations focusing on updates on acquisition and agency product service lines from Marshall’s Office of Procurement and other NASA centers. “The NASA Office of Procurement recognizes small business is a vital, mission-critical partner,” said Jason Detko, left, NASA’s deputy assistant administrator for Procurement and agency Procurement ombudsman/competition advocate. “Engagements such as the Marshall Small Business Alliance Meeting enable us to strengthen our industrial base and infuse new technology to support our agency’s mission.” Marshall Associate Director Rae Ann Meyer agreed. “The small business community is vital to NASA’s mission,” she said, “by providing the expertise, services, and other critical capabilities that we need to be successful.” More than 670 attendees took part in the virtual event. (NASA)