Quick Facts

Year Built: 1938

Historic Eligibility: National Register Eligible

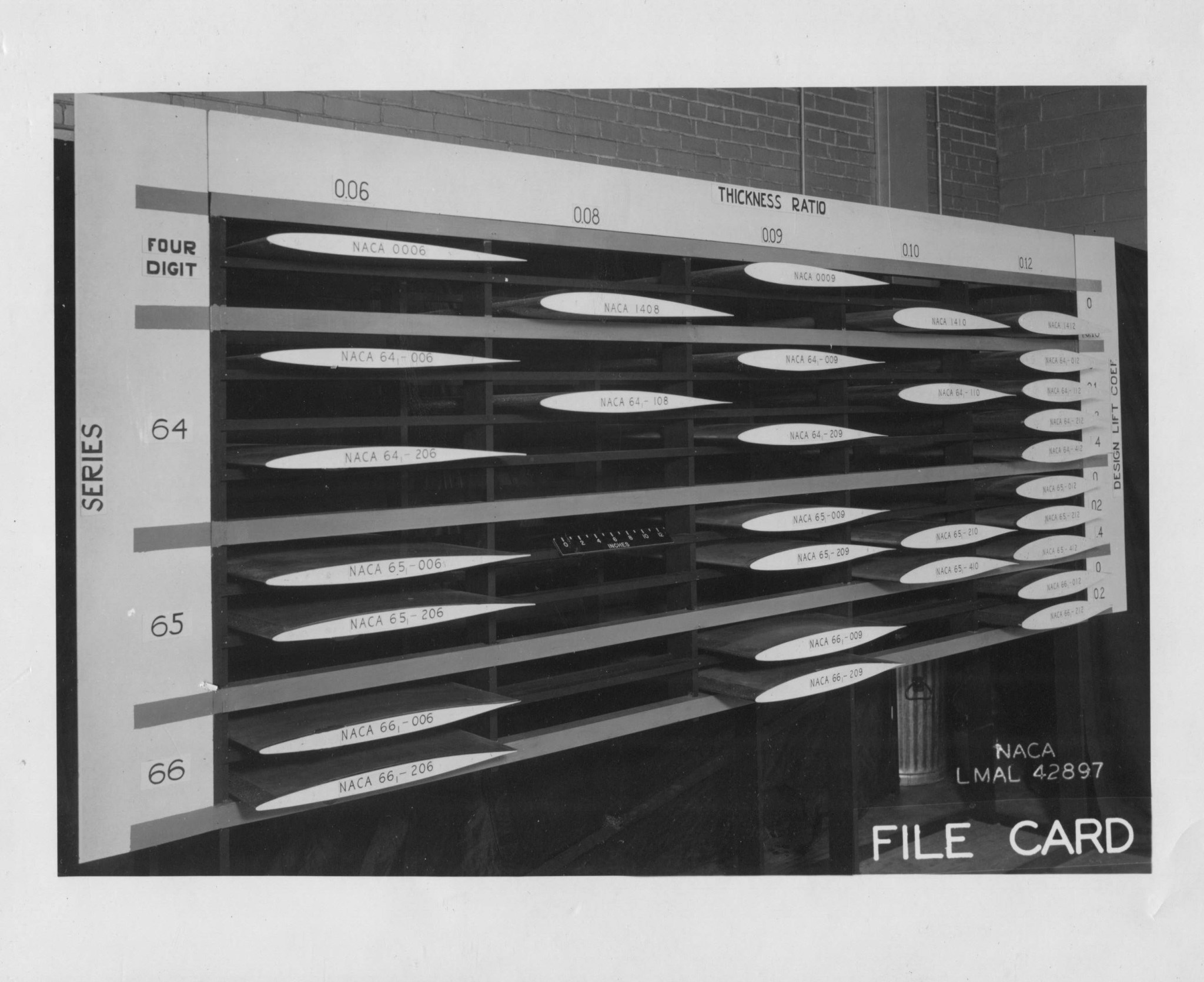

Important Tests: Airfoils

History

Building 583 in the NASA East Area has been the site of several historically significant wind-tunnel activities since it became operational in 1938. The following discussion provides information on research activities for some of the most important programs conducted in Building 583.

Ice Tunnel

In the late 1920s, Langley researcher Eastman Jacobs began an aggressive campaign to acquire a new wind tunnel capable of operation with extremely low levels of turbulence in its test section airstream. Low levels of turbulence are critical for certain aerodynamic applications, such as laminar flow airfoils and low-drag configurations.

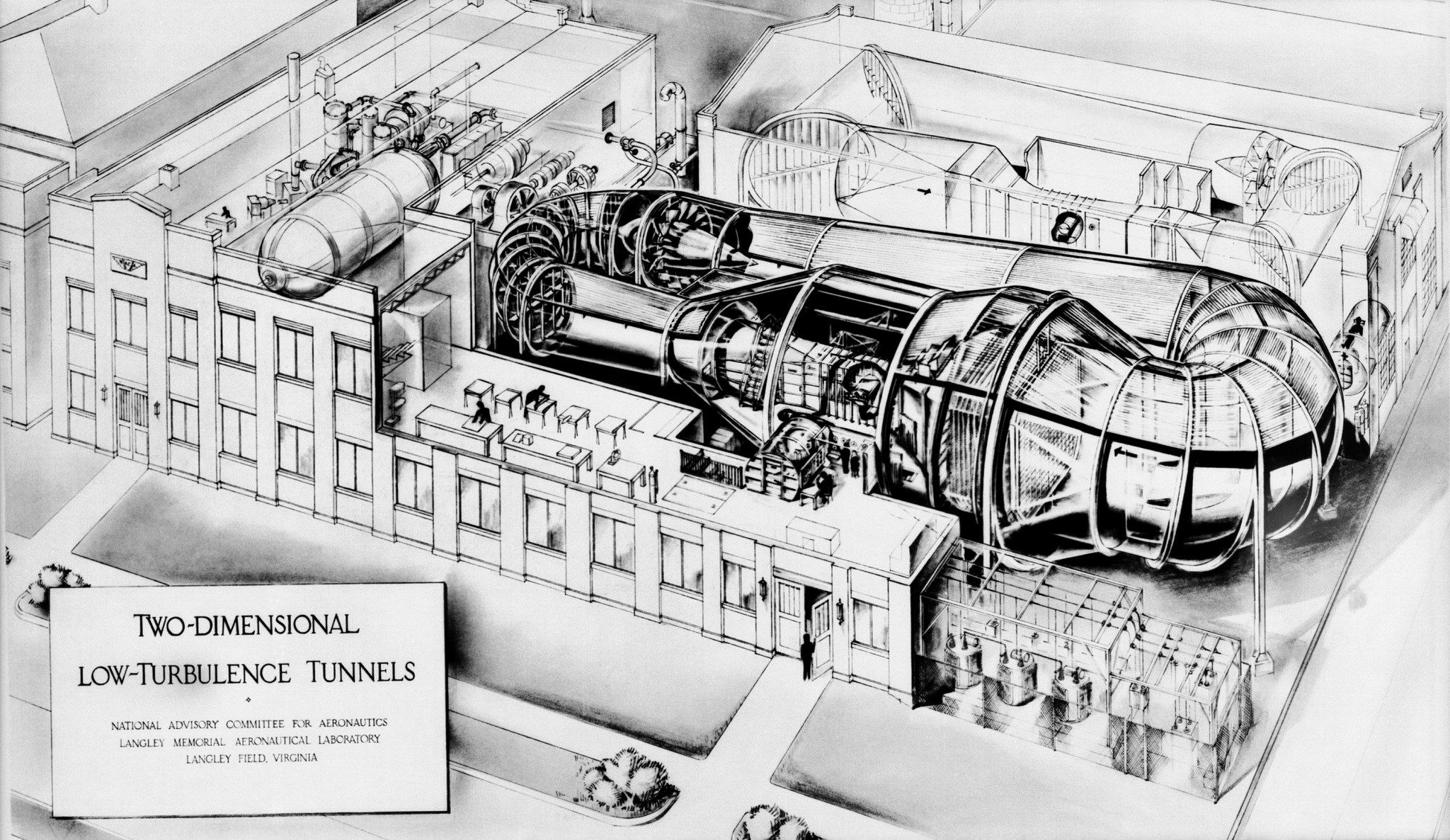

Methods to reduce the turbulence included the use of high contraction ratios (ratio of settling-chamber area to test-section area) in combination with extensive honeycomb and fine-meshed screens to smooth the airflow in the settling chamber. Jacobs also envisioned using a pressurized tunnel to obtain test conditions more representative of flight. Before investing in a pressurized tunnel of such a novel concept, it seemed wise to build a relatively cheap full-scale model to work out any unexpected engineering and air flow problems that might arise.

Jacobs’s request for a new tunnel based on low turbulence levels was not accepted by Langley’s management, in part on the basis that Congressional approval for the tunnel would be difficult to achieve based on the vague technical factors involved. However, aircraft icing problems were a high-priority issue for the NACA mission at the time, and Jacobs and Ira Abbott commenced to designing an “icing tunnel” which had the same dimensions and layout as a desirable low-turbulence tunnel.

Using this ploy, a pilot tunnel of the low-turbulence tunnel was built as the Langley Ice Tunnel with the stated purpose of investigating ice formation on aircraft components.

The closed-throat tunnel was built of wood with a sheet steel lining and included refrigerating equipment and installation on the outside.

Built in Building 583 (then known as Building 188), its rectangular test section measured 3-feet wide and was 7.5-feet high. Powered by a 200-horsepower motor, the tunnel was capable of test speeds up to about 155 mph. The Ice Tunnel became operational in June 1938 and served its alleged purpose with a few rapid investigations of icing.

During the studies emphasis was placed on the ability of coatings and heat from heated air ducts to prevent ice formation and to de-ice wings of aircraft. Flight tests were conducted by Langley’s flight division for correlation with the tunnel test results. The minimum temperature for icing tests in the tunnel was about 20° F and the airspeed was about 80 mph.

Natural precipitation was simulated by spraying water into the airstream through a spray nozzle. A source of heated gas, such as would be available from an engine exhaust, was simulated by blowing air through a multi-tube electric heater. The icing program was led by Lewis A. Rodert, who would later be awarded the Collier Trophy for his pioneering efforts in the field. Langley’s efforts in icing research were transferred to the NACA Ames Laboratory in 1940, along with Rodert.

Two-Dimensional Low Turbulence Tunnel

After its brief role in Langley’s research on icing, the Ice Tunnel was modified for its intended mission in aerodynamic evaluations of the low-turbulence tunnel concept. The refrigeration equipment in the Ice Tunnel was removed and the settling chamber of the tunnel was converted with arrays of honeycomb and screens to reduce the turbulence levels to extremely low levels. The first airfoil test for a low-drag airfoil was carried out in June 1938 and the measured aerodynamic drag of the new airfoil was about 50 percent less than had previously been measured on airfoils of comparable thickness. This highly impressive result led to preparations to build a pressurized low turbulence tunnel to be known as the Langley Two-Dimensional Low Turbulence Pressure Tunnel (LTPT). Having accomplished its pioneering mission, the Langley Two-Dimensional Low-Turbulence Tunnel was dismantled in 1947 and Building 583 was subsequently used to accommodate the Langley 26-Inch Transonic Blowdown Tunnel.

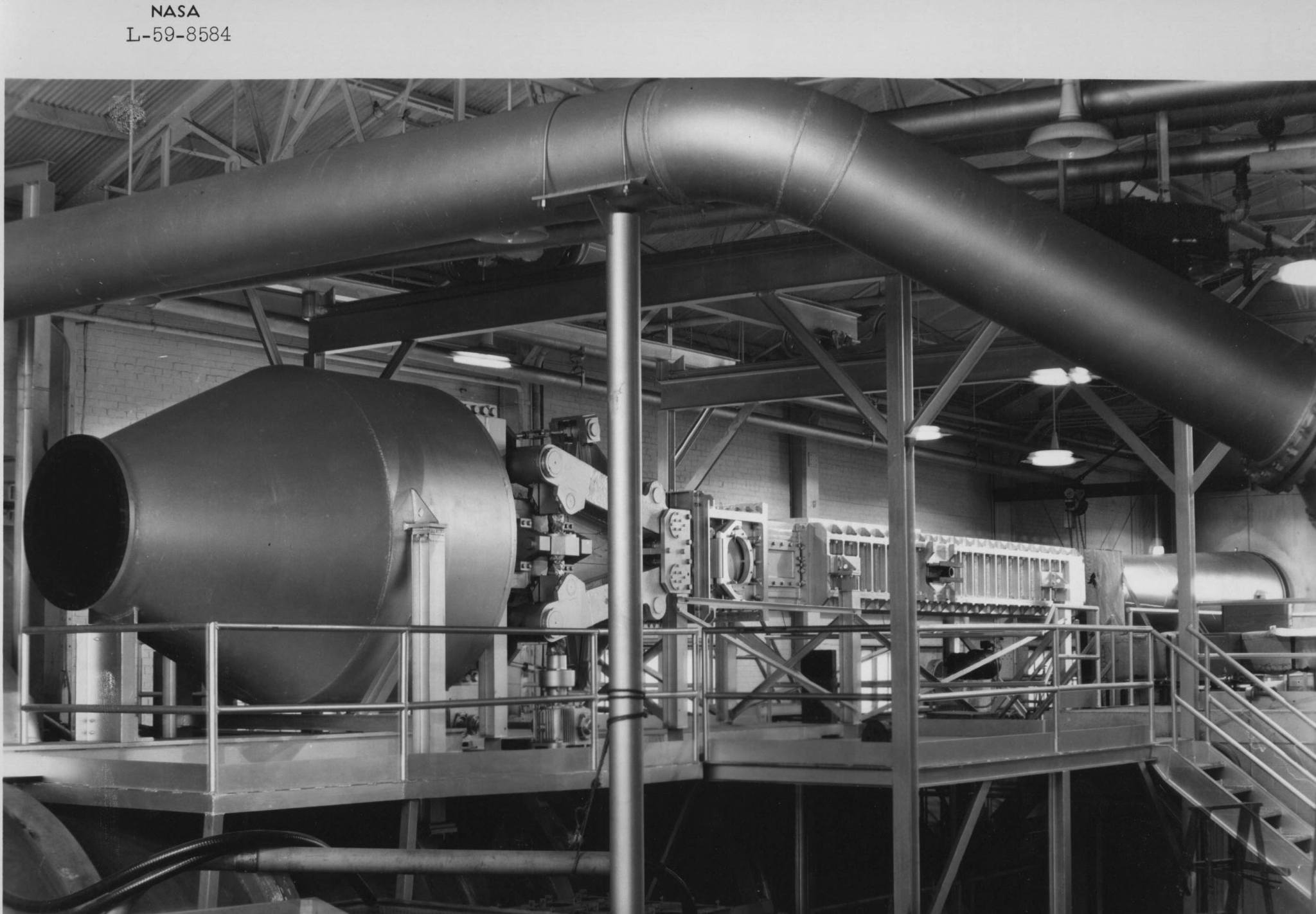

26-Inch Transonic Blowdown Tunnel

After 1955 testing in the Langley Two-Dimensional Low-Turbulence Pressure Tunnel (LTPT) decreased and the facility was used as a high-pressure air storage tank for a complex of smaller transonic and hypersonic tunnels. The first of these tunnels was the Langley 26-Inch Transonic Blowdown Tunnel (TBT) which was constructed to study transonic aerodynamic phenomena and to investigate flutter characteristics at transonic conditions.

The TBT became operational in October 1950 using compressed air from the LTPT as a power source. High-pressure air could be transferred to the TBT through three precise quick-acting valves. The octagonal test section was slotted and measured 26.4 inches across flats with an operational Mach number range from 0.5 to 1.45. Models in the TBT could be mounted on an internal 5-component electrical strain-gage balance (no axial-force measurements). For flutter testing, test runs on the order of 10 to 20 seconds were typical.

After results of the flutter tests became known in the aeronautical community in 1953, the tunnel was in great demand for flutter testing. Flutter studies were made in the TBT of components of about 15 high-priority aircraft and missile configurations between 1954 and 1959. The TBT was deactivated in the 1970s, but was returned to use for flutter tests such as the Space Shuttle in 1973.

20-Inch Variable Supersonic Tunnel

The availability of high-pressure air sources from the LTPT complex provided a stimulus for researchers to develop additional high-speed blow-down test facilities in Building 583.

After the Langley 26-Inch TBT was used with great success, the Langley 20-Inch Variable Supersonic Tunnel was designed in 1950 as a horizontal tunnel mounted above the TBT. The settling chambers of both tunnels were interconnected through an isolation valve and manifold so that both could make use of a regulator system to control the stagnation pressure. The 20-inch tunnel operated until 1965.

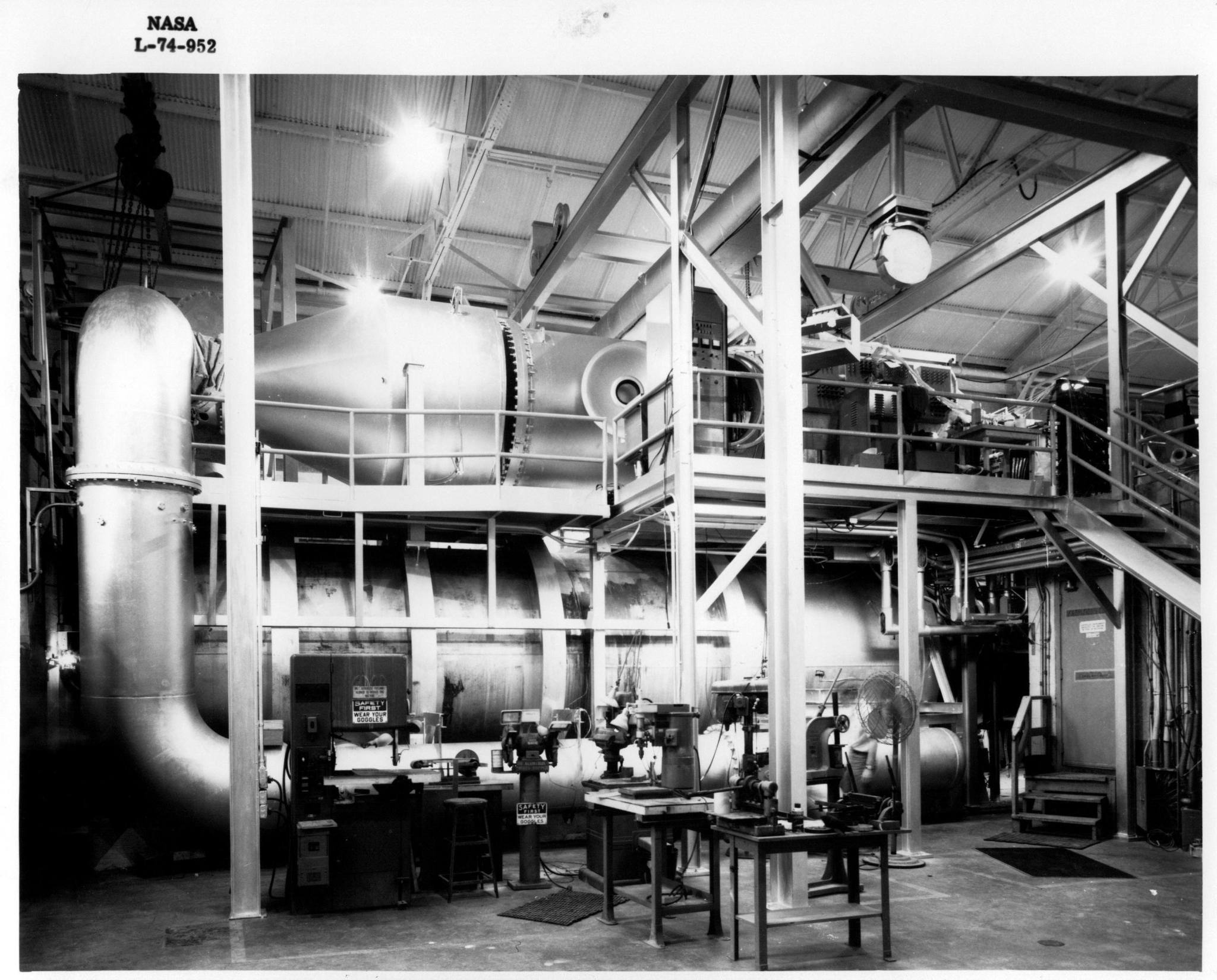

6- by 28-Inch Transonic Tunnel

In 1968, Langley instituted a program to develop tunnel test facilities for small two-dimensional airfoil sections at subsonic through transonic speeds. A modification to the non-operational 20-Inch Variable Supersonic Tunnel was proposed to permit such tests, citing the large cost savings that would accrue from using the existing hardware. The modification was completed in mid-1974 with operational testing beginning in late 1974.

The modified facility was designated the Langley 6- by 28-Inch Transonic Tunnel with operational Mach numbers from 0.3 to 1.2. The facility operated in a blowdown mode at stagnation pressures up to 150 lb/ft2, which was the pressure of the air storage tank.

The tunnel was a horizontal, two-dimensional wind tunnel with slotted top and bottom walls. Typical models tested in the facility had wing spans of about 6 inches and a wing chord of about 4 inches with extensive pressure instrumentation.

Hypersonic Flow Apparatus

The Langley 15-Inch Mach 10 Hypersonic Flow Apparatus (HFA) was one of the first hypersonic wind tunnels at Langley. The tunnel was used for investigations of hypersonic forces, pressures, heat transfer, and flutter. Flow through the 15-inch test section exhausted into a vacuum tank. The test running time available under blowdown conditions was about 180 seconds. The apparatus included a Schlieren system that permitted the visualization of shock interactions. The Hypersonic Flow Apparatus was moved to Building 1251 in 1973.

Search the NASA Technical Reports Server for additional examples of research conducted in this facility.

Related Materials

Characteristics of Nine Research Wind Tunnels of the Langley Aeronautical Laboratory

1942 Ice Tunnel Floor Plan

Langley Memorial Aeronautical Laboratory Description