Technology often develops through circuitous paths, but the one linking NASA’s cutting-edge autonomous robotic vehicles with gourmet coffee might be one of the more surprising.

In 2006, Matt Walliser, now chief engineer at San Francisco-based Blossom Coffee, took on an internship at the Carnegie Mellon Innovations Laboratory at NASA Research Park, part of Ames Research Center in Moffett Field, California. He spent four summers at the lab and at Ames’ Exploration Aerial Vehicles (EAV) Laboratory, starting when he was a high school student and continuing while he worked toward his mechanical engineering degree.

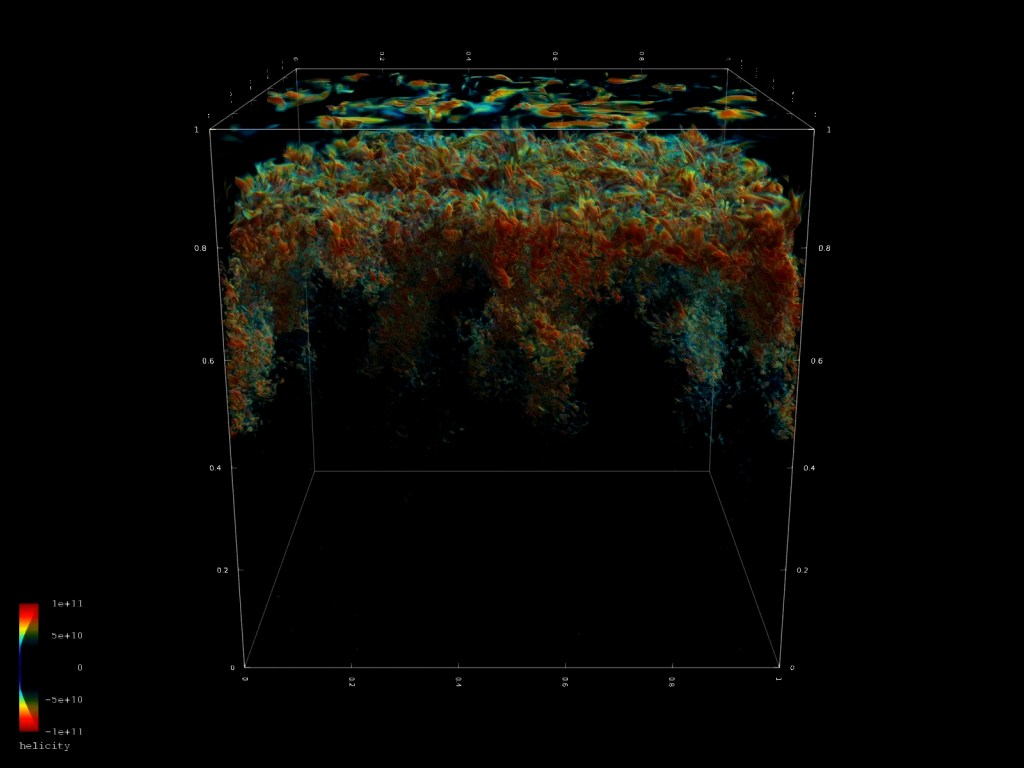

There, he worked on a class of control systems — proportional-integral-derivative (PID) controllers — that is common on rockets, missiles and other aircraft. PID controllers work by continually monitoring and correcting the output of a controlled system through feedback loops.

Among other purposes, the team in Ames’ lab used the technology to keep rovers moving at constant speeds over varying terrain. But after graduation, Walliser realized the technique could also help make better coffee.

Dialing In the Heat

Coffee made from the same beans can taste significantly different when brewed at different temperatures, Walliser explains. “Most coffee machines will control the temperature within five to 10 degrees, but the average coffee drinker can tell the difference between coffees brewed as little as two degrees apart.”

But how to control the temperature more accurately? Walliser figured PID controllers could help.

He was working with Jeremy Kuempel, who had approached him with his idea for a high-end, precision coffee maker. The two would found Blossom Coffee Inc. in 2011.

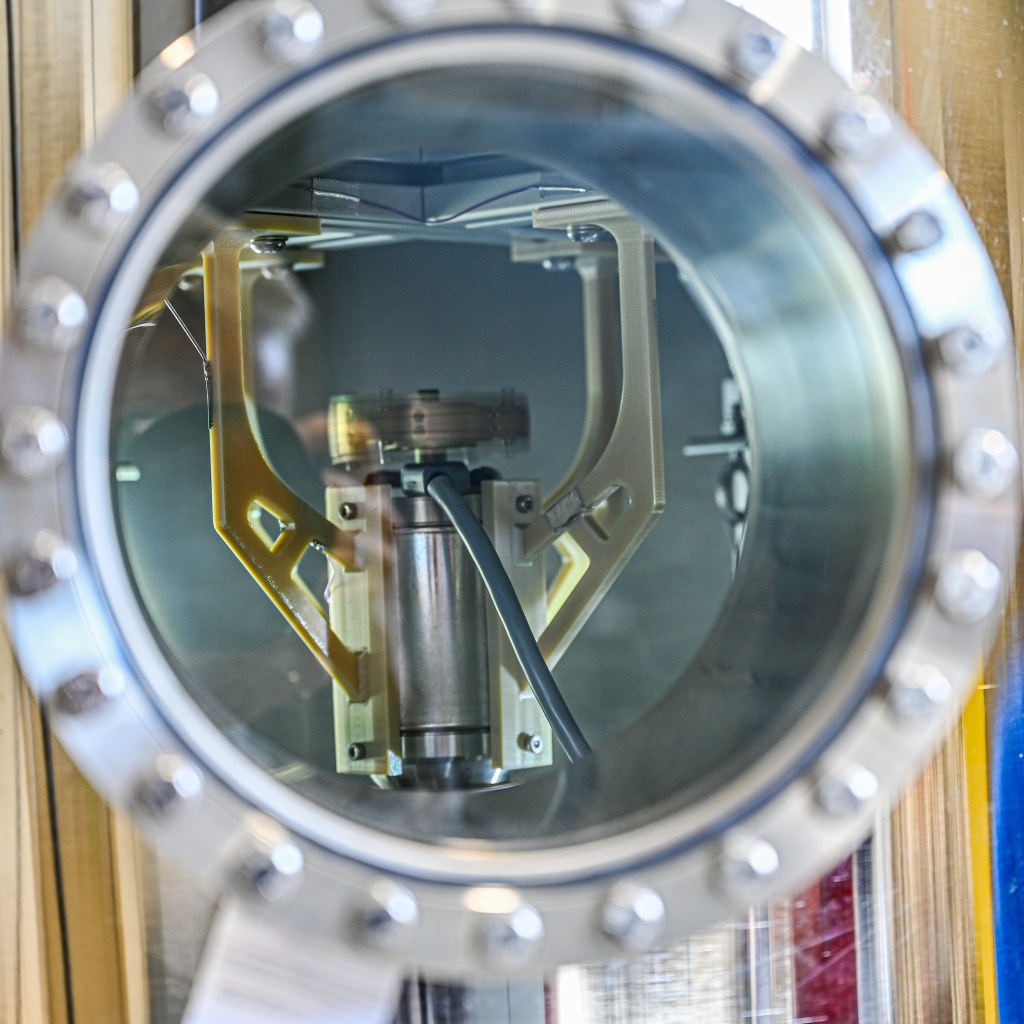

Drawing on the expertise he developed at Ames, Walliser enabled Blossom’s machine, called the Blossom One Brewer, to control the average temperature of water to within one degree. It also keeps all the coffee grounds within 10 degrees of each other, regardless of their place within the brewing basket, a temperature gradient significantly narrower than in most coffeemakers, and it automatically corrects heating and fluid delivery for altitude, barometric pressure and ambient temperature.

‘Bots Won’t Replace Baristas

Tight temperature controls allow the user to consistently produce the same brew. They also let the machines change temperature from one cup to the next within a few seconds. Recipes for different beans can be shared and downloaded via the Internet.

Walliser calls the coffeemakers “semi-automatic,” noting that, while they control temperature and extraction time, the grind and the stirring time are in the hands of the barista, making the brewing process flexible. “It’s still a craft product, and you still need training to use it, but it takes over the things that are difficult to control by hand,” he says.

The first prototype Blossom Limited machines went on sale in 2013 for $11,111. By early 2015, the company had set up production in Japan and was offering the Blossom One for about half the price of the prototype. The current product is a single-cup brewer marketed to cafés and coffee shops, but Walliser says the company hopes to offer a home version in the future.

Walliser credits the freedom interns have while working in the NASA labs for the innovations he’s developed. “Being able to do engineering in a self-directed manner isn’t an experience you usually get in high school, or even college,” he says. “Having that kind of real-world experience really allowed me to excel in school and build the skills I have today.”

To learn more about this NASA spinoff, read the original article from Spinoff 2016.