Analogs & Mockups

Introduction

NASA Johnson Space Center (JSC) offers a range of facilities to support mission development, crew training, equipment testing, and real-time mission troubleshooting.

Analogs are designed to solve the unique challenges of living and working in extreme environments. JSC provides realistic surface analog environments to evaluate major systems, understand human performance, perform integrated systems testing and assess mission profiles. JSC also has the capability to simulate reduced gravity environments and rough extraterrestrial terrain. These simulations can be utilized for testing, development and training for both human and hardware applications.

Mockups are direct counterparts to human-rated space vehicles for integrated training and mission assessments. These provide the opportunity for interior layout testing and operations evaluation. Each of the mockups has its own unique aspects that create the most true-to-life simulation possible.

Two of the most unique facilities JSC has include the Neutral Buoyancy Laboratory (NBL) and Space Vehicle Mockup Facility (SVMF), which both provide some of the highest fidelity space mockup and analog experiences in the world. We invite collaborators to join forces with us, leveraging our extensive and diverse capabilities in analogs and mockups to pioneer groundbreaking advancements in space exploration and astronaut well-being.

Analogs

Crew Health and Performance Exploration Analog

Summary | Crew Health and Performance Exploration Analog (CHAPEA) is a series of analog missions that will simulate year-long stays on the surface of Mars. Each mission will consist of four crew members living in Mars Dune Alpha, an isolated 1,700 square foot habitat. During the mission, the crew will conduct simulated spacewalks and provide data on a variety of factors, which may include physical and behavioral health and performance.

To learn more: https://www.nasa.gov/humans-in-space/chapea/

Details | Known as Mars Dune Alpha, the 3D printed structure will simulate a Mars habitat to support long-duration, exploration-class space missions. Life in Mars Dune Alpha will resemble the expected experience for those living in a future Mars surface habitat. The layout of the 3D printed habitat was designed to provide separate areas within the habitat for living and working.

- Habitat Print Stats:

- Tech: ICON’s next generation Vulcan construction system

- Dimensions: 1,700 square feet

- Material: lavacrete

- Mars Dune Alpha features include:

- Four private crew quarters

- Dedicated workstations

- Dedicated medical station

- Common lounge areas

- Galley and food growing stations

Human Exploration Research Analog

Summary | Human Exploration Research Analog (HERA) is a unique three-story habitat designed to serve as an analog for isolation, confinement, and remote conditions in exploration scenarios.

Details |

- Mission Control Center (MCC) for real-time interaction with HERA crew members

- 24/7 mission video surveillance with audio, recorded during mission

- Communication delay, voice and/or text, up to 20 minutes each way

- Simulation of Acquisition of Signal/Loss of Signal of varying duration

- Individual crew sleeping quarters for 4 crew members

- HERA-provided Windows-based laptops and iPads for each crewmember for investigator data collection

- Flight Simulators to support an exploration mission scenario

- Virtual reality simulation for simulated EVA tasks

- Biological sample collection pre, during and post mission

- Medical Workstation (Remote medical procedures and examinations)

- Adjustable LED lighting on L2

- Simulated stowage module (pass through for hardware, biological samples, and trash)

- Modifiable virtual window views

- Exercise equipment (aerobic and resistive) to simulate daily operational activities

- Heart Rate Monitor to support exercise or research

- Actigraphy

- Simulated Environmental Control and Life Support System (ECLSS)

- 3D printer to support vehicle maintenance and operational tasks

- Flight-similar galley capabilities for preparing meals (plumbed water supply)

- Shower/sink with hot and cold running water for crew hygiene

Planetary Test Analog Site (The Rock Yard)

Summary | NASA JSC Rock Yard provides a large outdoor multi-acre test area which simulates general features of the lunar and Martian surface terrain environment consisting of various slopes, grades, simulated craters, and strewn rock field conditions.

Details | Rock Yard Services

- Test planning, consultation, and integration

- 110 volts AC (VAC) electrical power available

- Space suit hardware and test subject support on an “as required” cost-basis

Beneficial Features

- Test hardware and/or concept of operations in simulated planetary surface terrain environments

- Existing facilities, infrastructure, and ground support equipment

- Full operational capability and readiness

- Ability to upgrade/reconfigure as needed

- Capabilities for demonstrating human and robotic interactive test activities

- Analog test site area capable of enabling large scale, high fidelity integrated test activity scenarios

- Proximity to other JSC and regional test facilities

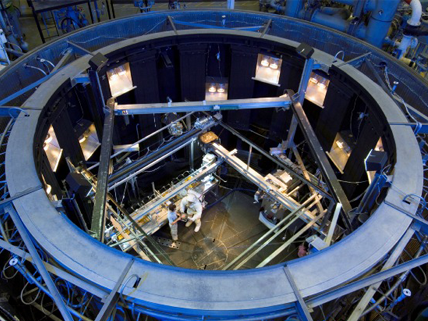

JSC Chamber B

Summary | Chamber B is used for human testing in a vacuum environment and for crewed space operations testing.

Details |

NASA JSC Chamber B provides space environmental testing with vacuum thermal conditions. Chamber B is a human-rated chamber equipped with a traversing monorail that provides weight relief to one suited crew member at a time. The chamber also has dual crew airlocks to provide easy access to the test articles as well as a means of transporting test crew members to the test environment and back during tests. Chamber B has an internal volume of 7.6 m (25 ft) diameter x 7.9 m (26 ft). Its usable test volume and high-fidelity space simulation capabilities are adaptable for thermal vacuum testing of a wide variety of test articles. The low temperature range of the chamber is -300° F. The pressure range of the chamber is from 1×10^-6 torr to 760 torr.

Partial Gravity Simulator (POGO)

Summary | The Partial Gravity Simulator (POGO) consists of servos, air bearings, and gimbals to provide accurate simulations of reduced gravity.

Details |

- Utilized for astronaut training and for evaluating the crew’s ability to perform tasks in simulated partial and microgravity

- Utilized in the development and evaluation of Extravehicular Activity (EVA) equipment and techniques and for training in low or 0G mass handling

- An integrated process to support operations assessments, integration, test readiness, and execution

- Mission examples include human locomotion studies and training exercises

Precision Air Bearing Floor (PABF)

Overview | The Precision Air Bearing Floor (PABF) allows astronauts to move large objects as they might in space.

Details | The PABF is an extremely smooth and flat surface that provides a 2-dimensional simulation of the weightless environment of space by floating objects on a thin cushion of air. It is designed to support rendezvous and contact testing that require low friction movement of test articles and utilized in the development and evaluation of Extravehicular Activity (EVA) equipment and techniques and for training in low or 0g mass handling. Test articles are mounted on perforated pads that distribute a cushion of compressed air between the pads and the floor and air bearings use compressed air to suspend and enable frictionless movement of mockups and hardware. It is an integrated process to support operations assessments, integration, test readiness, and execution.

Active Response Gravity Offload System (ARGOS)

Overview | Active Response Gravity Offload System (ARGOS) is designed to simulate reduced gravity environments from earth gravity to microgravity. A continuous dynamic offload of a subject’s weight (or portion thereof) is maintained by a robotic motion control system that actively follows the subject’s motion within the system’s operational volume. ARGOS is capable of offloading humans (both in shirtsleeves and space suits), small rovers, and robots for testing, training, process development, and human research in simulated reduced gravity environments.

Details | ARGOS 2 resembles an overhead bridge crane 41 x 24 x 25 feet in size. Sensors in the horizontal axes (X and Y) and vertical axis (Z) obtain displacement and force changes of the payload, allowing a computer-controlled winch to provide superimposed constant force offload above the payload’s center of mass.

ARGOS 2 Specifications

- 750lb offload capability

- 13’(X) x 30’(Y) x 15’(Z) workspace

- System wide communication for test subjects and support teams

- Motion tracking supported by AIBEL

- NASA Space suit support supported by Crew and Thermal Systems Division

- Pressurized breathing air

- Cooling water for suits

Motion capabilities

- Suited Configuration: 4 ft/s vertical, 6.5 ft/s horizontal

- Unsuited configuration: 11 ft/s vertical, 6.5 ft/s horizontal

- Variety of Gimbals (payload interfaces) to support suited, unsuited, and unmanned testing

Supported Test Types

- Suited or unsuited

- EVA in microgravity, Lunar, or Martian gravity environments

- EVA tools, process development

- Biometric studies in reduced gravity environments

- Robotic systems payloads

- New test types are possible

ARGOS technology is available in the NASA Patent Portfolio: https://technology.nasa.gov/patent/MSC-TOPS-60

Space Vehicle Mockup Facility (SVMF)

Summary | The Space Vehicle Mockup Facility (SVMF) provides world class training for space flight crews and their support personnel and high-fidelity hardware for real-time mission support. The SVMF is for mockup-based training, reduced gravity training, technique and procedures development and real-time mission support.

For more information, see www.nasa.gov/johnson/space-vehicle-mockup-facility/

Details |

- Scheduling processes optimize SVMF resources to enable numerous simultaneous training and operations events

- An integrated process to support operations assessments, integration, test readiness, and execution

- Instructor/operator station that enables the instructor team to control the training scenarios as either a simulated MCC or via providing instructor insights

- Training scenarios include nominal timeline activities and simulated emergencies by inputting system malfunctions

- Video and audio systems supported with a local area network

- Mockup connectivity to Training Systems can enable interactive crew stations

- High-fidelity mockups support engineering and flight operations evaluations for the ISS and Artemis Programs

- Numerous standalone racks/facilities support targeted training events

- Activities supported include emergency operations, on-orbit maintenance, photo/TV, stowage and handling, EVA/airlock operations, routine operations, and scientific payload operations

- All mockups and part-task trainers are available to support troubleshooting on the ground any time problems develop on-orbit in real-time

- Customers supported include: NASA Programs, ISS International Partners, commercial space flight companies, and exploration partners

ISS Mockups

Summary | Mockups of all International Space Station habitat modules allow for integrated training and operational assessments.

Details |

- High-fidelity ISS mockups support engineering and operations evaluations such as cargo transfer operations, on-orbit stowage evaluations, fit checks, and procedure development and verification

- An integrated process to support operations assessments, integration, test readiness, and execution

- Activities supported include emergency operations, on-orbit maintenance, photo/TV, stowage and handling, EVA/airlock operations, routine operations, and scientific payload operations

- All mockups and part-task trainers are available to support troubleshooting on the ground any time problems develop on-orbit in real-time

Orion Capsule Mockup

Summary | An Orion capsule mockup allows for training and operations assessments.

Details |

- The SVMF Orion capsule mockup is used to support Artemis exploration activities

- Utilized for interior layout assessments and mission training

- Capable of supporting engineering and operations evaluations such as on-orbit stowage, fit checks, emergency operations, photo/TV, and procedure development and verification

- An integrated process to support operations assessments, integration, test readiness, and execution

- All mockups are available to support troubleshooting on the ground any time problems develop on-orbit in real-time

Gateway Mockups

Summary | Mockups of Gateway modules are available to allow for training and operational assessments.

Details |

- Habitation and Logistics Outpost (HALO) mockup at the Space Vehicle Mockup Facility (SVMF) represents the first pressurized element for NASA’s lunar Gateway

- Habitable living space, science operations, mission sortie preparations, communication with ground and lunar assets, and space for physical exercise equipment for 4 crew for up to 30 days

- The HALO mockup can be used for engineering and operations evaluations, interior layout assessments and mission training

- Additional Gateway mockups will be added to the SVMF in the future

- An integrated process to support operations assessments, integration, test readiness, and execution

- All mockups are available to support troubleshooting on the ground any time problems develop on-orbit in real-time

Space Vehicle Mockup Facility (SVMF) Standalone Training Racks & Facilities

Summary | Numerous Space Vehicle Mockup Facility (SVMF) standalone racks and facilities support targeted training events.

Details |

- E-Wing: High-fidelity hardware qualification unit with functional components including solar arrays, blanket box, and mast canister assembly

- High fidelity EVA training Area (HETA): Area dedicated to providing hardware familiarization for EVA Orbital Replacement Units (ORUs)

- Regenerative ECLSS: High-fidelity mockups of the regenerative environment control and life support system (ECLSS) racks, oxygen generation system (OGS), and water recovery system (WRS)

- AV racks: High-fidelity mockups of the avionics racks (AV), which are outfitted with audio and video components and subsystems

- Solar Alpha Rotary Joint (SARJ) Training Assembly (STA): High-fidelity trainer of the S3/S4 truss consisting of the SARJ race ring, electrical connections, and diagonal braces

- Station Hardware Equipment Lab (SHEL): Houses a complete set of ISS on-orbit maintenance tools, select diagnostic equipment, and other ISS tools/tool kits that are used to train crew members for ISS tool skills

- Vestibule Operations Trainer (VOT): High-fidelity training of the hardware that exists between attached modules

- Waste Management System (WMS): Facility used to train general operations, as well as preventive and corrective maintenance of the ISS toilets

- Window Observational Research Facility (WORF) Rack: Utilizes the US Lab Nadir window to support various types of photography and observation

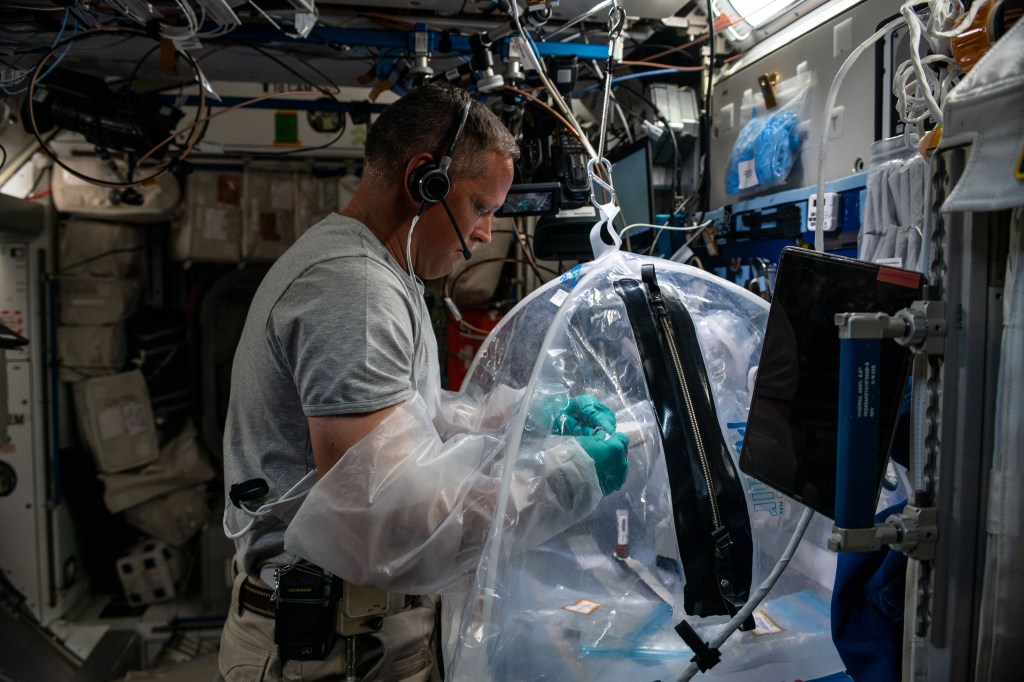

Payload Development Laboratory

Summary | The Payload Development Laboratory (PDL) is a flight-like cylindrical International Space Station (ISS) module mockup in the Space Vehicle Mockup Facility that is used for human research training, testing, simulations, procedure development, scientific payload and interface training.

Details |

- Full scale US laboratory mockup and associated control consoles used for Human Research Facility (HRF) Rack training and high-fidelity payload rack training

- An integrated process to support operations assessments, integration, test readiness, and execution

- Two high fidelity Human Research Facility (HRF) racks (as on ISS) and other flight-like human research hardware

- Flight-like voice, data, and video capabilities

- *Flight-like power and utility connections and HRF laptops with flight software

- Ground support personnel consoles with data, voice, and video connections to module interior

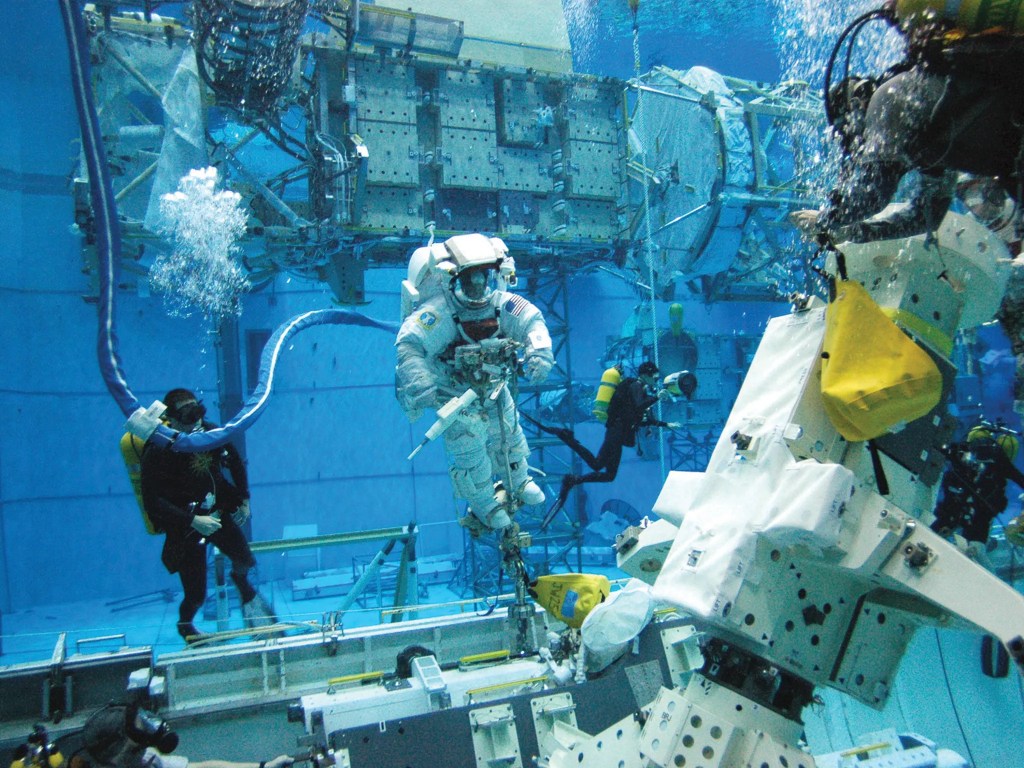

Neutral Buoyancy Laboratory (NBL)

Summary | The Neutral Buoyancy Laboratory (NBL) is one of the world’s largest indoor pools and can support multiple large-scale operations utilizing both underwater and topside assets simultaneously. The NBL is utilized for mission planning, procedure development, hardware verification, astronaut training, and refinement of time-critical operations necessary to ensure mission success.

For more information, see www.nasa.gov/johnson/neutral-buoyancy-laboratory/

Details |

- NBL has a volume of 6.2 million gallons with dimensions of length: 202 ft (61.5 m), width: 102 ft (31.1 m), and depth: 40 ft (12.2 m)

- Chlorinated fresh water environment with a temperature range of 84°-86° F (29.9°-30° C)

- An integrated process to support operations assessments, integration, test readiness, and execution

- Facility scheduling capabilities enable multiple large scale operations simultaneously

- Multiple integrated control rooms

- Clean climate controlled environment

- Extensive video, audio, and instrumentation capabilities

- Multiple crane systems for equipment handling

- SCUBA and surface supplied dive systems

- On-site engineering and technical services

- Co-located logistics and manufacturing facility

- ISO level 8 clean room to support maintenance and repair capabilities

- Located next to the Houston Ellington Airfield with access to a taxiway

- Within the facility, the NBL has a hyperbaric chamber, a hypobaric altitude chamber, a medical treatment room and locker room facilities

- Classroom, meeting, high-bay work areas, and outdoor space to support training or hardware storage

- World class safety culture

Human Rated Underwater Robotic System

Summary | The Neutral Buoyancy Laboratory (NBL) Space Station Remote Manipulator System (SSRMS) is a full scale and fully functional underwater version of the ISS SSRMS used to support Extravehicular Activity (EVA) training.

Details |

- The Space Station Remote Manipulator System (SSRMS) trainer at the NBL is a full-scale, volumetrically correct, kinematically correct and hydraulically powered version of the Space Station RMS and can be located on one of two dedicated SSRMS stands/bases

- Utilized to support EVA training by providing a crew operating base and is capable of the movement of astronauts and approved NBL mockups to specific worksites

- Capable of supporting the following SSRMS control modes: manual augmented, single joint rate, and standby

- Includes integrated processes to support operations assessments, integration, test readiness, and execution

Buoyancy Manipulation

Summary | NASA JSC Neutral Buoyancy Laboratory (NBL) has expertise in manipulating buoyancy to support microgravity or lunar surface operations.

Details |

- Extensive Neutral Buoyancy Laboratory (NBL) experience manipulating buoyancy to simulate full or partial gravity and to make mass handling in the water more manageable

- Expertise in weigh out of crew and hardware for microgravity operations

- Ability to support weigh out of lunar suited crewmembers, tools, and hardware with 1/6 gravity and a realistic center of gravity

- An integrated process to support operations assessments, integration, test readiness, and execution

SCUBA and Surface Supplied Dive Operations

Summary | Neutral Buoyancy Laboratory (NBL) underwater operations are supported by both SCUBA and surface supplied dive systems.

Details |

- Exceptionally experienced and certified professional diving staff

- NBL diving involves operations support, reconfiguration, camera operations and safety diving functions

- Expertise in underwater lifting and weigh out operations

- Utilizes SCUBA and surface supplied dive systems, with nitrox and air capabilities

- On-site hyperbaric chamber and medical treatment capabilities

- ISO Level 8 Clean Room supporting maintenance and repair capabilities

- Dive Safety Board that evaluates all JSC diving operations

Logistics and Mockup Facility

Summary | At the Neutral Buoyancy Laboratory (NBL) the Logistics and Mockup Facility (LMF) provides on-site engineering, manufacturing, and technical services in support of NBL operations.

Details |

- The Logistics and Mockup Facility (LMF) consists of a large high bay and a series of workshops for building and maintaining equipment

- Vertically integrated engineering, design, and manufacturing support is provided by a cadre of highly skilled and certified personnel

- LMF services include mockup fabrication and repair, machine shop, sheet metal shop, welding, sewing, assembly, woodworking, and multi-disciplinary engineering

Analog Mission Planning

Human in the Loop Testing and Analog Mission Planning and Execution

Overview | NASA JSC has multiple teams that provide organizational expertise for analog mission planning and execution and integration of operational testing for space exploration. Human-in-the-loop (HITL) testing develops and assesses systems, innovations, operational approaches to inform strategic architectural concept of operations and evaluates whether systems meet human health and performance requirements.

Details | The Exploration Mission Planning Office (EMPO) and the Habitability and Human Factors teams at NASA JSC provide analog mission planning and execution of integrated operational testing for space exploration and evaluation of human health and performance requirements. Human-in-the-loop (HITL) testing capabilities include establishing and coordinating a multi-disciplinary approach for operational testing, integrating analysis and development components across NASA, and using the results of testing in relevant environments for closing technology, exploration, and science knowledge questions, gaps, and risks.

Related Patents

Full-Size Reduced Gravity Simulator For Humans, Robots, and Test Objects