Spacecraft Test Facilities at NASA Goddard

NASA’s Goddard Space Flight Center is home to different facilities used to test spacecraft and instrumentation in environments that simulate conditions that the spacecraft may be exposed to during launch operations and while in space.

Acoustic Test Chamber

It’s true that in space no one can hear you scream. Blastoff, on the other hand, can make quite a racket, which is why engineers use the Acoustic Test Chamber. In this 42-foot-tall chamber, technicians expose payloads to the noise of a launch with the help of 6-foot-tall speakers.

The speakers (more accurately called horns) use an altering flow of gaseous nitrogen to produce a sound level as high as 150 decibels for two-minute tests. That’s about the level of sound heard standing next to a jet engine during takeoff.

The speakers are still audible – at greatly reduced volume – outside the chamber, even through the insulation of massive metal doors.

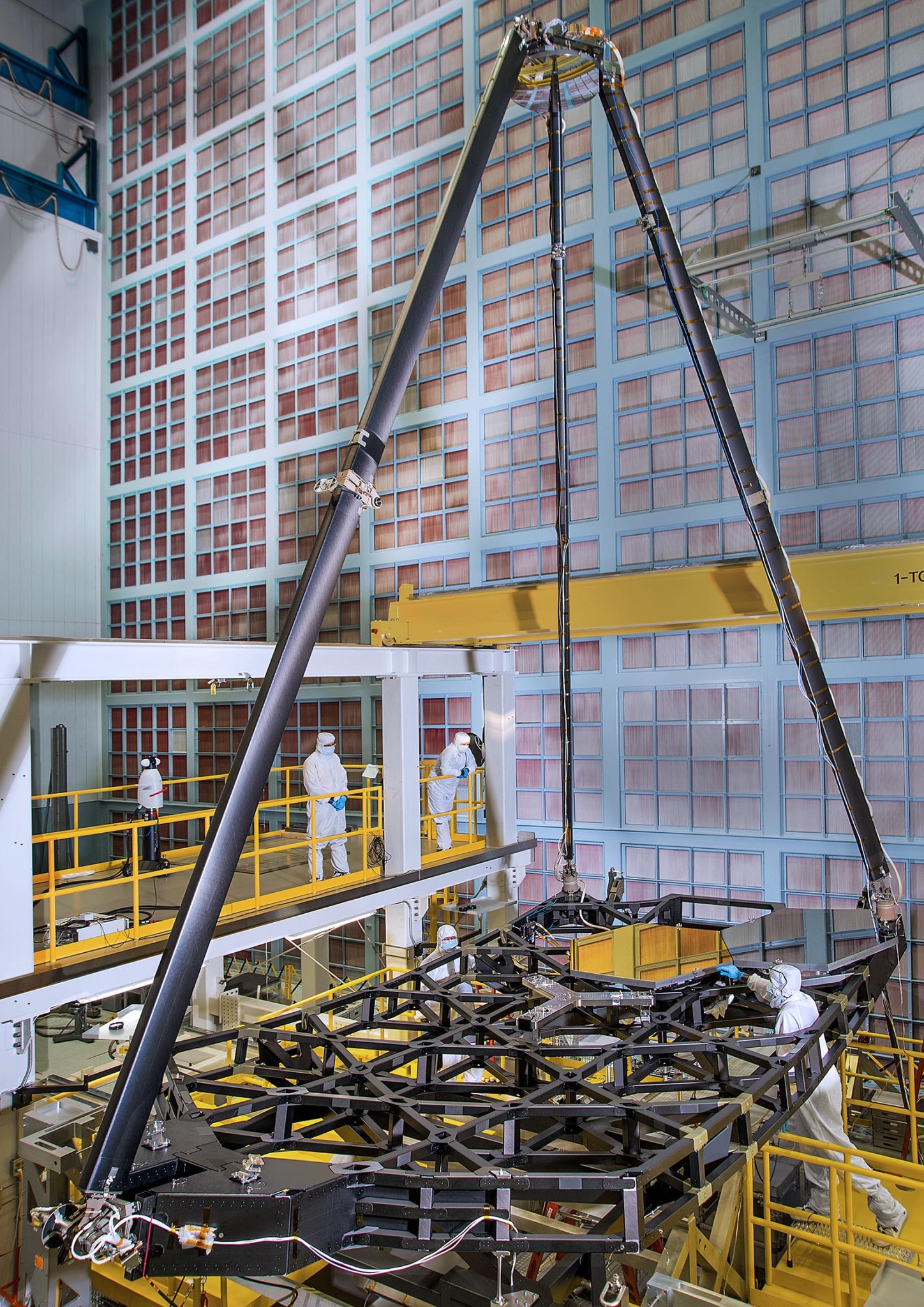

High Bay Clean Room

Before most Goddard spacecraft components are cleared for launch, they go through final checkups in one of the center’s many clean room facilities. The largest – with a massive 1.3 million cubic feet of space – is the High Bay Clean Room.

The High Bay Clean Room, often called the world’s largest, prevents dirt, dust and other contaminants from damaging spacecraft components, especially sensitive and carefully calibrated instruments. For example, unlike personal digital cameras, a smudge or speck of dust on the lens of a space telescope is extremely difficult – if not impossible – to clean, especially once the spacecraft reaches orbit a few hundred (or thousand, or million…) miles away.

A robust ventilation system and an entire wall of air filters help protect against these contaminants. The clean room ventilation system circulates almost one million cubic feet of air every minute through 9,000 square feet of HEPA filters located along one wall. The filters are not your typical off-the-shelf HEPA variety from the local home improvement store. These are specially designed to last several decades.

The High Bay Clean Room has been in use since the early 1990s. During the shuttle program, the facility could house two full space shuttle payloads at the same time. For many years this clean room housed sophisticated replicas of Hubble Space Telescope components. Now the High Bay Clean Room hosts pieces of Hubble’s upcoming successor, the James Webb Space Telescope.

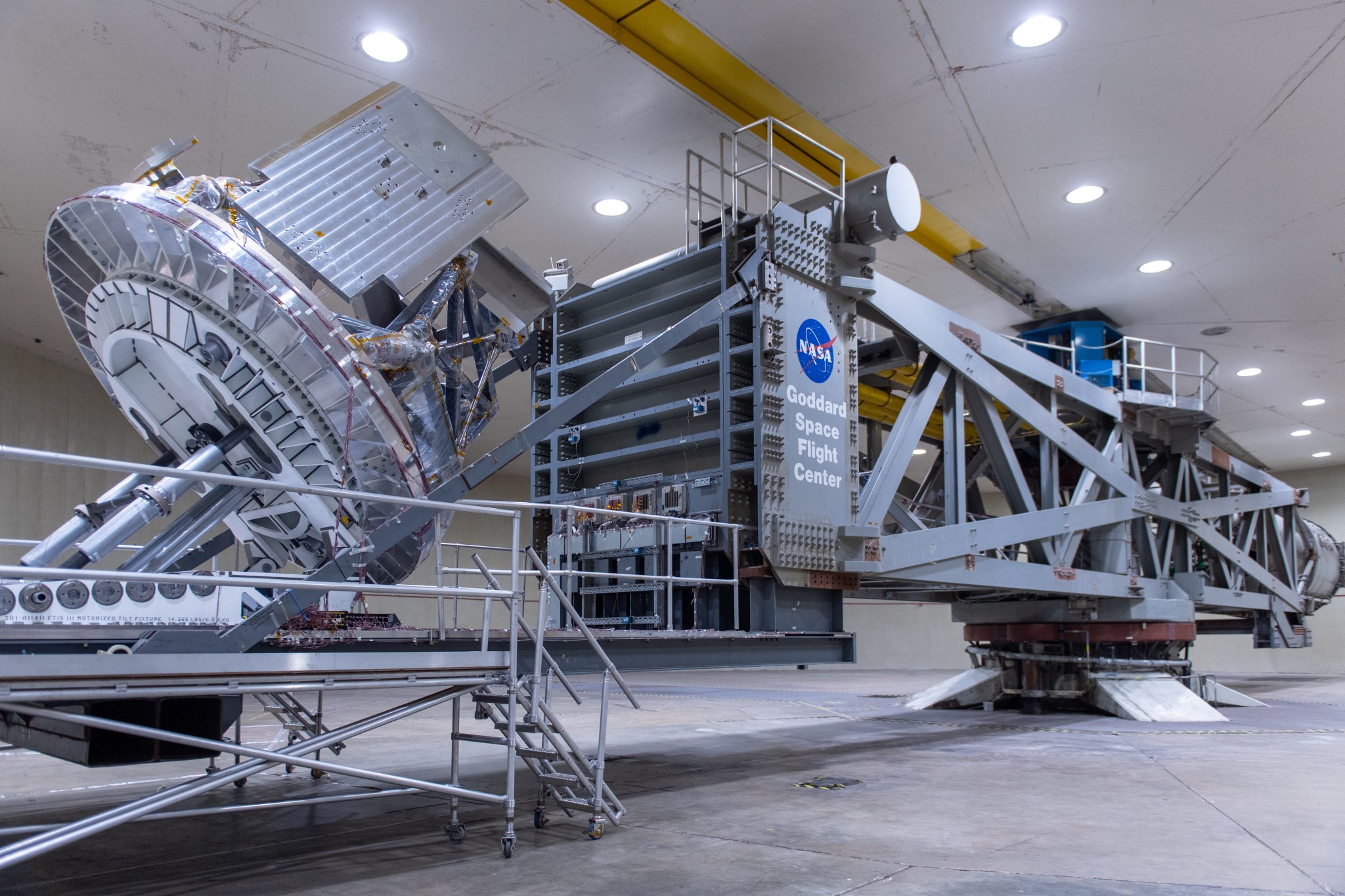

High-Capacity Centrifuge

The centrifuge simulates the increased feeling of gravity’s pull during a launch. For astronauts, that’s normally a few minutes at two or three times the force of Earth’s gravity, measured in Gs. Equipment carried in space shuttle cargo bays usually sees between 6 and 7 Gs because of vibration. (The most intense roller-coasters in the world top out at about 5 Gs, and then only for brief moments.)

Goddard’s 120-foot-diameter centrifuge can accelerate a 2.5-ton payload up to 30 Gs, well beyond the force experienced in a launch. Engineers decide how much force to use in a test, and they usually settle on a figure about 25 percent higher than what they expect the equipment will go through during launch. Instruments should be able to handle actual conditions if they hold up to the increased, simulated experience. Two 1,250-horsepower motors help the centrifuge produce that experience. Goddard’s centrifuge is only used to test instruments or equipment; no humans allowed.

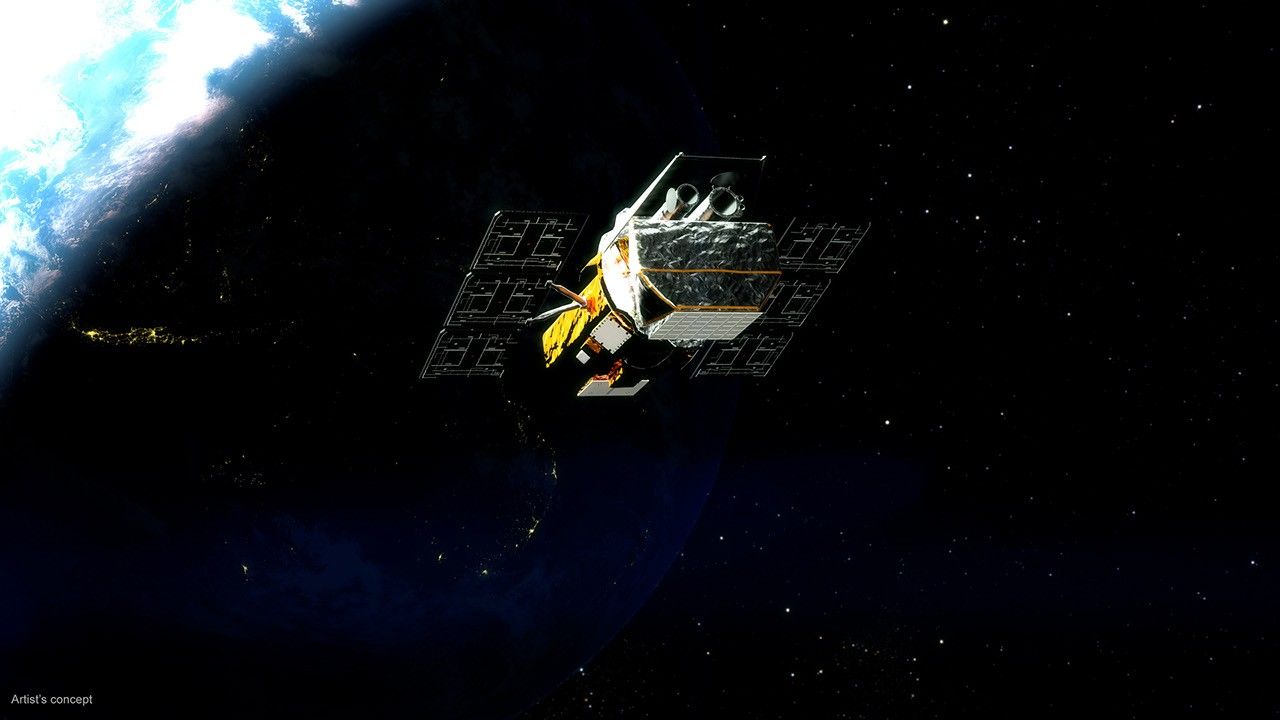

Hubble Space Telescope Operations Control Center

The Hubble Space Telescope has logged millions of miles and taken thousands of pictures since its launch in 1990, thanks in part to the around-the-clock efforts of dedicated engineers and technicians at Goddard’s Space Telescope Operations Control Center.

It’s up to mission operations staff to upload the commands to Hubble that tell it where to point and when, what sensing instruments to use, and when to send data back to Earth. They also troubleshoot any problems that may arise. To help the staff stay on top of telescope operations, Hubble transmits engineering data back to the command center at Goddard. That data contains information on how the telescope is functioning.

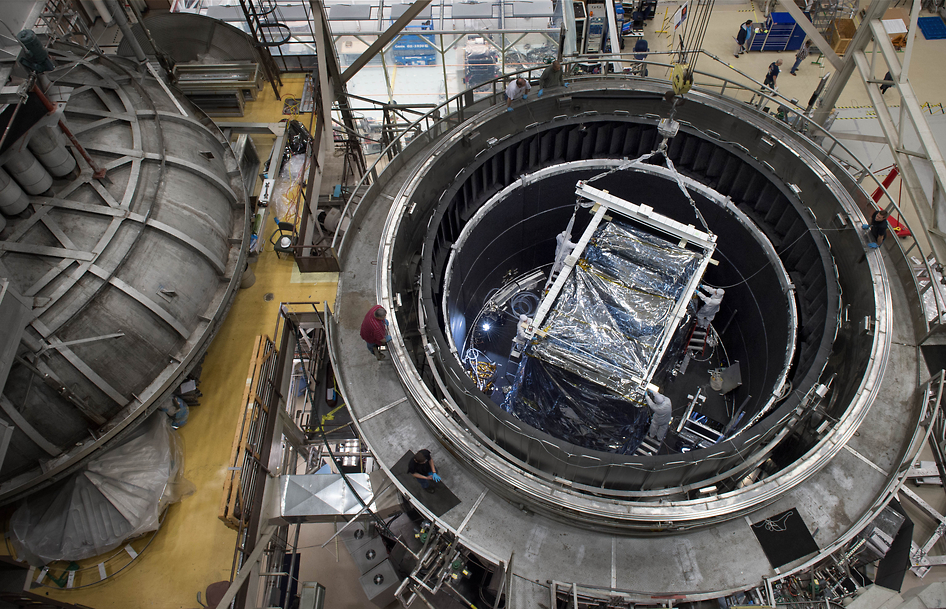

Space Environment Simulator

This thermal vacuum chamber exposes spacecraft components and other payloads to the environmental conditions they will experience once in space. The chamber has massive mechanical vacuum pumps, which are essentially large versions of the vacuum cleaners people use at home. To augment those, the chamber uses cryopumps to ensure that the hard vacuum of space is simulated in the test chamber. The cryopumps use liquid nitrogen to condense remaining gases out of the chamber once the mechanical pumps have done their work.

The two types of pumps work together to eliminate all but the tiniest trace of air in the chamber, down to about a billionth of Earth’s normal atmospheric pressure.

To simulate the hot and cold extremes possible in space, the thermal vacuum chamber can reach temperatures in a 600-degree range from 302 F all the way down to minus 310 F. The cylindrical chamber is 40 feet tall and 27 feet wide.

Scientific Visualization Studio

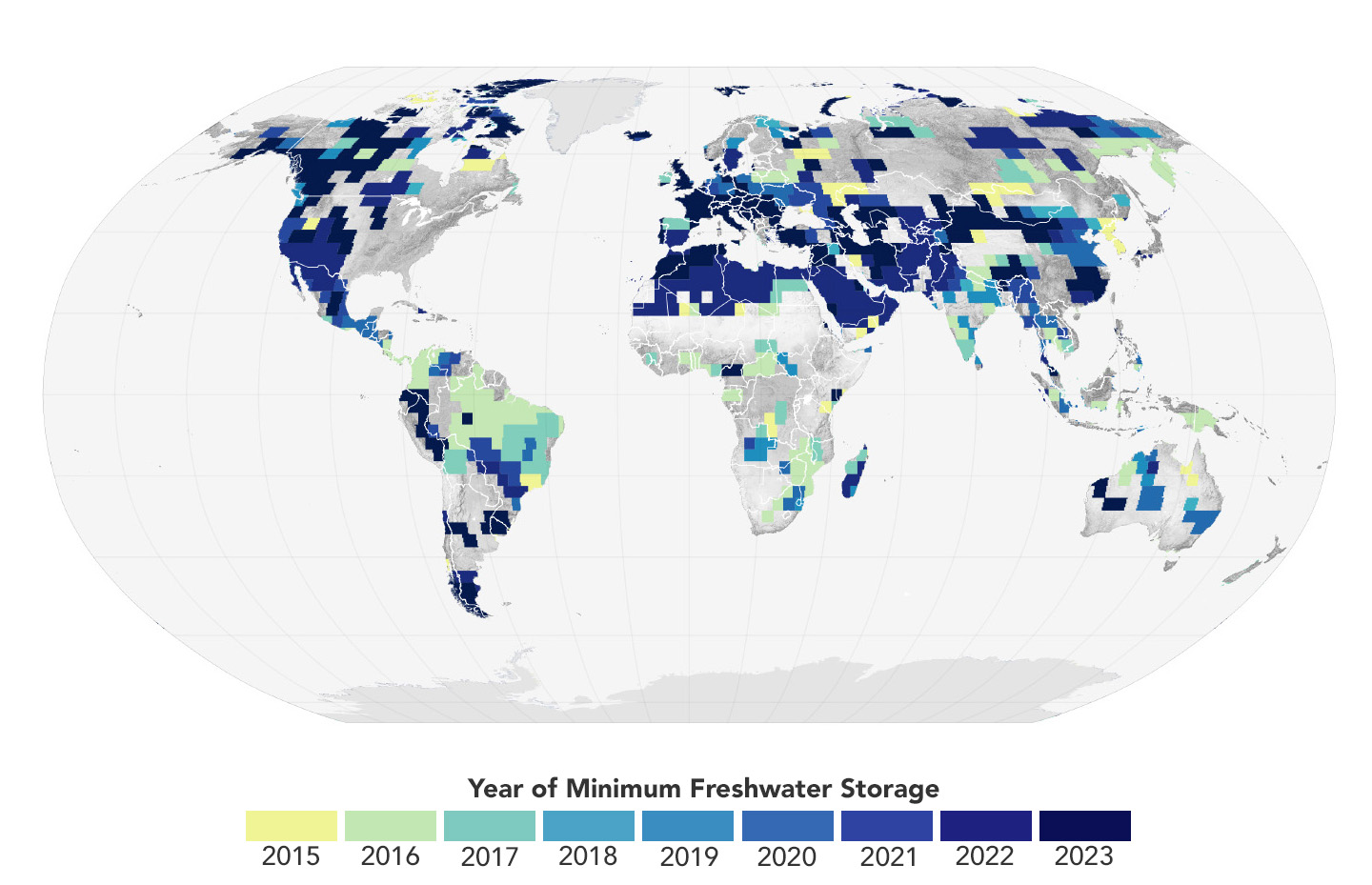

The Scientific Visualization Studio fosters scientific inquiry and outreach within NASA programs through visualizations (animations and artistic concepts based on scientific data). To that end, the SVS works closely with scientists in order to promote a greater understanding of Earth and space science.

All the visualizations created by the SVS (more than 2,900) are accessible to the public. More recent animations are provided as MPEG-4s, MPEG-2s and MPEG-1s. Most animations are available in high definition as well as NTSC format. Where possible, the original digital images used to make these animations have been made accessible. Lastly, high- and low-resolution stills, created from the visualizations, are included, with previews for selective downloading.