Bonnie Dunbar

Texas A&M

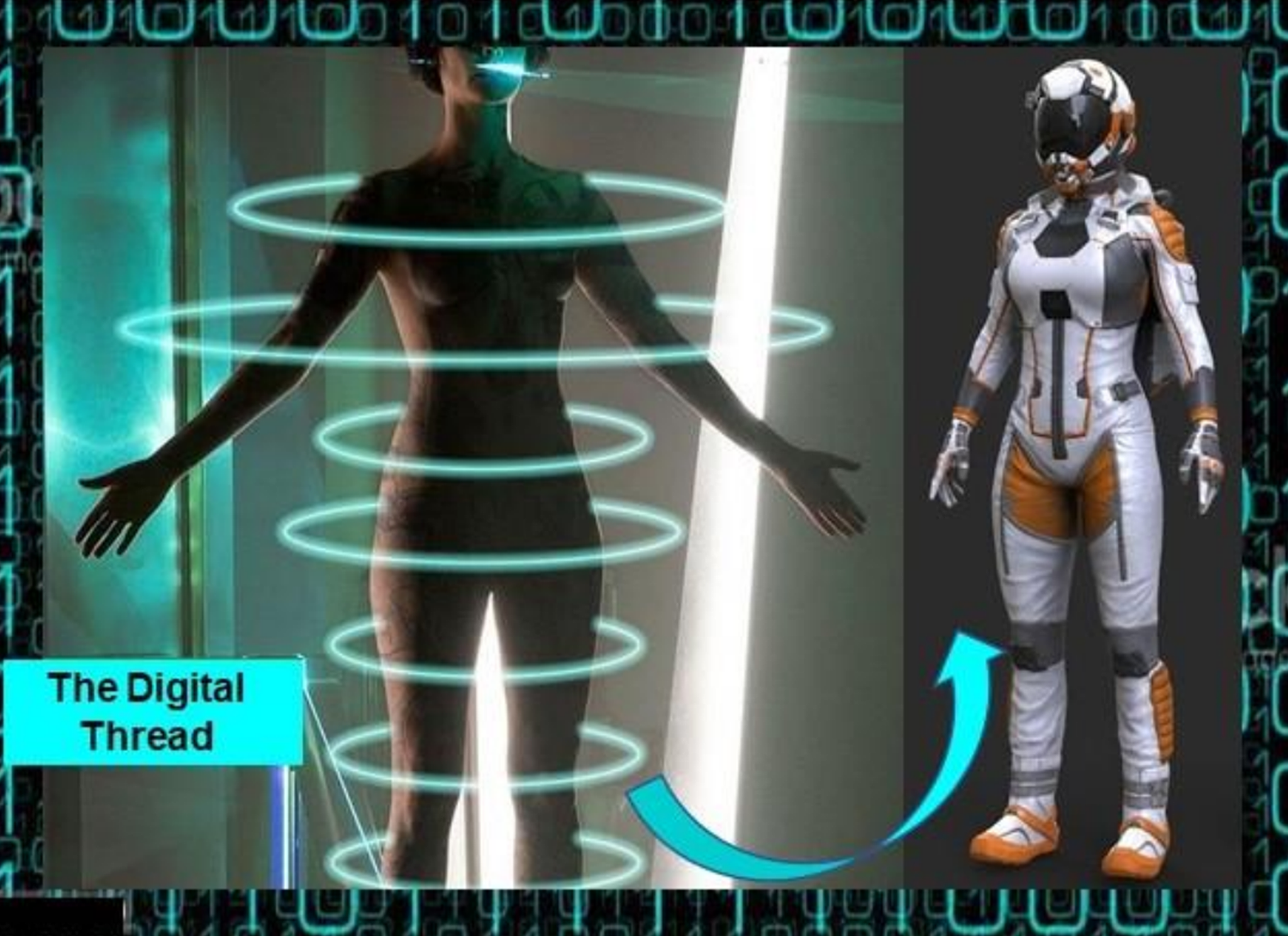

This proposal seeks to investigate the feasibility of manufacturing “custom” cost-effective high performance exploration spacesuits for Mars and beyond utilizing the Digital Thread (DT), which integrates digital analytic components for manufacturing in development of the final Spacesuit. The vision is a “digital human scan to digital design/analyses to robotic manufacture”. This approach would address several problems facing deep space travel, in particular: 1) the ability to rapidly design and manufacture Extravehicular Activity (EVA) space suits which are best suited to the anthropometrics of the individual crewmember (male and female) in any gravitational environment; 2) the need to build digital twins which are continually modified based on lessons learned and design optimization, 3) the ability for crew in deep space to manufacture or repair some EVA suit components in-situ based on digital files, and 4) the ability to digitally incorporate the EVA suit into the entire Mars Mission Architecture and Concept of Operations, including resupply, in-situ repair and fabrication and the repurposing of in-situ materials. The planned Mars architectures for placing humans on the surface in the 2030’s envisions nearly daily spacewalks in EVA suits. EVA suits are considered to be anthropometrically shaped “space ships” which must protect the crew from the extreme environments of space, while at the same time, providing the mobility required to effectively perform both engineering and scientific exploration tasks outside of the habitat or the spacecraft. Soft fabric “custom” suits were manufactured for all early spaceflight crewmembers (Mercury, Gemini, Apollo and Skylab) prior to the Space Shuttle Program. Apollo era crewmembers reported to be very satisfied with their custom suits, including those on the last mission, Apollo 17. To support the Space Shuttle Program, a “modular” plug and play suit, the Extravehicular Mobility Unit (EMU) was designed. The initial inventory included 5 Hard Upper Torso (HUT) chest sizes, 1 size helmet, adjustable arm and leg lengths but only two diameters, two size boots with adjustable inserts, and custom gloves. A total of 18 suits were built to support nearly 200 astronauts. For a variety of reasons, not all selected and trained astronauts could fit into or function in the suit, and many crewmembers experienced shoulder injuries, pressure points, finger nail loss, and nearly a 50% loss of effective strength due to the pressure resistance of the suit. A return to custom EVA suits seems warranted. But how to do this in a rapid cost effective manner? Is it possible to utilize current scanning technologies, human factor studies, physiological data, additive manufacturing, robotics, and modern digital design and analysis tools? The primary aim of this feasibility project is to answer to those questions by determining how the “Digital Thread” manufacturing process, which is being deployed in other non-human manufacturing spheres, can be used to develop a digital manufacturing stream which will provide any sized or shaped crewmember (or future tourist) with an optimized EVA space suit. The study will identify all key components of a spacesuit and current manufacturing technologies; map those to DT components; identify technology gaps; benchmark required technologies and capabilities in industry, academia and government; and develop a conceptional DT model for future Spacesuit Development and operational support. The digital thread could also include components to model suits in any given planetary environment and to model logistical requirements (supply and consumables). Example digital technologies/components which will be evaluated include 3D-Additive Manufacturing, human body IR/Photogrammetric scanning, digital twins, Computer Aided Design, model based engineering, human factors/kinematics models, and robotic/automated 3D garment manufacturing.