Microbiology

Contents

Introduction

The Johnson Space Center (JSC), a world leader in human spaceflight, possesses unique knowledge, skills, and capabilities that can be applied to solving human health and performance challenges, particularly those related to operating in extreme and harsh environments. NASA expertise is available in the areas of environmental monitoring, analysis, operational and hardware requirements development, design & implementation, verification/validation and monitoring, analysis, and data assessment. From technology development to integrated testing of human-system interfaces, human performance, system concepts, and mission operations, JSC provides unique microbiology expertise to ensure environmental standards and crew health and safety are achieved for human spaceflight.

The JSC Microbiology Community is concerned with addressing issues related to infectious disease, microbial ecology of spacecraft, and effects on crew health. This community is comprised of an integrated team of certified medical technologists, environmental microbiologists, immunologists, industrial hygienists, industrial microbiologists, mycologists, and biosafety professionals. The laboratory processes environmental samples (such as air, potable water, spacecraft surfaces, in-flight hardware, and food) to ensure that microorganisms do not adversely affect crew health or system performance. NASA expertise is available in the Environmental Chemistry Lab specializing in delivering high-quality analytical data relevant to chemicals that may be present in spaceflight air, water, or food samples. We invite our partners to leverage our capabilities in microbiology to ensure crew health on their own spacecraft and missions.

Capabilities

Microbiology Laboratory

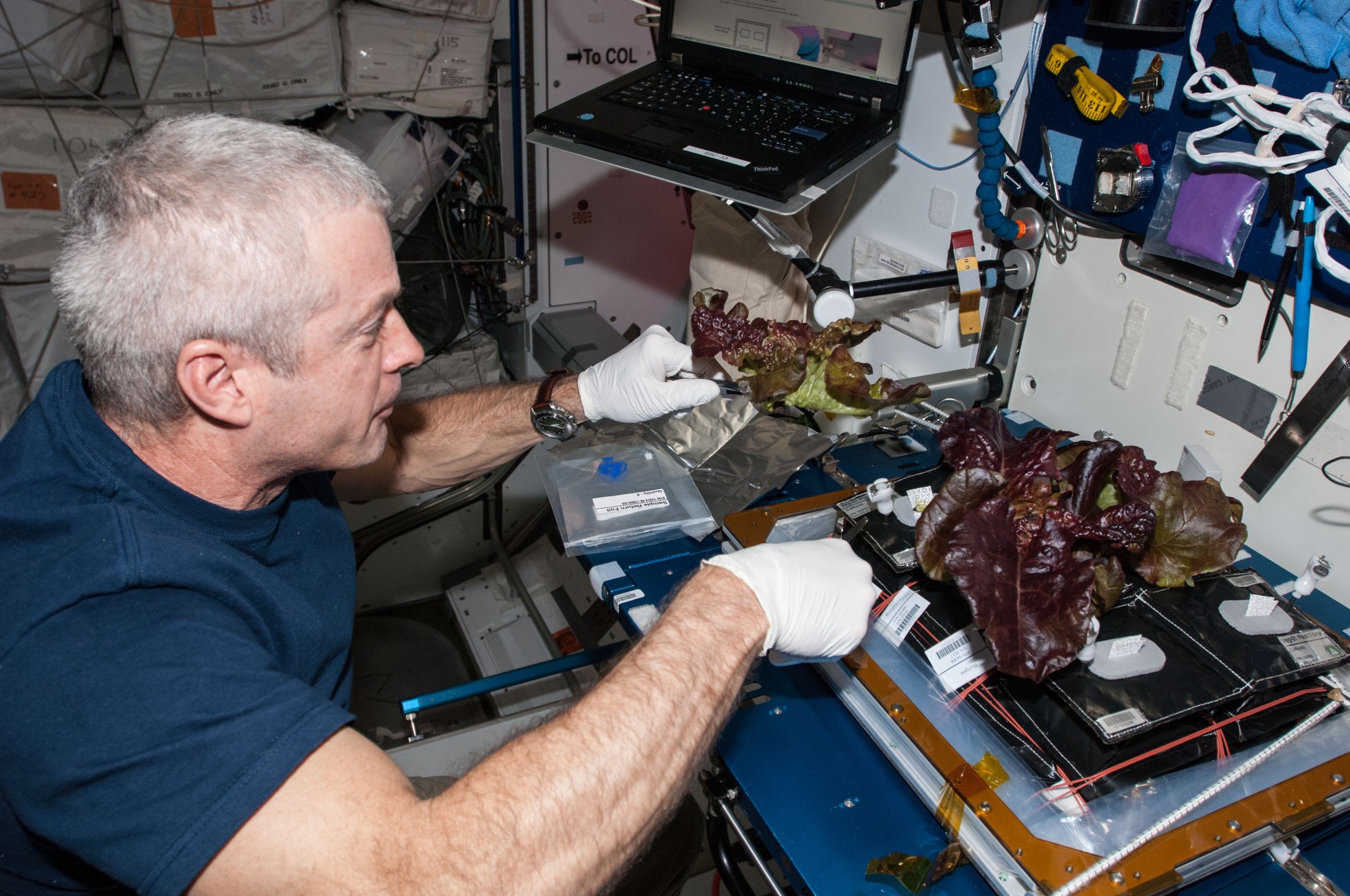

Overview | Microbiology Laboratory personnel at the Johnson Space Center are concerned with microbiological issues associated with crew health and the integrity of the spacecraft and its systems. The laboratory is comprised of an integrated team of environmental microbiologists, industrial microbiologists, molecular microbiologists, medical technologists, mycologists, and biosafety professionals, who advance spaceflight operations, basic and applied research, and technology development.

Details | The Microbiology Laboratory is a biosafety level 2 facility accredited by The American Industrial Hygiene Association and the National Environmental Laboratory Accreditation Program.

- Classical bacteriology and mycology, advanced molecular sequencing techniques, and host-pathogen interaction studies

- Collect microbial analysis of environmental samples (air, water and surface) and spaceflight food

- Develop microbial contamination standards and requirements

- Perform custom microbial testing

- Develop prototype flight hardware and microgravity compatible protocols for molecular sequencing (i.e., MinION)

Precision Clean Room

Overview | NASA JSC Class 1000 Precision Clean Room provides standard processes for cleaning materials used in critical space applications.

Details |

- Precision cleaning processes include visibly clean (VC), VC Ultraviolet, and VC Highly Sensitive

- Precision levels from 50 – 1000

- Particle count verification with deionized (DI) water or hydrofluoroethers (HFE) rinse

- Rinse solution is strained and filtered for particle count and size

- Ovens dry parts before bagging and tagging

Precision Cleaning

Overview | White Sands Test Facility (WSTF) provides contamination control support to its customers through cleaning and cleanliness verification, personal protection equipment, and clean room garments maintenance. The Contamination Control Laboratory provides standard processes for cleaning materials used in critical space applications and performs special processes including pickling and passivation.

Details | The Contamination Control Laboratory at White Sands Test Facility (WSTF) provides standard processes for cleaning materials used in critical space applications. Some of the construction materials are titanium, stainless steel, aluminum, brass, and various plastics, and elastomers. Cleanliness is verified using a variety of fluids, including isopropyl alcohol, ultra-pure water, and hydrofluoro ether (HFE 7100) for a multitude of systems including oxygen, hypergolics, and nitrogen. Precision cleaned items are packaged in clean nylon or Teflon® bags, with an outer bag of polyethylene to protect the cleanliness of the hardware until ready for use. Special processes including pickling and passivation are also performed in the Contamination Control Laboratory. Among items processed through this laboratory are man-rated breathing apparatus for space flight, lubrication systems on large vacuum pumps, large oxygen tanks, and tube-bank trailers. Personal protective equipment (PPE) at WSTF is a critical part of testing aerospace hardware and systems. We test, maintain, and certify self-contained breathing apparatus (SCBA), totally encapsulating suits (TES) and standard splash gear. WSTF operates a clean room garment processing facility that cleans, samples, and packages uniforms for use in critical clean areas.

Spaceflight Component Processing

Overview | White Sands Test Facility (WSTF) Spaceflight Component Services Group provides support for flight, flight-like, and critical test components through fabrication, repair, refurbishment, acceptance testing, failure analysis, and decontamination processes.

Details |

Component/Test Article Decontamination Areas

- Two laboratory fume extraction hoods (one for fuel propellant & one for oxidizer propellant contaminated hardware)

- Three ISO 7 (Class 10,000) decontamination clean rooms with propellant vapor fume extractor systems for handling fuel & oxidizer propellant contaminated hardware

- Heated GN2 purge/drying system

- Deionized Water supply systems

- Portable deionized water pump/circulation system

- Portable process water catch/pump transfer system

Component Repair, Refurbishment, & Acceptance Testing

- Technical expertise in the processing of development, qualification, and flight hardware

- Personnel with hands-on experience in the processing (decontamination, failure analysis, disassembly, reassembly, repair, acceptance testing) of flight hardware ranging from Space Shuttle and International Space Station to other commercial vendor hardware

- Mono and hypergolic propellant & oxygen system expertise

- Test system design, fabrication, and operation

- Experience in the development of detailed processing & test procedures

- Borescope and microscope inspection equipment with digital recording capability

Flight Hardware Parts & Component Fabrication/Manufacturing

- Certified to manufacture flight hardware

- Foreign Object Debris (FOD) awareness training

- Technicians certified to IPC J-STD-001FS Space Applications Electronic Hardware Addendum to IPC J-STD-001F Requirements for Soldered Electrical and Electronic Assemblies

- NASA Standard STD-8739.1, Workmanship Standard for Polymeric Application on Electronic Assemblies

- NASA Standard STD-8739.4, Workmanship Standard for Crimping, Interconnecting Cables, Harnesses, and Wiring

- NFPA 70 National Electrical Code & NFPA 70E Standard for Electrical Safety in the Workplace

Bonded Storage Facility

- Procedures & systems in place for the controlled storage of critical hardware

White Sands Test Facility (WSTF) Cleanrooms

Overview | White Sands Test Facility (WSTF) maintains several clean rooms and large areas that can be used for test article assembly and checkout. These areas range from Class 100 clean rooms and flow benches to large size assembly areas.

Details |

ISO 5 (Class 100) Clean Rooms

- A 20 x 24 x 8 ft3 clean room with a 6 x 12 ft2 anteroom is used for processing flight hardware

- Precision cleaned hardware is processed in a 26 x 24 x 8 ft3 clean room

- Components are reassembled, and function tested in a 14 x 21 x 8 ft3 clean room

- WSTF uses several Class 100 laminar flow benches, each equipped with varying levels of facility supply including nitrogen, helium, oxygen, and compressed air

ISO 7 (Class 10,000) Clean Rooms

- A 20 x 20 x 15 ft3 assembly room is equipped with facility 3000-psi nitrogen and helium with the ability to supply up to 9000 psi

- The Spaceflight Component Services Area has several different soft-walled ISO 7 (Class 10,000) work areas currently configured for decontaminating hardware with some limited functional and leak testing capabilities

- A 15 x 15 ft soft-walled structure used to provide a local class 10,000 work environment

- All clean room garments are processed in a soft-walled Class 10,000 work area

Available Clean Rooms, Test & Assembly Areas, & Special Equipment

- One ISO 5 (Class 100) & four ISO 7 (Class 10,000) clean rooms (hard & soft wall) ranging from 100 to 600 ft

- Six Class 100 laminar flow bench work areas

- Building 416 is an environmentally controlled 60 x 40 x 22 ft facility with a moveable 16 x 16 x 10 ft Class 100,000 soft walled work area

- Various inert gas (gaseous nitrogen – GN2, gaseous helium – GHe) & fluid test systems (deionized water) available

- Borescope and microscope inspection equipment with digital recording capability

- Fabrication & Assembly Area (Test Articles, Servicing Equipment, Test Panels)

- High-bay shop area – 1500 ft2 with 20-ft W x 45-ft H access door & overall work height

- Shop-air, breathing air, GN2, GHe, and deionized water supplies available

- 15-ton overhead bridge crane and 1/4-ton motorized Coffing crane