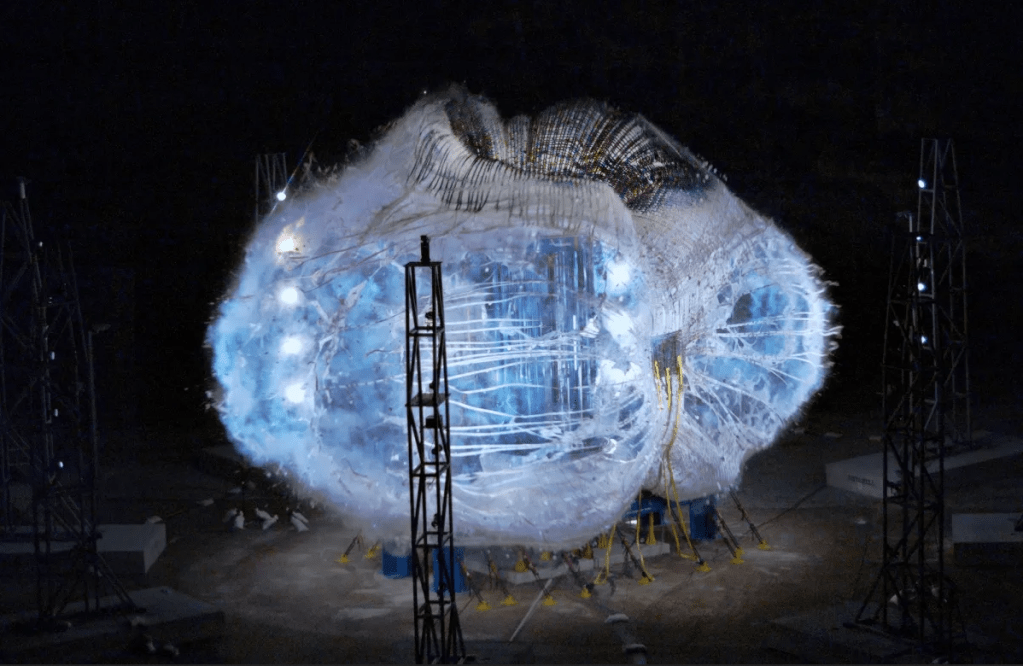

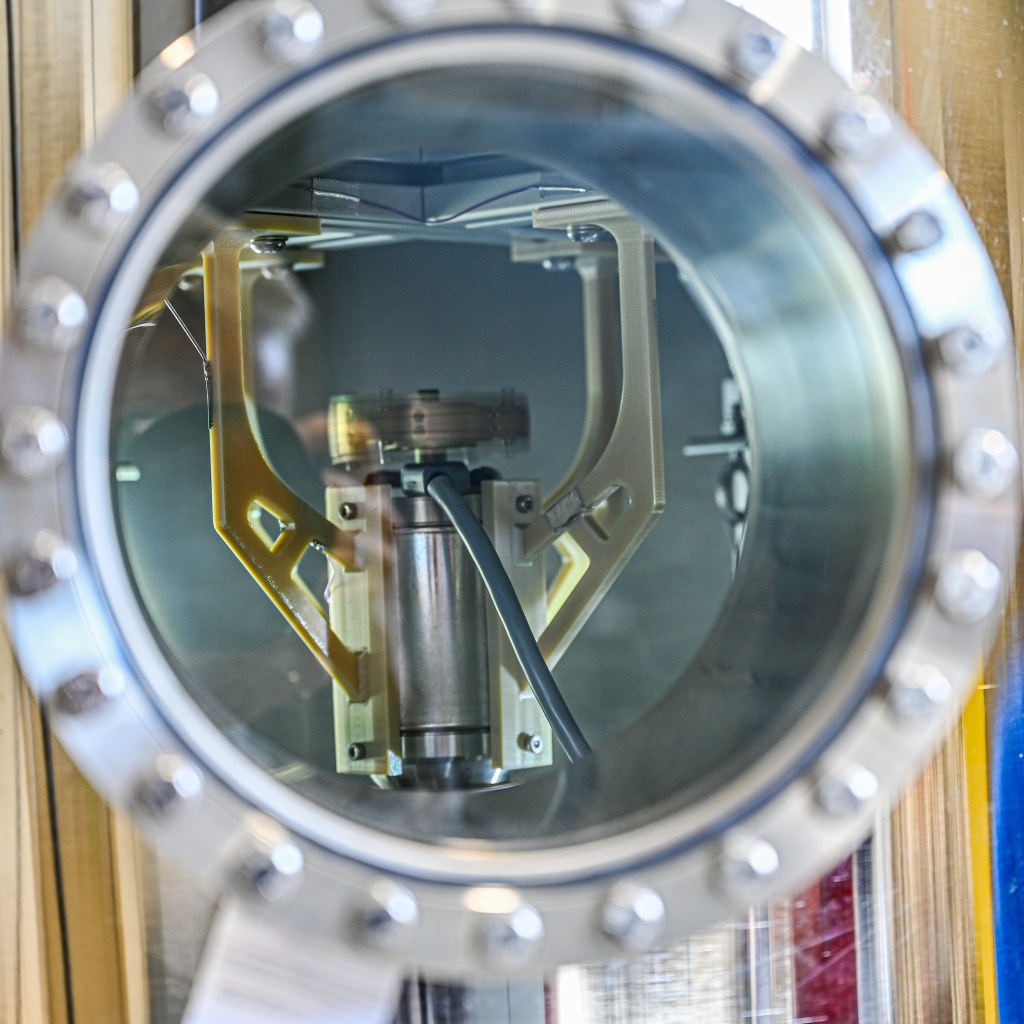

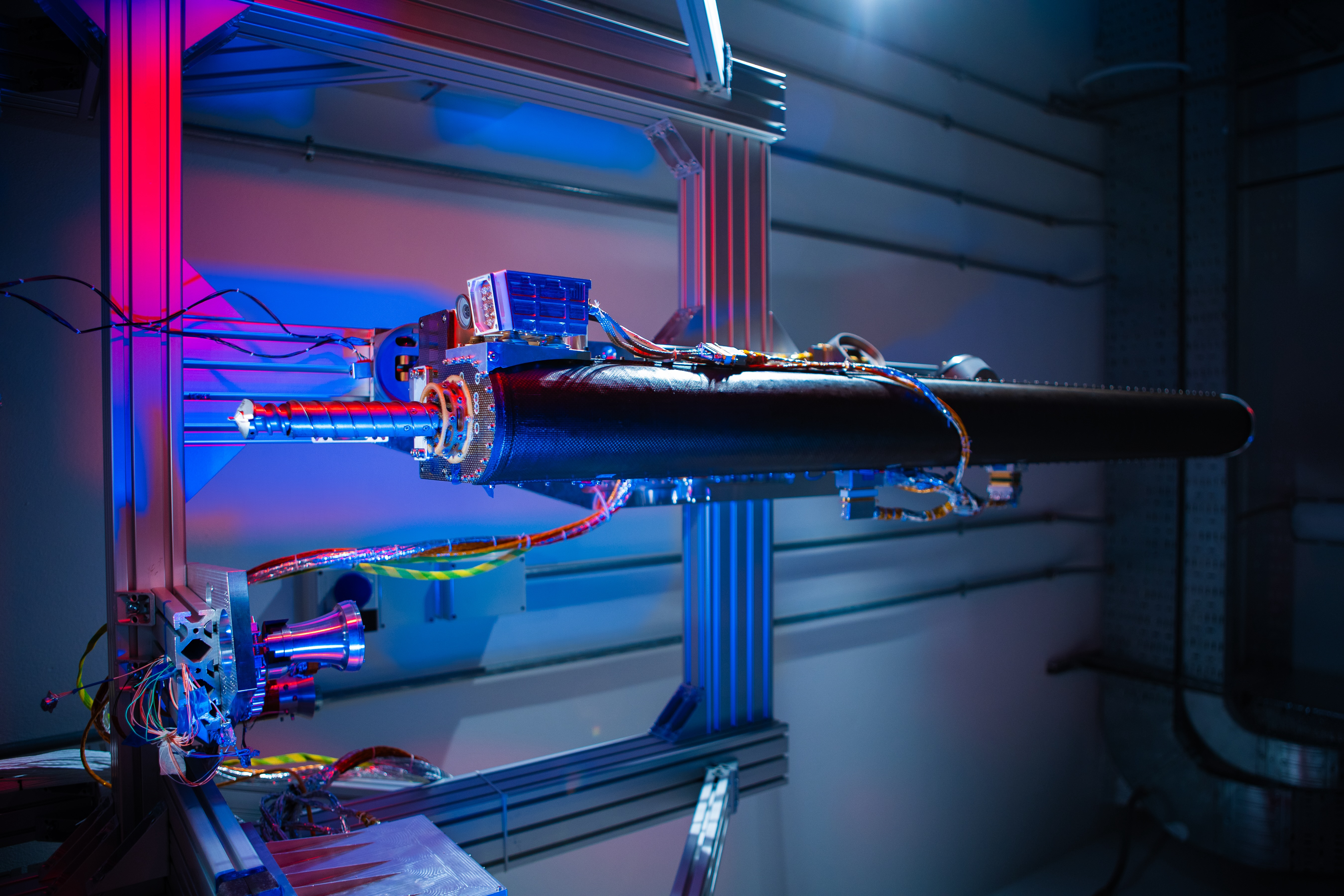

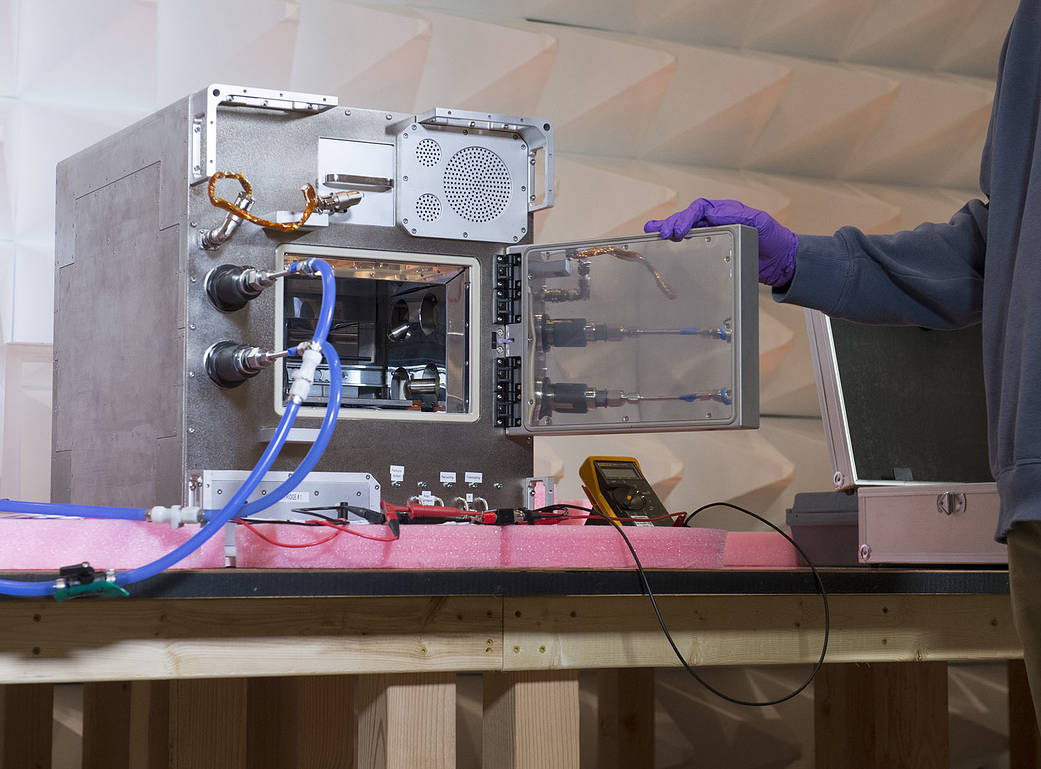

The first integrated 3D printer and recycler is part of the cargo that was launched to the International Space Station on Northrop Grumman’s Cygnus spacecraft’s 10th commercial resupply services mission. The machine, known as Refabricator, will demonstrate the capability to turn waste plastic and previously 3D printed parts into high-quality 3D printer filament (3D printing “ink”) to create new tools and materials. The demonstration will use control plastic recycled multiple times to create parts that will be tested for quality back on Earth.

This technology could prove useful for future exploration missions to the Moon and Mars. NASA awarded a Small Business Innovation Research contract to Tethers Unlimited Inc. of Seattle to build Refabricator. The unit completed final flight certification testing at NASA’s Marshall Space Flight Center in Huntsville, Alabama. Almost all operations will be controlled remotely from Marshall’s Payload Operations Integration Center – mission control for science on the space station – and Tethers Unlimited Inc.

Refabricator is among several tons of cargo, including crew supplies and science experiments, that launched on Northrop Grumman’s Cygnus spacecraft on an Antares rocket Nov. 17 at 4:01 a.m. from NASA’s Wallops Flight Facility on Virginia’s Eastern Shore.

For more on Refabricator, visit: https://www.nasa.gov/mission_pages/centers/marshall/images/refabricator.html.

For Northrop Grumman commercial resupply mission updates, visit: https://www.nasa.gov/northropgrumman

Image: NASA/Emmett Given