Imagine you just moved to the surface of the Moon. There is plenty of available real estate, and you pick a nice-looking plot, away from craters and burnt-out volcanoes, for your home. You begin building on the powdery surface, first putting up walls, and then using a device like an inkjet printer to print solar cells that will generate your electricity. Once you finish, you step inside, turn out the lights and close the blinds to block the Sun that won’t set for another 14 Earth days.

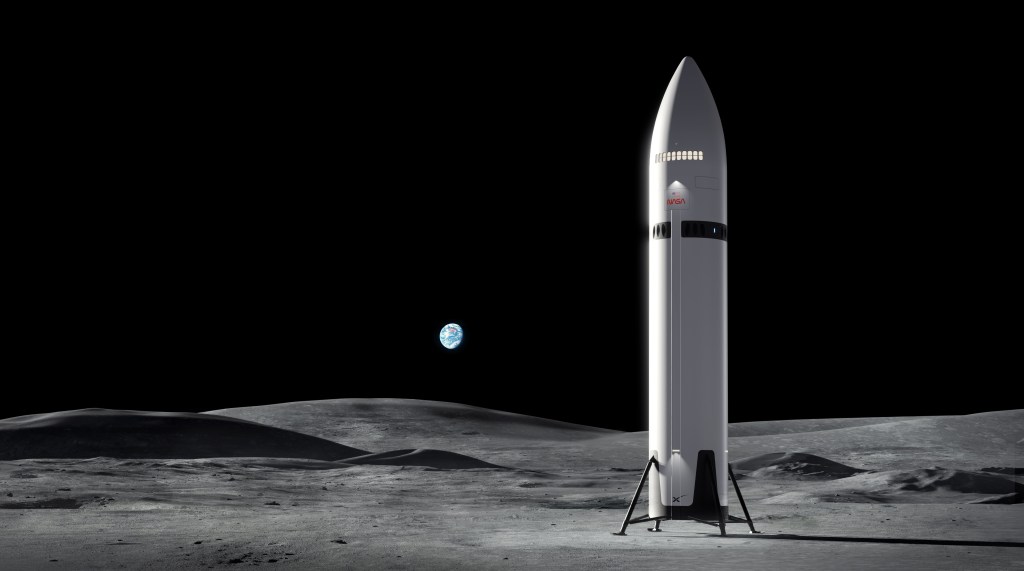

In the future, this imaginary scene could become reality. With the Artemis program, the first woman and next man will step foot on the Moon by 2024, and NASA will establish sustainable exploration with commercial and international partners by 2028. The long-term goal is to use what we learn on the Moon to prepare for the next giant leap — sending astronauts to Mars.

It’s an ambitious mission—creating an environment that allows us to have a long-term presence on another world is not an easy task. But scientists at NASA’s Glenn Research Center in Cleveland are developing new technology to make it possible, beginning with the solar cells that could power lunar habitats.

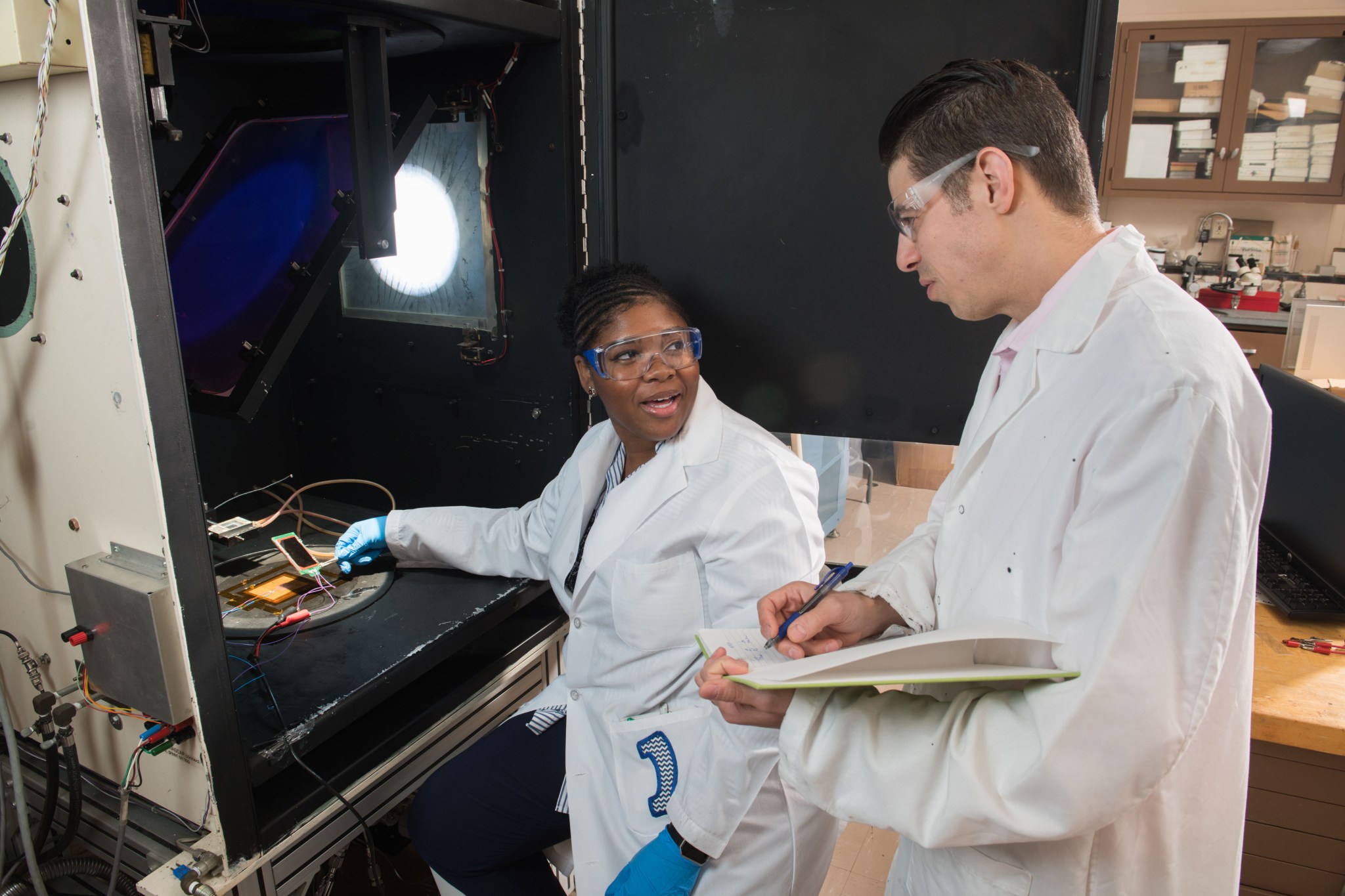

Engineers Lyndsey McMillon-Brown and Timothy Peshek are leading a project to test perovskite solar cells, which could be an alternative to silicon solar cells currently used in space. This material is a relatively new discovery, and it has many advantages for solar technology. Not only is perovskite an incredible conductor of electricity, but it also can be transported into space as a liquid and then printed onto panels on the Moon or Mars, unlike silicon panels that have to be built on Earth and then shipped to space.

“It’s a build as you go process,” said McMillon-Brown. “Perovskites have a nice versatility we haven’t yet seen. In a short period, there have been rapid advancements in its efficiencies and its behavior. We’ve seen a lot of growth in this field.”

With just one liter of the solution, astronauts would have enough material to generate a megawatt of solar power, which is far more energy than is required to run the International Space Station. But the perovskite material is only part of what makes Glenn scientists so excited for the potential of this project; the other is the new method for assembling solar cells called electrospraying that researchers at the University of California at Merced developed.

Electrospraying works like an inkjet printer, and it makes assembly quick, easy and efficient. It requires a small nozzle to deposit the perovskite solution as a thin film—about 250 times thinner than a human hair—onto a substrate that acts as the structure for the panel.

“When you print solar cells in space, you don’t have to worry about the launch destroying the cells or its structure,” Peshek said. “Your efficiency is in the volume of space it takes up, and it’s condensed.”

Because perovskite is essentially a salt, its greatest downfall is its inability to handle moisture. This creates challenges for applications of the material on Earth, and many researchers are working to overcome this obstacle by encasing it in plastic. This weakness is a reason scientists are interested in testing perovskites in space. In environments like those of the Moon and Mars, moisture is not a concern.

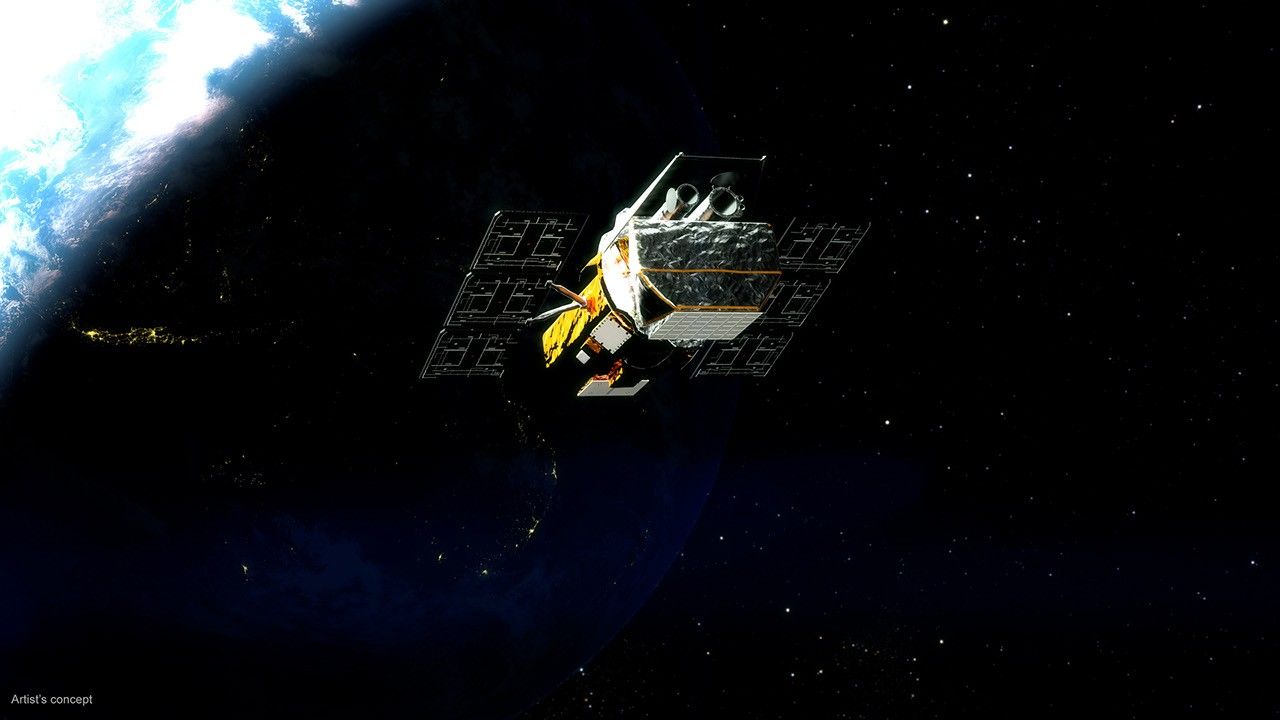

With the research still in its early stages, there are still many unknowns, but Glenn’s scientists are beginning test flights to see how the material responds in harsh environments. The perovskites are scheduled to fly on the Materials International Space Station Experiment 13, and further testing will be conducted over the next two years.

“To be working on technology to print solar cells on the Moon while we’re working on a return mission to the Moon is really exciting,” McMillon-Brown said. “If this project goes well in the next two years, there might actually be space for us to demonstrate this on the Moon in the next four to eight years. It’s very real. And it’s very possible.”

Katherine Herrick

NASA’s Glenn Research Center