Lighter, faster, more efficient. Whenever you advance a technology, that’s the goal. As NASA looks to transform the commercial aircraft of the future, efficient engines are at the heart of it all.

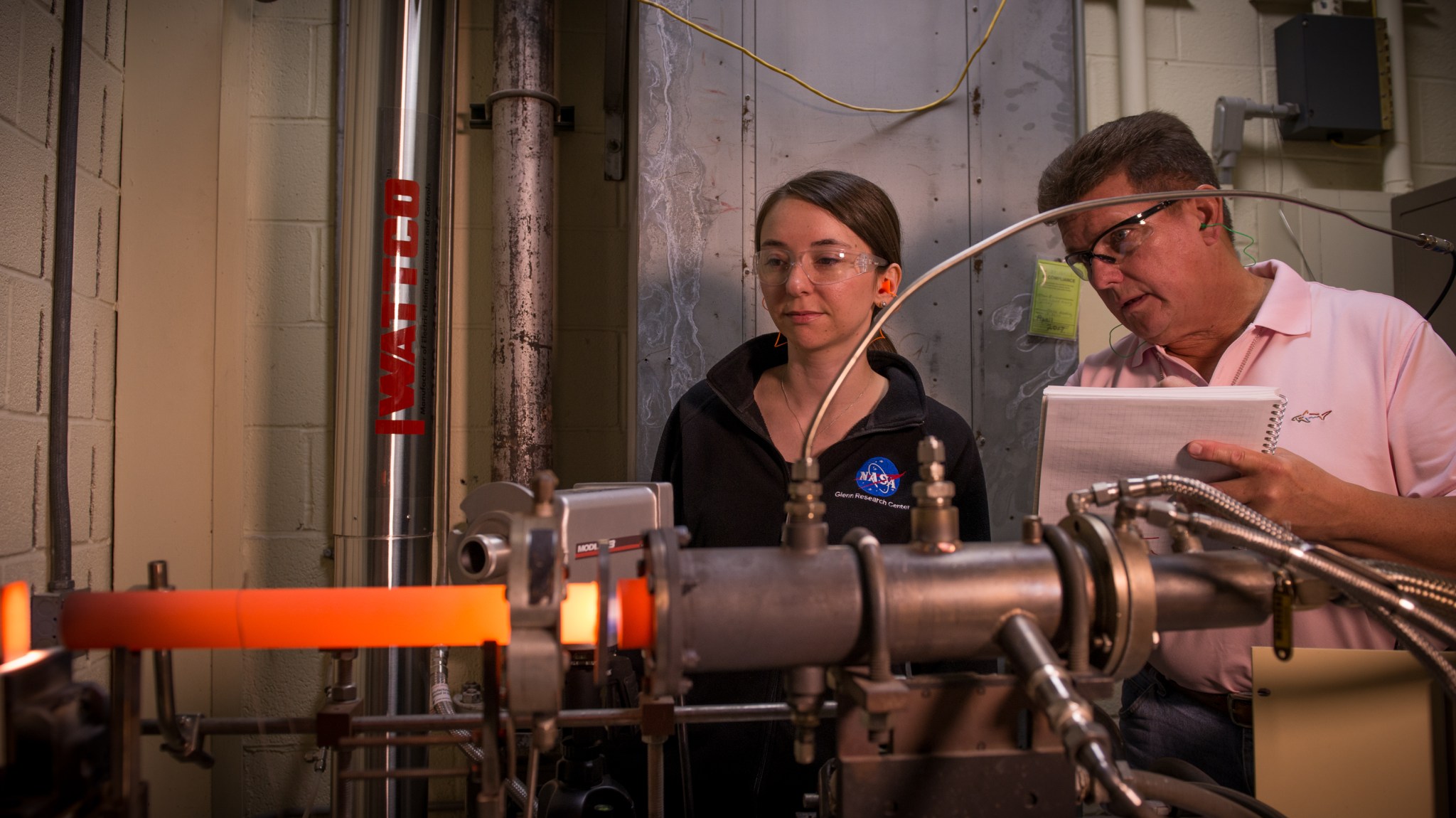

To achieve the goal of better engines on future aircraft, researchers at NASA Glenn are investigating promising advances in high-temperature materials that can be used to make turbine engine components.

These materials, called ceramic-matrix composites or CMCs, are lighter, stronger and can withstand the demanding forces of the extremely high temperatures generated in the core of jet engines. CMCs are in a position to replace the nickel-based super alloy metals in today’s aircraft engines.

In general, the hotter an engine runs, the better the fuel efficiency. Over the years, engines have been able to run hotter because metal parts were treated with thermal barrier coatings. But there is a limit to what the coatings can tolerate. CMCs, on the other hand, can withstand temperatures up to 2700˚ F and beyond with the help of specially designed ceramic coatings called environmental barrier coatings.

“We want to understand how CMCs and protective coatings can not only withstand high heat, but also environmental particle hazards such as dust, sand and volcanic ash,” says NASA Glenn Materials Engineer Valerie Wiesner. “This is important because, as aircraft engine temperatures increase to promote fuel efficiency, sand, when it’s ingested into an engine, can actually melt into glass and potentially cause power loss or failure.”

Moving next generation aircraft toward greater operating efficiency will depend, in large part, on advances in engine technology and materials manufacturing capabilities. NASA Glenn researchers are exploring the 3D printing and testing of complex materials like CMCs to see if they can withstand the high temperature environment of future aircraft engines.

This research is conducted in support of NASA’s Transformative Aeronautics Concepts Program.

Nancy Smith Kilkenny, ATS

NASA Glenn Research Center