The Space Shuttle

The world's first reusable spacecraft launched like a rocket, maneuvered in Earth orbit like a spacecraft and landed like an airplane. It was comprised of the orbiter, the main engines, the external tank, and the solid rocket boosters.

Shuttle Basics

Length

Space Shuttle: 184 feet

Orbiter: 122 feet

Height

Orbiter on runway: 57 feet

Wingspan

78 feet

Liftoff Weight*

4.5 million pounds

Orbit (Distance from Earth)

115 to 386 statute miles

Velocity

17,321 mph

* weight varied depending on payloads and on board consumables.

The Space Shuttle was the world’s first reusable spacecraft, and the first spacecraft in history that can carry large satellites both to and from orbit. The Shuttle launches like a rocket, maneuvers in Earth orbit like a spacecraft and lands like an airplane. Each of the three Space Shuttle orbiters now in operation—Discovery, Atlantis and Endeavour—is designed to fly at least 100 missions. So far, altogether they have flown a combined total of less than one-fourth of that.

Columbia was the first Space Shuttle orbiter to be delivered to NASA’s Kennedy Space Center, Fla., in March 1979. Columbia and the STS-107 crew were lost Feb. 1, 2003, during re-entry. The Orbiter Challenger was delivered to KSC in July 1982 and was destroyed in an explosion during ascent in January 1986. Discovery was delivered in November 1983. Atlantis was delivered in April 1985. Endeavour was built as a replacement following the Challenger accident and was delivered to Florida in May 1991. An early Space Shuttle Orbiter, the Enterprise, never flew in space but was used for approach and landing tests at the Dryden Flight Research Center and several launch pad studies in the late 1970s.

The Space Shuttle consists of three major components: the Orbiter which houses the crew; a large External Tank that holds fuel for the main engines; and two Solid Rocket Boosters which provide most of the Shuttle’s lift during the first two minutes of flight. All of the components are reused except for the external fuel tank, which burns up in the atmosphere after each launch.

The longest the Shuttle has stayed in orbit on any single mission is 17.5 days on mission STS-80 in November 1996. Normally, missions may be planned for anywhere from five to 16 days in duration. The smallest crew ever to fly on the Shuttle numbered two people on the first few missions. The largest crew numbered eight people. Normally, crews may range in size from five to seven people. The Shuttle is designed to reach orbits ranging from about 185 kilometers to 643 kilometers (115 statute miles to 400 statute miles) high.

The Shuttle has the most reliable launch record of any rocket now in operation. Since 1981, it has boosted more than 1.36 million kilograms (3 million pounds) of cargo into orbit. More than than 600 crew members have flown on its missions. Although it has been in operation for almost 20 years, the Shuttle has continually evolved and is significantly different today than when it first was launched. NASA has made literally thousands of major and minor modifications to the original design that have made it safer, more reliable and more capable today than ever before.

Since 1992 alone, NASA has made engine and system improvements that are estimated to have tripled the safety of flying the Space Shuttle, and the number of problems experienced while a Space Shuttle is in flight has decreased by 70 percent. During the same period, the cost of operating the Shuttle has decreased by one and a quarter billion dollars annually—a reduction of more than 40 percent. At the same time, because of weight reductions and other improvements, the cargo the Shuttle can carry has increased by 7.3 metric tons (8 tons.)

In managing and operating the Space Shuttle, NASA holds the safety of the crew as its highest priority.

The Orbiter

Orbiter Stats

Height (on runway)

57 feet

Length

122 feet

Wingspan

78 feet

Midfuselage

Length: 60 feet

Width: 17 feet

Height: 13 feet

Aft Fuselage

Length: 18 feet

Width: 22 feet

Height: 20 feet

Payload Bay Doors

Length: 60 feet

Diameter: 15 feet

Width: 22.67 feet

Surface: 1,600 feet2

The Orbiter is both the brains and heart of the Space Transportation System. About the same size and weight as a DC-9 aircraft, the Orbiter contains the pressurized crew compartment (which can normally carry up to seven crew members), the huge cargo bay, and the three main engines mounted on its aft end.

The cockpit, living quarters and experiment operator’s station are located in the forward fuselage of the Orbiter vehicle. Payloads are carried in the mid-fuselage payload bay, and the Orbiter’s main engines and maneuvering thrusters are located in the aft fuselage.

Forward Fuselage

The cockpit, living quarters and experiment operator’s station are located in the forward fuselage. This area houses the pressurized crew module and provides support for the nose section, the nose gear and the nose gear wheel well and doors.

Crew Module

The 65.8-cubic-meter (2,325-cubic-foot) crew station module is a three-section pressurized working, living and stowage compartment in the forward portion of the Orbiter. It consists of the flight deck, the middeck/equipment bay and an airlock. Outside the aft bulkhead of the crew module in the payload bay, a docking module and a transfer tunnel with an adapter can be fitted to allow crew and equipment transfer for docking, Spacelab and extravehicular operations.

The two-level crew module has a forward flight deck with the commander’s seat positioned on the left and the pilot’s seat on the right.

Flight Deck

The flight deck is designed in the usual pilot/copilot arrangement, which permits the vehicle to be piloted from either seat and permits one-man emergency return. Each seat has manual flight controls, including rotation and translation hand controllers, rudder pedals and speed-brake controllers. The flight deck seats four. The on-orbit displays and controls are at the aft end of the flight deck/crew compartment. The displays and controls on the left are for operating the Orbiter, and those on the right are for operating and handling the payloads. More than 2,020 separate displays and controls are located on the flight deck.

Six pressure windshields, two overhead windows and two rear-viewing payload bay windows are located in the upper flight deck of the crew module, and a window is located in the crew entrance/exit hatch located in the midsection, or deck, of the crew module.

Middeck

The middeck contains provisions and stowage facilities for four crew sleep stations. Stowage for the lithium hydroxide canisters and other gear, the waste management system, the personal hygiene station and the work/dining table is also provided in the middeck.

Airlock

The airlock provides access for spacewalks, known as extravehicular activity, or EVA. It can be located in one of several places: inside the Orbiter crew module in the middeck area mounted to the aft bulkhead, outside the cabin also mounted to the bulkhead or on top of a tunnel adapter that can connect the pressurized Spacehab module with the Orbiter cabin. A docking module can also serve as an EVA airlock.

The airlock contains two spacesuits, expendables for two six-hour payload EVAs and one contingency or emergency EVA, and mobility aids such as handrails to enable the crew to perform a variety of tasks. The airlock allows two crewmen room for changing spacesuits.

Midfuselage

In addition to forming the payload bay of the Orbiter, the midfuselage supports the payload bay doors, hinges and tiedown fittings, the forward wing glove and various Orbiter system components.

Each payload bay door supports four radiator panels. When the doors are opened, the tilting radiators are unlatched and moved to the proper position. This allows heat radiation from both sides of the panels, whereas the four aft radiator panels radiate from the upper side only.

Some payloads may not be attached directly to the Orbiter but to payload carriers that are attached to the Orbiter. The inertial upper stage, pressurized modules or any specialized cradle for holding a payload are typical carriers.

The Remote Manipulator System, or RMS, is a 15.2-meter (50-foot) long articulating arm remotely controlled from the flight deck of the Orbiter. The elbow and wrist movements permit payloads to be grappled for deployment out of the payload bay or retrieved and secured for return to Earth.

A television camera and lights near the outer end of the arm permit the operator to see on television monitors what his hands are doing. In addition, three floodlights are located along each side of the payload bay.

The nominal maximum crew size is seven. The middeck can be reconfigured by adding three rescue seats in place of the modular stowage and sleeping provisions. The seating capacity will then accommodate the rescue flight crew of three and a maximum rescued crew of seven.

Aft Fuselage

The aft fuselage consists of the left and right orbital maneuvering systems, Space Shuttle main engines, body flap, vertical tail and Orbiter/external tank rear attachments.

The forward bulkhead closes off the aft fuselage from the midfuselage. The upper portion of the bulkhead attaches to the vertical tail. The internal thrust structure supports the three Space Shuttle main engines, low pressure turbopumps and propellant lines.

Main Engines

The three Space Shuttle Main Engines, in conjunction with the Solid Rocket Boosters, provide the thrust to lift the Orbiter off the ground for the initial ascent. The main engines continue to operate for 8.5 minutes after launch, the duration of the Shuttle’s powered flight.

After the solid rockets are jettisoned, the main engines provide thrust which accelerates the Shuttle from 4,828 kilometers per hour (3,000 mph) to over 27,358 kilometers per hour (17,000 mph) in just six minutes to reach orbit. They create a combined maximum thrust of more than 1.2 million pounds.

As the Shuttle accelerates, the main engines burn a half-million gallons of liquid propellant provided by the large, orange external fuel tank. The main engines burn liquid hydrogen—the second coldest liquid on Earth at minus 423 degrees Fahrenheit (minus 252.8 degrees Celsius)—and liquid oxygen.

The engines’ exhaust is primarily water vapor as the hydrogen and oxygen combine. As they push the Shuttle toward orbit, the engines consume liquid fuel at a rate that would drain an average family swimming pool in under 25 seconds generating over 37 million horsepower. Their turbines spin almost 13 times as fast as an automobile engine spins when it is running at highway speed.

The main engines develop thrust by using high-energy propellants in a staged combustion cycle. The propellants are partially combusted in dual preburners to produce high-pressure hot gas to drive the turbopumps.

Combustion is completed in the main combustion chamber. Temperatures in the main engine combustion chamber can reach as high as 6,000 degrees Fahrenheit (3,315.6 degrees Celsius).

Each Space Shuttle Main Engine operates at a liquid oxygen/liquid hydrogen mixture ratio of 6 to 1 to produce a sea level thrust of 179,097 kilograms (375,000 pounds) and a vacuum thrust of 213,188 (470,000 pounds).

The engines can be throttled over a thrust range of 65 percent to 109 percent, which provides for a high thrust level during liftoff and the initial ascent phase but allows thrust to be reduced to limit acceleration to 3 g’s during the final ascent phase. The engines are gimbaled to provide pitch, yaw and roll control during the ascent.

Solid Rocket Boosters

SRB Stats

Thrust at lift-off

2,650,000 pounds

Propellant Properties

16% Atomized aluminum powder (fuel)

69.8% Ammonium perchlorate (oxidizer)

.2% Iron oxide powder (catalyst )

12% Polybutadiene acrylic acid acrylonite (binder)

2% Epoxy curing agent

Weight

Empty: 193,000 pounds

Propellant: 1,107,000 pounds

Gross: 1,300,000 pounds

The Solid Rocket Boosters (SRBs) operate in parallel with the main engines for the first two minutes of flight to provide the additional thrust needed for the Orbiter to escape the gravitational pull of the Earth. At an altitude of approximately 45 km (24 nautical miles), the boosters separate from the orbiter/external tank, descend on parachutes, and land in the Atlantic Ocean. They are recovered by ships, returned to land, and refurbished for reuse. The boosters also assist in guiding the entire vehicle during initial ascent. Thrust of both boosters is equal to 5,300,000 lbs.

In addition to the solid rocket motor, the booster contains the structural, thrust vector control, separation, recovery, and electrical and instrumentation subsystems.

The solid rocket motor is the largest solid propellant motor ever developed for space flight and the first built to be used on a manned craft. The huge motor is composed of a segmented motor case loaded with solid propellants, an ignition system, a movable nozzle and the necessary instrumentation and integration hardware.

Each solid rocket motor contains more than 450,000 kg (1,000,000 lb.) of propellant, which requires an extensive mixing and casting operation at a plant in Utah. The propellant is mixed in 600 gallon bowls located in three different mixer buildings. The propellant is then taken to special casting buildings and poured into the casting segments.

Cured propellant looks and feels like a hard rubber typewriter eraser. The combined polymer and its curing agent is a synthetic rubber. Flexibility of the propellant is controlled by the ratio of binder to curing agent and the solid ingredients, namely oxidizer and aluminum. The solid fuel is actually powdered aluminum — a form similar to the foil wraps in your kitchen — mixed with oxygen provided by a chemical called ammonium perchlorate.

External Tank

External Tank Stats

Weight

Empty: 78,100 pounds

Propellant: 1,585,379 pounds

Gross: 1,667,677 pounds

Propellant Weight *

Liquid oxygen

1,359,142 pounds

Liquid hydrogen:

226,237 pounds

Gross

1,585,379 pounds

Propellant Volume *

Liquid oxygen tank

143,060 gallons

Liquid hydrogen tank

383,066 gallons

Gross

526,126 gallons

* Liquid oxygen is 16 times heavier than liquid hydrogen.

The External Tank, or ET, is the “gas tank” for the Orbiter; it contains the propellants used by the Space Shuttle Main Engines.

The tank is also the “backbone” of the Shuttle during the launch, providing structural support for attachment with the solid rocket boosters and orbiter.

The tank is the only component of the Space Shuttle that is not reused. Approximately 8.5 minutes into the flight, with its propellant used, the tank is jettisoned.

At liftoff, the External Tank absorbs the total (7.8 million pounds) thrust loads of the three main engines and the two solid rocket motors.

When the Solid Rocket Boosters separate at an altitude of approximately 45 kilometers (28 miles), the orbiter, with the main engines still burning, carries the external tank piggyback to near orbital velocity, approximately 113 kilometers (70 miles) above the Earth. The now nearly empty tank separates and falls in a preplanned trajectory with the majority of it disintegrating in the atmosphere and the rest falling into the ocean.

The three main components of the External Tank are an oxygen tank, located in the forward position, an aft-positioned hydrogen tank, and a collar-like intertank, which connects the two propellant tanks, houses instrumentation and processing equipment, and provides the attachment structure for the forward end of the solid rocket boosters.

The hydrogen tank is 2.5 times larger than the oxygen tank but weighs only one-third as much when filled to capacity. The reason for the difference in weight is that liquid oxygen is 16 times heavier than liquid hydrogen.

The skin of the External Tank is covered with a thermal protection system that is a 2.5-centimeter (1-inch) thick coating of spray-on polyisocyanurate foam. The purpose of the thermal protection system is to maintain the propellants at an acceptable temperature, to protect the skin surface from aerodynamic heat and to minimize ice formation.

The External Tank includes a propellant feed system to duct the propellants to the Orbiter engines, a pressurization and vent system to regulate the tank pressure, an environmental conditioning system to regulate the temperature and render the atmosphere in the intertank area inert, and an electrical system to distribute power and instrumentation signals and provide lightning protection.

The tank’s propellants are fed to the Orbiter through a 43-centimeter (17-inch) diameter connection that branches inside the orbiter to feed each main engine.

Orbiter Discovery (OV-103)

Discovery’s Final Launch

Discovery (OV-103) was NASA’s third space shuttle orbiter to join the fleet, arriving for the first time at the Kennedy Space Center in Florida in November 1983.

After checkout and processing, it was launched on Aug. 30, 1984, for its first mission, 41-D, to deploy three communications satellites.

Since that inaugural flight, Discovery has completed more than 30 successful missions, surpassing the number of flights made by any other orbiter in NASA’s fleet. Just like all of the orbiters, it has undergone some major modifications over the years. The most recent began in 2002 and was the first carried out at Kennedy. It provided 99 upgrades and 88 special tests, including new changes to make it safer for flight.

Discovery has the distinction of being chosen as the Return to Flight orbiter twice. The first was for STS-26 in 1988, and the second when it carried the STS-114 crew on NASA’s Return to Flight mission to the International Space Station in July 2005.

The choice of the name “Discovery” carried on a tradition drawn from some historic, Earth-bound exploring ships of the past. One of these sailing forerunners was the vessel used in the early 1600s by Henry Hudson to explore Hudson Bay and search for a northwest passage from the Atlantic to the Pacific.

Another such ship was used by British explorer James Cook in the 1770s during his voyages in the South Pacific, leading to the discovery of the Hawaiian Islands. In addition, two British Royal Geographical Society ships have carried the name “Discovery” as they sailed on expeditions to the North Pole and the Antarctic.

Destined for exploring the heavens instead of the seas, it was only fitting that NASA’s Discovery carried the Hubble Space Telescope into space during mission STS-31 in April 1990, and provided both the second and third Hubble servicing missions (STS-82 in February 1997 and STS-103 in December 1999).

During its many successful trips to space, Discovery has carried satellites aloft, ferried modules and crew to the International Space Station, and provided the setting for countless scientific experiments.

Construction Milestones

January 29, 1979 Contract Award

August 27, 1979 Start long lead fabrication of Crew Module

June 20, 1980 Start fabrication lower fuselage

November 10, 1980 Start structural assembly of aft-fuselage

December 8, 1980 Start initial system installation aft fuselage

March 2, 1981 Start fabrication/assembly of payload bay doors

October 26, 1981 Start initial system installation, crew module, Downey

January 4, 1982 Start initial system installation upper forward fuselage

March 16, 1982 Midfuselage on dock, Palmdale

March 30, 1982 Elevons on dock, Palmdale

April 30, 1982 Wings arrive at Palmdale from Grumman

April 30, 1982 Lower forward fuselage on dock, Palmdale

July 16, 1982 Upper forward fuselage on dock, Palmdale

August 5, 1982 Vertical stabilizer on dock, Palmdale

September 3, 1982 Start of Final Assembly

October 15, 1982 Body flap on dock, Palmdale

January 11, 1983 Aft fuselage on dock, Palmdale

February 25, 1983 Complete final assembly and closeout installation, Palmdale

February 28, 1983 Start initial subsystems test, power-on, Palmdale

May 13, 1983 Complete initial subsystems testing

July 26, 1983 Complete subsystems testing

August 12, 1983 Completed Final Acceptance

October 16, 1983 Rollout from Palmdale

November 5, 1983 Overland transport from Palmdale to Edwards

November 9, 1983 Delivery to Kennedy Space Center

June 2, 1984 Flight Readiness Firing

August 30, 1984 First Flight (41-D)

Upgrades and Features

Discovery benefited from lessons learned in the construction and testing of Enterprise, Columbia and Challenger. At rollout, its weight was some 6,870 pounds less than Columbia.

Beginning in the fall of 1995, the orbiter underwent a nine-month Orbiter Maintenance Down Period (OMDP) in Palmdale California. The vehicle was outfitted with a 5th set of cryogenic tanks and an external airlock to support missions to the International Space Station. It returned to the Kennedy Space Center, riding piggy-back on a modified Boeing 747, in June 1996.

Following STS-105, Discovery became the first of the orbiter fleet to undergo Orbiter Major Modification (OMM) period at the Kennedy Space Center. Work began in September 2002, and along with the scheduled upgrades, additional safety modifications were added as part of the preparations for Return to Flight.

Orbiter Endeavour (OV-105)

Endeavour’s Final Launch

Authorized by Congress in August 1987 as a replacement for the Space Shuttle orbiter Challenger, Endeavour (OV-105) arrived at Kennedy Space Center’s Shuttle Landing Facility on May 7, 1991, piggy-backed on top of NASA’s new Space Shuttle Carrier Aircraft.

For the first time, an orbiter was named through a national competition involving students in elementary and secondary schools. They were asked to select a name based upon an exploratory or research sea vessel. In May 1989, President George Bush announced the winning name.

Endeavour was named after a ship chartered to traverse the South Pacific in 1768 and captained by 18th century British explorer James Cook, an experienced seaman, navigator and amateur astronomer. He commanded a crew of 93 men, including 11 scientists and artists.

Cook’s main objective, tasked by the British Admiralty and the Royal Society, was to observe the Transit of Venus at Tahiti. This reading enabled astronomers to find the distance of the Sun from the Earth, which then could be used as a unit of measurement in calculating the parameters of the universe.

Cook’s achievements on Endeavour were numerous, including the accurate charting of New Zealand and Australia and successfully navigating the Great Barrier Reef. Thousands of new plant specimens and animal species were observed and illustrated on this maiden voyage. Cook also established the usefulness of including scientists on voyages of exploration.

Space Shuttle Endeavour embodies similar experiences. Its first launch, the STS-49 mission, began with a flawless liftoff on May 7, 1992, beginning a journey filled with excitement, anticipation and many firsts.

One of Endeavour’s primary assignments was to capture INTELSAT VI, an orbiting, but not functioning, communications satellite, and replace its rocket motor. Unfortunately, the Space Shuttle wasn’t designed to retrieve the satellite, which created many repair challenges.

The project sparked public interest in the mission and NASA received a deluge of suggestions on possible ways for the crew to grab onto the satellite. It took three attempts to capture the satellite for repairs to be made. An unprecedented three-person spacewalk took place after the procedure was evaluated by the astronauts and ground team.

Between rescue attempts, the STS-49 crew was busy with a variety of activities. They conducted medical tests assessing the human body’s performance in microgravity, and recorded footage for an educational video comparing Cook’s first voyage on Endeavour with the Space Shuttle orbiter’s maiden voyage.

Once the new motor was attached, it propelled the satellite into the correct orbit, providing a relay link for the equivalent of 120,000 two-way simultaneous telephone calls and three television channels.

This was the first time four spacewalks were conducted on a Space Shuttle mission and one of them was the longest in space history, lasting more than eight hours.

The crew also took part in the Commercial Protein Crystal Growth experiment. The research tested the production of protein crystals grown in microgravity.

Because of Endeavour’s excellent performance, NASA decided to extend the flight two days to complete more mission objectives and allow the crew enough time to prepare for landing.

OV-105 became the first Space Shuttle orbiter to use a drag chute during a landing — only one of many technical improvements made to Endeavour.

Just as James Cook set the standard with his seafaring Endeavour voyage, the Space Shuttle Endeavour missions have continued to uphold and surpass the standards set by its namesake, more than 200 years later.

Construction Milestones

February 15, 1982 Start structural assembly of Crew Module

July 31, 1987 Contract Award

September 28, 1987 Start structural assembly of aft-fuselage

December 22, 1987 Wings arrive at Palmdale, Calif. from Grumman

August 1, 1987 Start of Final Assembly

July 6, 1990 Completed final assembly

April 25, 1991 Rollout from Palmdale

May 7, 1991 Delivery to Kennedy Space Center

April 6, 1992 Flight Readiness Firing

May 7, 1992 First Flight (STS-49)

Upgrades and Features

Spare parts from the construction of Discovery (OV-103) and Atlantis (OV-104), manufactured to facilitate the repair of an orbiter if needed, were eventually used to build OV-105.

Endeavour also featured new hardware, designed to improve and expand orbiter capabilities. Most of this equipment was later incorporated into the other three orbiters during out-of-service major inspection and modification programs.

Endeavour’s upgrades include:

- A 40-foot-diameter drag chute that reduces the orbiter’s rollout distance by 1,000 to 2,000 feet.

- An updated avionics system that include advanced general purpose computers, improved inertial measurement units and tactical air navigation systems, enhanced master events controllers and multiplexer-demultiplexers, a solid-state star tracker.

- Improved nose wheel steering mechanisms.

- An improved version of the Auxiliary Power Units that provide power to operate the Space Shuttle’s hydraulic systems.

- Installation of an external airlock, making Endeavour capable of docking with the International Space Station.

- Originally equipped as the first extended duration orbiter, later removed during OMDP to save weight for ISS missions.

- Installation of a ground cooling hookup to allow payload bay to cool the mini-pressurized logistics module (MPLM).

- General weight-reduction program to maximize the payload capability to the ISS.

- Doublers added to several wing spars to allow heavier payloads and two wing glove truss tubes were replaced with units having increased wall thickness.

- Approximately 100 modifications made to Endeavour during its first Orbiter Major Modification period (OMDP).

Space Shuttle Endeavour’s OMDP began in December 2003. Engineers and technicians spent 900,000 hours performing 124 modifications to the vehicle. These included recommended return to flight safety modifications, bonding more than 1,000 thermal protection system tiles and inspecting more than 150 miles of wiring. Eighty five of the modifications are complete and 39 are still underway.

Two of the more extensive modifications included the addition of the multi-functional electronic display system (glass cockpit), and the three-string global positioning system.

The glass cockpit is a new, full-color, flat-panel display system that improves interaction between the crew and orbiter. It provides easy-to-read graphics portraying key flight indicators like attitude display and mach speed. Endeavour was the last vehicle in the fleet to receive this system.

The three-string global positioning system will improve the shuttle’s landing capability. It will allow Endeavour to make a landing at any runway long enough to handle the shuttle. The previous system only allowed for landings at military bases. Shuttle major modification periods are scheduled at regular intervals to enhance safety and performance, infuse new technology and allow thorough inspections of the airframe and wiring. This was the second of modification period performed entirely at Kennedy. Endeavour’s previous modification was completed in March 1997.

Endeavour has undergone extensive modifications, including the addition of all of the return-to-flight safety upgrades added to both Discovery and Atlantis.

Endeavour’s flight on mission STS-118 was the first launch for the orbiter in more than four years.

Orbiter Atlantis (OV-104)

Atlantis’s Final Launch

NASA’s fourth space-rated space shuttle, OV-104 “Atlantis,” was named after the two-masted boat that served as the primary research vessel for the Woods Hole Oceanographic Institute in Massachusetts from 1930 to 1966. The boat had a 17-member crew and accommodated up to five scientists who worked in two onboard laboratories, examining water samples and marine life. The crew also used the first electronic sounding devices to map the ocean floor.

Construction of the orbiter Atlantis began on March 3, 1980. Thanks to lessons learned in the construction and testing of orbiters Enterprise, Columbia and Challenger, Atlantis was completed in about half the time in man-hours spent on Columbia. This is largely attributed to the use of large thermal protection blankets on the orbiter’s upper body, rather than individual tiles requiring more attention.

Weighing in at 151,315 pounds when it rolled out of the assembly plant in Palmdale, Calif., Atlantis was nearly 3.5 tons lighter than Columbia. The new orbiter arrived at NASA’s Kennedy Space Center in Florida on April 9, 1985, and over the next seven months was prepared for her maiden voyage.

Like her seafaring predecessor, orbiter Atlantis \carried on the spirit of exploration with several important missions of her own. On Oct. 3, 1985, Atlantis launched on her first space flight, STS 51-J, with a classified payload for the U.S. Department of Defense. The vehicle went on to carry four more DOD payloads on later missions.

Atlantis also served as the on-orbit launch site for many noteworthy spacecraft, including planetary probes Magellan and Galileo, as well as the Compton Gamma Ray Observatory. An impressive array of onboard science experiments took place during most missions to further enhance space research in low Earth orbit.

Starting with STS-71, Atlantis pioneered the Shuttle-Mir missions, flying the first seven missions to dock with the Russian space station. When linked, Atlantis and Mir together formed the largest spacecraft in orbit at the time. The missions to Mir included the first on-orbit U.S. crew exchanges, now a common occurrence on the International Space Station. On STS-79, the fourth docking mission, Atlantis ferried astronaut Shannon Lucid back to Earth after her record-setting 188 days in orbit aboard Mir.

In recent years, Atlantis has delivered several vital components to the International Space Station, including the U.S. laboratory module, Destiny, as well as the Joint Airlock Quest and multiple sections of the Integrated Truss structure that makes up the station’s backbone.

Construction Milestones – OV-104

Jan. 29, 1979 Contract Award

March 30, 1980 Start structural assembly of crew module

Nov. 23, 1981 Start structural assembly of aft-fuselage

June 13, 1983 Wings arrive at Palmdale from Grumman

Dec. 2, 1983 Start of Final Assembly

April 10, 1984 Completed final assembly

March 6, 1985 Rollout from Palmdale

April 3, 1985 Overland transport from Palmdale to Edwards

April 13, 1985 Delivery to Kennedy Space Center

Sept. 12, 1985 Flight Readiness Firing

Oct. 3, 1985 First Flight (STS 51-J)

Upgrades and Features

By early 2005, Atlantis had undergone two overhauls known as Orbiter Maintenance Down Periods. Some of the most significant upgrades and new features included:

- Installation of the drag chute

- New plumbing lines and electrical connections configuring the orbiter for extended duration missions

- New insulation for the main landing gear doors

- Improved nosewheel steering

- Preparations for the Mir Orbiter Docking System unit later installed at Kennedy

- Installation of the International Space Station airlock and Orbiter Docking System

- Installation of the Multifunction Electronic Display System, or “glass cockpit”

Orbiter Challenger (OV-099)

First called STA-099, Challenger was built to serve as a test vehicle for the Space Shuttle program. But despite its Earth-bound beginnings, STA-099 was destined for space.

In the late 1970s, NASA strived for a lighter weight orbiter, but a test vehicle was needed to ensure the lighter airframe could handle the stress of space flight. Computer software at the time wasn’t yet advanced enough to accurately predict how STA-099’s new, optimized design would respond to intense heat and stress. The best solution was to submit the vehicle to a year of intensive vibration and thermal testing.

In early 1979, NASA awarded Space Shuttle orbiter manufacturer Rockwell a contract to convert STA-099 to a space-rated orbiter, OV-099. The vehicle’s conversion began late that year. Although the job was easier than it would have been to convert NASA’s first orbiter, Enterprise, it was a major process that involved the disassembly and replacement of many parts and components.

The second orbiter to join NASA’s Space Shuttle fleet, OV-099 arrived at NASA’s Kennedy Space Center in Florida in July 1982, bearing the name “Challenger.”

Space Shuttle orbiter Challenger was named after the British Naval research vessel HMS Challenger that sailed the Atlantic and Pacific oceans during the 1870s. The Apollo 17 lunar module also carried the name of Challenger. Like its historic predecessors, Challenger and her crews made significant scientific contributions in the spirit of exploration.

Challenger launched on her maiden voyage, STS-6, on April 4, 1983. That mission saw the first spacewalk of the Space Shuttle program, as well as the deployment of the first satellite in the Tracking and Data Relay System constellation. The orbiter launched the first American woman, Sally Ride, into space on mission STS-7 and was the first to carry two U.S. female astronauts on mission STS 41-G.

The first orbiter to launch and land at night on mission STS-8, Challenger also made the first Space Shuttle landing at Kennedy Space Center, concluding mission STS 41-B. Spacelabs 2 and 3 flew aboard the ship on missions STS 51-F and STS 51-B, as did the first German-dedicated Spacelab on STS 61-A. A host of scientific experiments and satellite deployments were performed during Challenger’s missions.

Challenger’s service to America’s space program ended in tragedy on Jan. 28, 1986. Just 73 seconds into mission STS 51-L, a booster failure caused an explosion that resulted in the loss of seven astronauts, as well as the vehicle.

The loss of Challenger does not overshadow her legacy in NASA’s storied history. The discoveries made on her many successful missions continue to better mankind in space flight and in life on Earth.

Construction Milestones – STA-099

July 26, 1972 Contract Award

Nov. 21, 1975 Start structural assembly of crew module

June 14, 1976 Start structural assembly of aft-fuselage

March 16, 1977 Wings arrive at Palmdale from Grumman

Sept. 30, 1977 Start of Final Assembly

Feb. 10, 1978 Completed final assembly

Feb. 14, 1978 Rollout from Palmdale

Construction Milestones – OV-099

Jan. 1, 1979 Contract Award

Jan. 28, 1979 Start structural assembly of crew module

June 14, 1976 Start structural assembly of aft-fuselage

March 16, 1977 Wings arrive at Palmdale from Grumman

Nov. 3, 1980 Start of Final Assembly

Oct. 21, 1981 Completed final assembly

June 30, 1982 Rollout from Palmdale

July 1, 1982 Overland transport from Palmdale to Edwards

July 5, 1982 Delivery to Kennedy Space Center

Dec. 19, 1982 Flight Readiness Firing

April 4, 1983 First Flight (STS-6)

Orbiter Columbia (OV-102)

On April 12, 1981, a bright white Columbia roared into a deep blue sky as the nation’s first reusable Space Shuttle. Named after the first American ocean vessel to circle the globe and the command module for the Apollo 11 Moon landing, Columbia continued this heritage of intrepid exploration. The heaviest of NASA’s orbiters, Columbia weighed too much and lacked the necessary equipment to assist with assembly of the International Space Station. Despite its limitations, the orbiter’s legacy is one of groundbreaking scientific research and notable “firsts” in space flight.

Space Shuttle mission STS-9, launched in late November 1983, was the maiden flight for Spacelab. Designed to be a space-based science lab, Spacelab was installed inside the orbiter’s cargo bay. Spacelab featured an enclosed crew work module connected to an outside payload pallet, which could be mounted with various instruments and experiments. From inside the lab, astronauts worked with the experiments on the pallet and within the crew module itself. The lab would go on to fly aboard the rest of the fleet, playing host throughout its accomplished lifetime to unprecedented research in astronomy, biology and other sciences. Spacelab ultimately finished where its career began; its 16th and final mission was hoisted into space aboard Columbia in 1998.

In addition to Columbia’s STS-1 flight and Spacelab, the orbiter was also the stage for many other remarkable firsts. Germany’s Dr. Ulf Merbold became the first European Space Agency astronaut when he flew aboard 1983’s STS-9. The Japanese Space Agency and STS-65’s Chiaki Mukai entered history as the first Japanese woman to fly in space in 1994. In a display of national pride, the crew of STS-73 even “threw” the ceremonial first pitch for game five of the 1995 baseball World Series, marking the first time the pitcher was not only outside of the stadium, but out of this world.

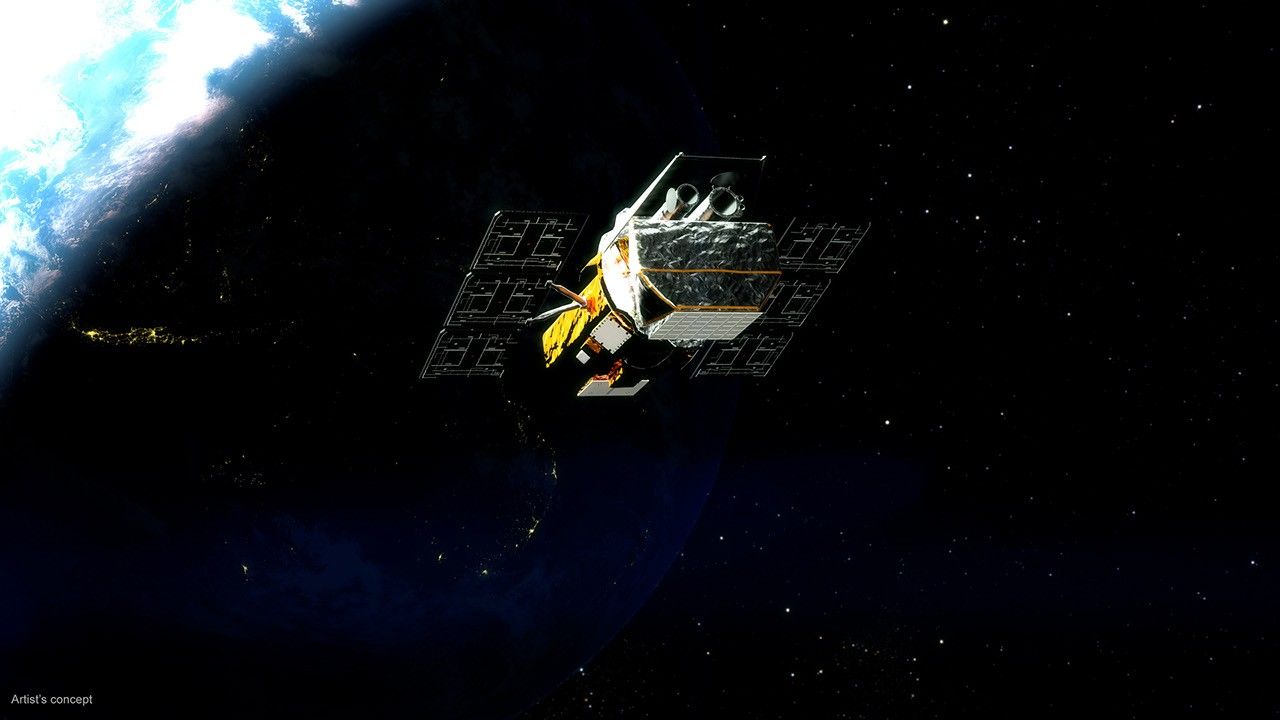

Perhaps Columbia’s crowning achievement was the deployment of the gleaming Chandra X-ray Observatory in July 1999. Carried into space inside the orbiter’s payload bay, the slender and elegant Chandra telescope was released on July 23. Still in flight today, the X-ray telescope specializes in viewing deep space objects and finding the answers to astronomy’s most fundamental questions.

Columbia and its crew were tragically lost during STS-107 in 2003. As the Space Shuttle lifted off from Kennedy Space Center in Florida on January 16, a small portion of foam broke away from the orange external fuel tank and struck the orbiter’s left wing. The resulting damage created a hole in the wing’s leading edge, which caused the vehicle to break apart during reentry to Earth’s atmosphere on February 1.

Construction Milestones

July 26, 1972 Contract Award

March 25, 1975 Start long lead fabrication aft fuselage

November 17, 1975 Start long-lead fabrication of crew module

June 28, 1976 Start assembly of crew module

September 13, 1976 Start structural assembly of aft-fuselage

December 13, 1976 Start assembly upper forward fuselage

January 3, 1977 Start assembly vertical stabilizer

August 26, 1977 Wings arrive at Palmdale from Grumman

October 28, 1977 Lower forward fuselage on dock, Palmdale

November 7, 1977 Start of Final Assembly

February 24, 1978 Body flap on dock, Palmdale

April 28, 1978 Forward payload bay doors on dock, Palmdale

May 26,1978 Upper forward fuselage mate

July 7, 1978 Complete mate forward and aft payload bay doors

September 11, 1978 Complete forward RCS

February 3, 1979 Complete combined systems test, Palmdale

February 16, 1979 Airlock on dock, Palmdale

March 5, 1979 Complete postcheckout

March 8, 1979 Closeout inspection, Final Acceptance Palmdale

March 8, 1979 Rollout from Palmdale to Dryden (38 miles)

March 12, 1979 Overland transport from Palmdale to Edwards

March 20, 1979 SCA Ferry Flight from DFRF to Bigs AFB, Texas

March 22, 1979 SCA Ferry flight from Bigs AFB to Kelly AFB, Texas

March 24, 1979 SCA Ferry flight from Kelly AFB to Eglin AFB, Florida

March 24, 1979 SCA Ferry flight from Eglin, AFB to KSC

November 3, 1979 Auxiliary Power Unit hot fire tests, OPF KSC

December 16, 1979 Orbiter integrated test start, KSC

January 14, 1980 Orbiter integrated test complete, KSC

February 20, 1981 Flight Readiness Firing

April 12, 1981 First Flight (STS-1)

Upgrades and Features

Columbia is commonly referred to as OV-102, for Orbiter Vehicle-102. The orbiter weighed 178,000 pounds with its main engines installed.

Columbia was the first orbiter to undergo the scheduled inspection and retrofit program. In 1991, Columbia returned to its birthplace at Rockwell International’s Palmdale, Calif., assembly plant. The spacecraft underwent approximately 50 upgrades there, including the addition of carbon brakes and a drag chute, improved nose wheel steering, removal of instrumentation used during the test phase of the orbiter, and an enhancement of its Thermal Protection System. The orbiter returned to Florida in February 1992 to begin processing for mission STS-50, launching in June of that year.

In 1994, Columbia was transported back to Palmdale for its first major tear-down and overhaul, known as the Orbiter Maintenance Down Period (OMDP). This overhaul typically lasts one year or longer and leaves the vehicle in “like-new” condition.

Its second OMDP came in 1999, when workers performed more than 100 modifications on the vehicle. The orbiter’s most impressive upgrade likely was the installation of a state-of-the-art, Multi-functional Electronic Display System (MEDS), or “glass cockpit.” The MEDS replaced traditional instrument dials and gauges with small, computerized video screens. The new system improved crew interaction with the orbiter during flight and reduced maintenance costs by eliminating the outdated and tricky electromechanical displays.

Orbiter Enterprise (OV-101)

Designated OV-101, the vehicle was rolled out of Rockwell’s Air Force Plant 42, Site 1 Palmdale California assembly facility on Sept. 17, 1976. On Jan. 31, 1977, it was transported 36 miles overland from Rockwell’s assembly facility to NASA’s Dryden Flight Research Facility at Edwards Air Force Base for the approach and landing test program.

The nine-month-long Approach and Landing Test, or ALT, program was conducted from February through November 1977 at the Dryden Flight Research Facility and demonstrated that the orbiter could fly in the atmosphere and land like an airplane, except without power-gliding flight.

Empty Weight was 151,315 lbs at rollout and 171,000 lbs with main engines installed.

Two NASA astronaut crews-Fred Haise and Gordon Fullerton and Joe Engle and Dick Truly-took turns flying the 150,000-pound spacecraft to free-flight landings.

The ALT program involved ground tests and flight tests. The ground tests included taxi tests of the 747 shuttle carrier aircraft with the Enterprise mated atop the Shuttle Carrier Aircraft, or SCA, to determine structural loads and responses and assess the mated capability in ground handling and control characteristics up to flight takeoff speed. The taxi tests also validated 747 steering and braking with the orbiter attached. A ground test of orbiter systems followed the unmanned captive tests. All orbiter systems were activated as they would be in atmospheric flight. This was the final preparation for the manned captive flight phase.

Five captive flights of the Enterprise mounted atop the SCA with the Enterprise unmanned and Enterprise’s systems inert were conducted to assess the structural integrity and performance handling qualities of the mated craft.

Three manned captive flights that followed the five captive flights included an astronaut crew aboard the orbiter operating its flight control systems while the orbiter remained perched atop the SCA. These flights were designed to exercise and evaluate all systems in the flight environment in preparation for the orbiter release (free) flights. They included flutter tests of the mated craft at low and high speed, a separation trajectory test and a dress rehearsal for the first orbiter free flight.

In the five free flights the astronaut crew separated the spacecraft from the SCA and maneuvered to a landing at Edwards Air Force Base. In the first four such flights the landing was on a dry lake bed; in the fifth, the landing was on Edwards’ main concrete runway under conditions simulating a return from space. The last two free flights were made without the tail cone, which is the spacecraft’s configuration during an actual landing from Earth orbit. These flights verified the orbiter’s pilot-guided approach and landing capability; demonstrated the orbiter’s subsonic terminal area energy management autoland approach capability; and verified the orbiter’s subsonic airworthiness, integrated system operation and selected subsystems in preparation for the first manned orbital flight. The flights demonstrated the orbiter’s ability to approach and land safely with a minimum gross weight and using several center-of-gravity configurations.

For all of the captive flights and the first three free flights, the orbiter was outfitted with a tail cone covering its aft section to reduce aerodynamic drag and turbulence. The final two free flights were without the tail cone, and the three simulated space shuttle main engines and two orbital maneuvering system engines were exposed aerodynamically.

The final phase of the ALT program prepared the spacecraft for four ferry flights. Fluid systems were drained and purged, the tail cone was reinstalled, and elevon locks were installed. The forward attachment strut was replaced to lower the orbiter’s cant from 6 to 3 degrees. This reduces drag to the mated vehicles during the ferry flights.

After the ferry flight tests, OV-101 was returned to the NASA hangar at the Dryden Flight Research Facility and modified for vertical ground vibration tests at the Marshall Space Flight Center, Huntsville, Ala.

On March 13, 1978, the Enterprise was ferried atop the SCA to NASA’s Marshall Space Flight Center, where it was mated with the external tank and solid rocket boosters and subjected to a series of vertical ground vibration tests. These tested the mated configuration’s critical structural dynamic response modes, which were assessed against analytical math models used to design the various element interfaces.

These were completed in March 1979. On April 10, 1979, the Enterprise was ferried to the Kennedy Space Center and mated with the external tank and solid rocket boosters and transported via the mobile launcher platform to Launch Complex 39-A. At Launch Complex 39-A, the Enterprise served as a practice and launch complex fit-check verification tool representing the flight vehicles.

It was ferried back to NASA’s Dryden Flight Research Facility on Aug. 16, 1979, and then returned overland to Rockwell’s Palmdale final assembly facility on Oct. 30, 1979. Certain components were refurbished for use on flight vehicles being assembled at Palmdale. The Enterprise was then returned overland to the Dryden Flight Research Facility on Sept. 6, 1981.

From May of 1983 until Nov. 1985, Enterprise was ferried to the Paris, France, Air Show, as well as to Germany, Italy, England and Canada, to Vandenberg Air Force Base in California and to Mobile, Ala. From there it was taken by barge to New Orleans, La., for the United States 1984 World’s Fair. It was then ferried to Vandenberg Air Force Base and used as a practice and fit-check verification tool. Afterwards, the Enterprise was ferried from Vandenberg Air Force Base to NASA’s Dryden Flight Research Facility. Eventually, Enterprise was ferried from the Kennedy Space Center to Dulles Airport, Washington, D.C., and became the property of the Smithsonian Institution. The Enterprise was built as a test vehicle and is not equipped for space flight.

Following in the Enterprise’s creation, the orbiter Columbia was created and became the first Space Shuttle to fly into Earth orbit in 1981. Columbia was lost in its return flight in 2003. Four sister ships joined the fleet over the next 10 years: Challenger, arriving in 1982 but destroyed four years later; Discovery, 1983; Atlantis, 1985; and Endeavour, built as a replacement for Challenger, 1991.

Construction Milestones

July 26, 1972 Contract Award

June 4, 1974, Start structural assembly of Crew Module

August 26, 1974, Start structural assembly of aft-fuselage

May 23, 1975, Wings arrive at Palmdale from Grumman

August 24, 1975, Start of Final Assembly

March 12, 1975, Completed final assembly

September 17, 1976, Rollout from Palmdale

January 31, 1977, Overland transport from Palmdale to Edwards

April 10, 1979, Delivery to Kennedy Space Center