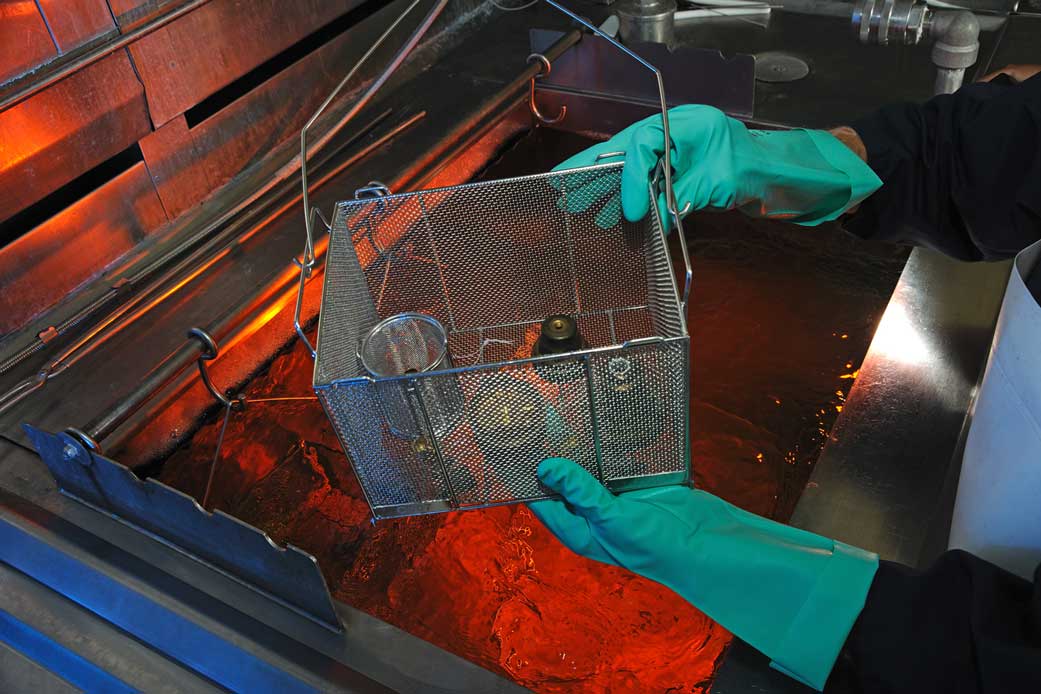

Components and materials not properly cleaned for use in oxygen service may be susceptible to ignition and burning. If contamination is not removed, they may hinder a components operation and increase ignition hazards. Our Oxygen team understands the effects of system and component cleanliness on oxygen hazards. We are able to assess your system and determine appropriate cleanliness levels through our oxygen compatibility assessment. We can also conduct testing to evaluate if current cleanliness levels are effective in controlling your oxygen hazards.

Our Precision Cleaning personnel have developed customized oxygen cleaning procedures to remove both organic and inorganic contaminants including hydrocarbons such as oils and greases, paper, solvents, fiber, dust, weld slag, rust, dirt, and sand from the surface of any equipment or system in oxygen service. The removal of these contaminates extends the life and performance of components and systems and maintains a safe environment.

1 min read