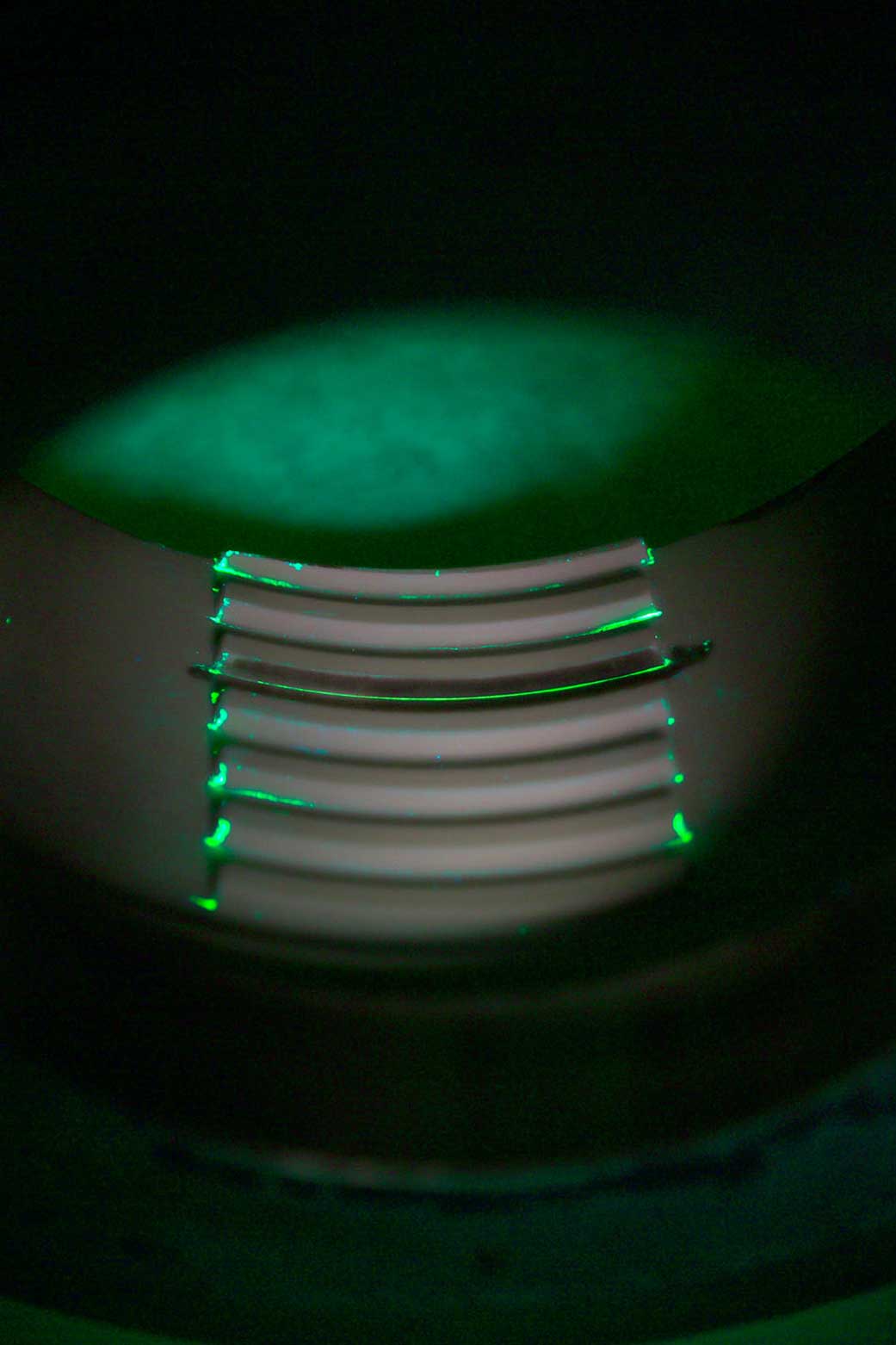

Penetrant inspection is a nondestructive method commonly used to reveal surface flaws on metals, glass, ceramic, rubber, and plastic materials on large and small surface areas.

A colored or fluorescent penetrant dye is applied to a clean surface and the excess penetrant is removed. A thin layer of developer is then applied to draw penetrant trapped in flaws back to the surface. The appropriate light source is applied to detect indications of any flaws which may be present. Colored penetrants require strong white light while fluorescent liquids require an ultraviolet light and darkened conditions.

1 min read