In This Week’s Star

- Marshall Leaders Provide Updates, Answer Questions During Hybrid Town Hall

- Dayna Ise Named Deputy Manager of Marshall’s Science and Technology Office

- Progress Continues Toward Artemis I Launch

- NASA, Northrop Grumman to Test Fire Future Artemis Booster Motor

- Decade of Excellence: NASA Named Best Place to Work 10th Year in a Row

- Dragon Docks to Space Station, Delivering Science Benefiting Humans

- Jacobs’ Steve Arnette is Next Mission Success Speaker

- Marshall Joins ‘Plastic Free July’ Challenge

Marshall Leaders Provide Updates, Answer Questions During Hybrid Town Hall

NASA’s Marshall Space Flight Center leaders, from left, Deputy Director Joseph Pelfrey, Director Jody Singer, and Associate Director Rae Ann Meyer, address team members during a hybrid town hall July 13. They discussed upcoming mission milestones, the latest on the Artemis I mission, and updates about the hybrid work environment. “Being at the wet dress rehearsal at Kennedy Space Center last month was such a thrilling experience, and you really get a sense that the launch of Artemis I is here,” Singer said. “I can’t wait to be back at the cape to watch the Space Launch System rocket fly for the first time and see years of hard work by so many people come to realization.” The leaders also answered questions submitted by the workforce. Topics included return to on-site work, COVID-19, and center culture. “We are all adjusting to this new hybrid way of working,” Meyer said. “Your feedback to your supervisors is important as we use it to learn what works best for the workplace and where improvements can be made.” Pelfrey touched on Marshall’s strategy regarding the center’s future role in space exploration. “We stand on the shoulders of our propulsion heritage,” he said. “And we look to a future where we’re not only providing innovation for NASA missions but also for commercial industry and joining them on their journey of exploration goals.” A recording of the town hall is available here. (NASA)

Dayna Ise Named Deputy Manager of Marshall’s Science and Technology Office

Dayna Ise has been named deputy manager of the Science and Technology Office at NASA’s Marshall Space Flight Center.

Ise will assist in leading the organization responsible for projects and programs in support of the Science Mission Directorate and Space Technology Mission Directorate. This includes the Planetary Missions Program Office, the Technology Demonstration Missions Program Office, deep space and planetary exploration, fundamental research in heliophysics, astrophysics, and Earth science, and technology development, including Centennial Challenges and Technology Transfer. The office also leads the pursuit of new partnership opportunities with other government agencies and private industry. Ise will help oversee an annual budget of more than $200 million and manage a diverse, highly technical workforce of approximately 300 civil service and contractor employees.

Since 2021, Ise has been the project manager for Space Nuclear Propulsion at Marshall, which included both the nuclear thermal and nuclear electric propulsion projects. She oversaw the award of three industry contracts for preliminary design of a nuclear thermal rocket engine reactor.

Ise was named division chief in the Systems Development, Integration, and Test Division in the Engineering’s Space Systems Department in 2019. In that position, she managed the Environmental Control and Life Support System group and the test group for International Space Station payloads and System Integration Lab testing.

She was named program executive for Technology Demonstration Missions at NASA Headquarters in the Space Technology Mission Directorate in 2018. Ise was named deputy launch vehicle manager for the Commercial Crew Program in 2011.

From 2008 to 2011, she was integrated product team lead for systems on Ares Upper Stage on the Constellation Program. Ise was named engine systems lead for RS-68 on Ares V in 2006. She started her NASA career in 2000 as an engine systems data analyst and modeler for space shuttle main engine. Her awards include a Silver Snoopy.

A native of Joliet, Illinois, Ise received a bachelor’s degree in mechanical engineering from the University of Alabama in Huntsville. She and her husband, Carl, live in Huntsville with their two sons, Sven and Charles.

Progress Continues Toward Artemis I Launch

Technicians continue to prepare the Space Launch System rocket and Orion spacecraft for Artemis I inside the Vehicle Assembly Building at NASA’s Kennedy Space Center.

During a media teleconference July 20, Jim Free, associate administrator, Exploration Systems Development Mission Directorate, said there are placeholders on the range for launch attempts on Aug. 29, Sept. 2, and Sept. 5. He explained the team is working toward those dates but that an actual launch date would not be set until about a week before launch.

During work to repair the source of a hydrogen leak, engineers identified a loose fitting on the inside wall of the rocket’s engine section, where the quick disconnect for the liquid hydrogen umbilical attaches. The component, called a “collet,” is a fist-sized ring that guides the quick disconnect during assembly operations. Teams repaired the collet by entering the engine section in parallel with other planned work for launch preparations. Technicians have replaced the seals on the quick disconnect of the tail service mast umbilical and are in the process of reattaching the umbilical plate and testing the new quick disconnects.

Technicians continue work associated with battery activations, and planned to turn on the core stage batteries before they are installed on the rocket. Next up, teams will start the flight termination systems operations, which include removing the core stage and booster safe and arm devices for calibration and removing and replacing the command receiver decoders with the flight units. The safe and arm devices are a manual mechanism that put the flight termination system in either a “safe” or “arm” configuration while the command receiver decoders receive and decode the command on the rocket if the system is activated.

Meanwhile on the Orion spacecraft, teams installed a technology demonstration that will test digital assistance and video collaboration in deep space. Engineers are also conducting powered testing on the crew module and European service module heaters and sensors.

NASA, Northrop Grumman to Test Fire Future Artemis Booster Motor

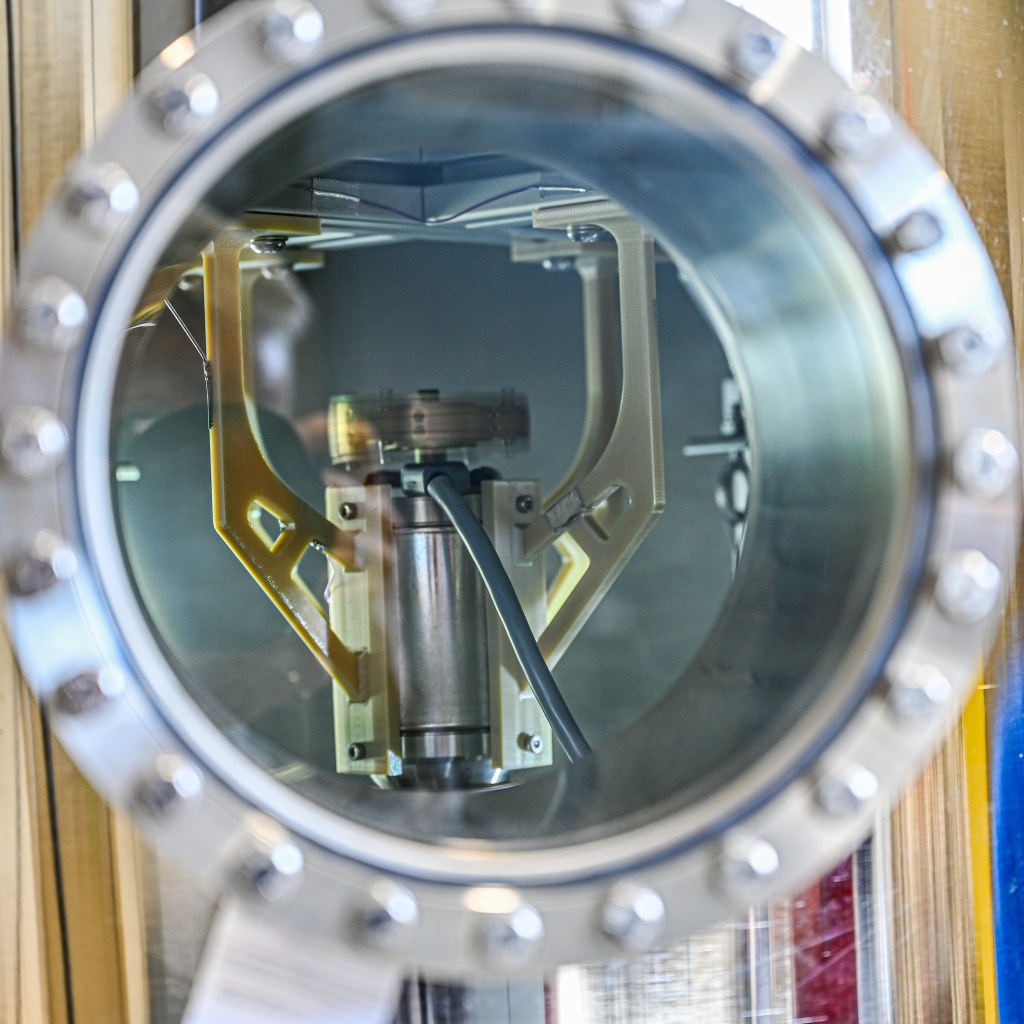

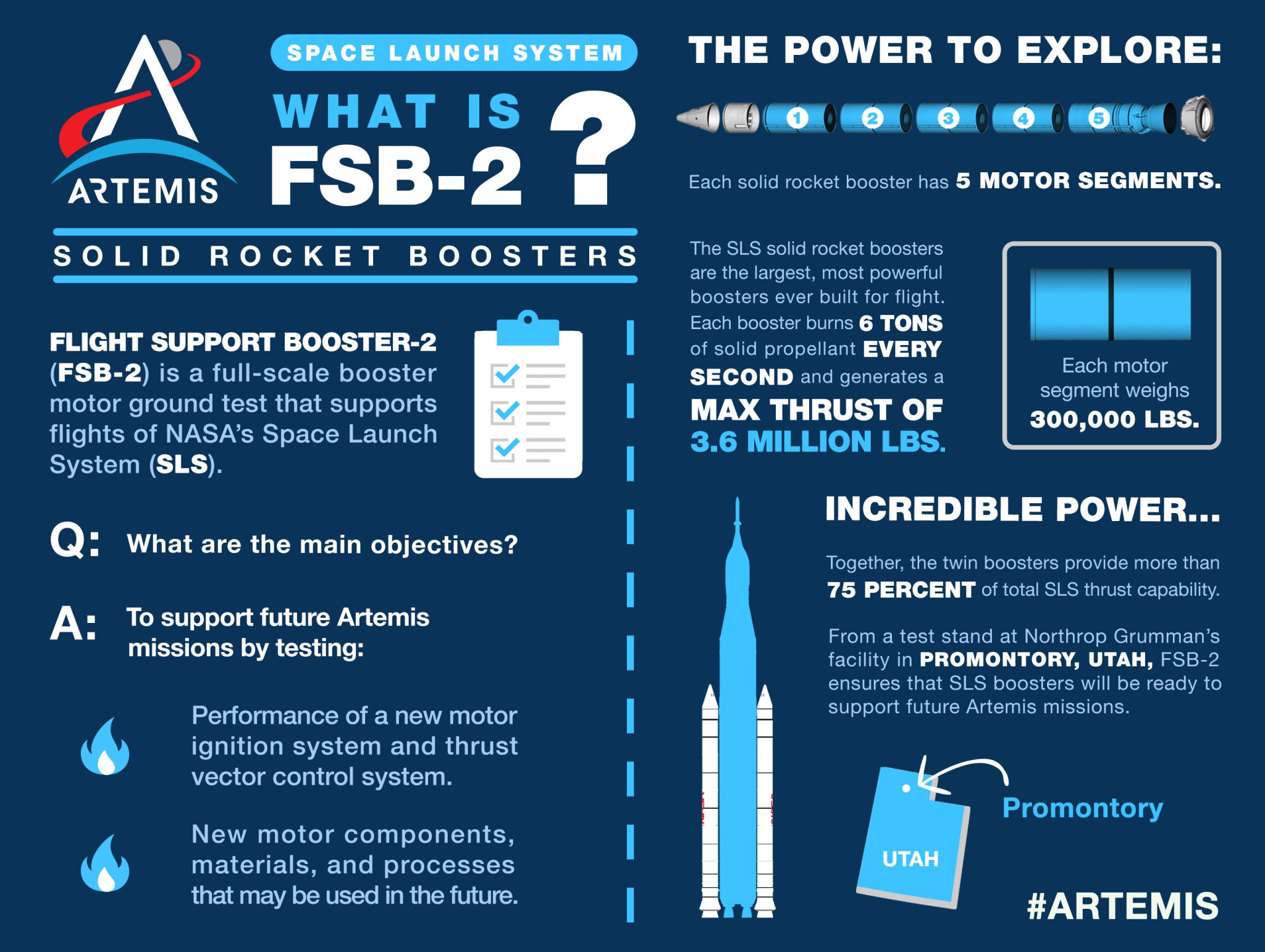

NASA and Northrop Grumman will perform a full-scale static test of a Space Launch System (SLS) solid rocket booster motor at Northrop Grumman’s Promontory, Utah, test facility July 21. Engineers will fire the booster during the demonstration, called the Flight Support Booster 2 test, to evaluate materials and processes to improve boosters for future Artemis missions.

“The current SLS boosters for the first eight Artemis missions are using a robust mix of new avionics and substantial heritage hardware from the Space Shuttle Program,” said Bruce Tiller, SLS Booster Program manager. “This particular ground test will demonstrate some new materials, a completely new steering system, and a new way to ignite the motor. Data from this test will improve our booster design for future missions that take us farther into deep space than ever before.”

For the test, one booster is affixed in a horizontal test stand and fired for approximately two minutes, the same amount of time and at the same power level as it would be fired during launch. On launch day, a pair of solid rocket boosters in a vertical position attached to the core stage of the SLS rocket supply more than 75% of the total thrust for the first two minutes of flight. Northrop Grumman is the lead contractor for the SLS solid rocket boosters.

NASA and Northrop Grumman experts will discuss the Flight Support Booster 2 test during a Facebook Live on the Space Launch System rocket’s Facebook page, as well as on NASA’s Marshall Space Flight Center YouTube channel, beginning at 1:55 p.m. During the test, anyone can submit questions on Twitter, Facebook, and YouTube using the hashtag #AskNASA. Julia Khodabandeh, motor team lead for SLS boosters at NASA’s Marshall Space Flight Center, and Jessica Rose, chemical engineer for SLS boosters at Northrop Grumman, will answer questions.

Through Artemis missions, NASA will land the first woman and the first person of color on the Moon, paving the way for a long-term lunar presence and serving as a steppingstone to send astronauts to Mars. Credits: NASA/Kevin O’Brien

The FSB-2 test builds off the Flight Support Booster-1 test conducted in September 2020 and will demonstrate a newly qualified motor initiation system and qualify a new ablative lining to protect the booster nozzle. This test will also provide information for the development of the next generation booster obsolescence and life extension booster that will support Artemis IX and beyond.

Through Artemis missions, NASA will land the first woman and the first person of color on the Moon, paving the way for a long-term, sustainable lunar presence and serving as a steppingstone for future astronaut missions to Mars.

Decade of Excellence: NASA Named Best Place to Work 10th Year in a Row

For the 10th consecutive year, the Partnership for Public Service has ranked NASA the Best Place to Work in the Federal Government among large agencies.

The rankings, announced July 13, reflect the agency’s continuing dedication to supporting and strengthening its workforce while also carrying out its inspirational mission of exploration and discovery for the benefit of all humanity.

“This is only possible because of the NASA family, which empowers our agency to continue achieving monumental milestones that shape history and benefit all of humanity. I am deeply proud to be a part of and represent such a creative and talented workforce,” said NASA Administrator Bill Nelson. “Despite a global pandemic, we came together to make 2021 a banner year for space exploration and discovery – from the successful launch of the James Webb Space Telescope to launching astronauts to the International Space Station from American soil. And we are poised to accomplish more daring feats with new advancements in aeronautics, more scientific contributions, and incredible technological breakthroughs, especially as our Artemis I mission paves the way for future crewed missions to the Moon and beyond.”

Jody Singer, director of NASA’s Marshall Space Flight Center, opened Marshall’s town hall July 13 by announcing the first-place ranking. “This is the 10th consecutive year that NASA has received this ranking through the Partnership for Public Service,” Singer said. “We also received the No. 1 ranking for our response to the COVID-19 pandemic. This could not be achieved without the dedication and teamwork of each of you, and for that I say ‘thank you.’”

The Best Places to Work in the federal government rankings are based on responses to the Office of Personnel Management’s annual Federal Employee Viewpoint Survey from almost 624,800 employees at 482 federal agencies and offices. The Partnership for Public Service began publishing the rankings in 2003.

For the complete list of rankings, visit here.

Dragon Docks to Space Station, Delivering Science Benefiting Humans

While the International Space Station was traveling more than 267 miles over the South Atlantic Ocean, the SpaceX Dragon cargo spacecraft autonomously docked to the forward-facing port of the station’s Harmony module July 16, with NASA astronauts Bob Hines and Jessica Watkins monitoring operations from the station.

The Dragon launched on SpaceX’s 25th contracted commercial resupply mission for NASA on July 14 from Launch Complex 39A at the agency’s Kennedy Space Center. Dragon will spend about one month attached to the space station before it returns to Earth with cargo and research.

Science experiments Dragon delivered to the space station include:

- Mapping Earth’s Dust – The Earth Surface Mineral Dust Source Investigation (EMIT), developed by NASA’s Jet Propulsion Laboratory, employs NASA imaging spectroscopy technology to measure the mineral composition of dust in Earth’s arid regions. Mineral dust blown into the air can travel significant distances and affect Earth’s climate, weather, vegetation, and more. For example, dust containing dark minerals that absorb sunlight can warm an area, while light-colored mineral dust can cool it. Blowing dust also affects air quality, surface conditions such as rate of snow melt, and phytoplankton health in the ocean. The investigation collects images for one year to generate maps of the mineral composition in the regions on Earth that produce dust. Such mapping could advance our understanding of the effects of mineral dust on human populations now and in the future.

- Speedier Immune System Aging – Aging is associated with changes in the immune response known as immunosenescence. Microgravity causes changes in human immune cells that resemble this condition but happen faster than the actual process of aging on Earth. The Immunosenescence investigation, sponsored the by International Space Station U.S. National Laboratory, uses tissue chips to study how microgravity affects immune function during flight and whether immune cells recover post-flight. Tissue chips are small devices that contain human cells in a 3D structure, allowing scientists to test how those cells respond to stresses, drugs, and genetic changes.

- Soil in space – On Earth, complex communities of microorganisms carry out key functions in soil, including cycling of carbon and other nutrients and supporting plant growth. Dynamics of Microbiomes in Space sponsored by NASA’s Division of Biological and Physical Sciences, examines how microgravity affects metabolic interactions in communities of soil microbes. This research focuses on microbe communities that decompose chitin, a natural carbon polymer on Earth.

- High school student weather study – BeaverCube is an education mission that will teach high school students aerospace science by having them design a CubeSat. BeaverCube will host one visible and two infrared imagers to measure cloud properties, ocean surface temperatures, and ocean color to study Earth’s climate and weather systems. It also will demonstrate an application for the use of shape memory alloy technology via an in-orbit calibration technique.

- Genes, no cells – Cell-free technology is a platform for producing protein without specialized equipment of living cells that need to be cultured. Genes in Space-9, sponsored by the National Lab, demonstrates cell-free production of protein in microgravity and evaluates two cell-free biosensors that can detect specific target molecules. This technology could provide a simple, portable, and low-cost tool for medical diagnostics, on-demand production of medicine and vaccines, and environmental monitoring on future space missions.

- Better concrete – Biopolymer Research for In-Situ Capabilities looks at how microgravity affects the process of creating a concrete alternative made with an organic material and on-site materials, such as lunar or Martian dust, known as a biopolymer soil composite. Using resources available where construction takes place makes it possible to increase the amount of shielding.

These are just a few of the hundreds of investigations currently being conducted aboard the orbiting laboratory in the areas of biology and biotechnology, physical sciences, and Earth and space science. Advances in these areas will help keep astronauts healthy during long-duration space travel and demonstrate technologies for future human and robotic exploration beyond low-Earth orbit to the Moon and Mars through NASA’s Artemis program.

NASA’s Marshall Space Flight Center serves as the primary space station science command post, as its payload operations team coordinates all U.S. scientific and commercial experiments.

Jacobs’ Steve Arnette is Next Mission Success Speaker

Dr. Steve Arnette, a senior vice president in Jacobs’ Critical Mission Solutions, will be the next speaker in the virtual Mission Success is in Our Hands Shared Experience Forum series July 21 at 11:30 a.m. He leads the Advanced Engineering, Research, and Operations business, which supports public and private sector clients across the aerospace, automotive, defense, and telecommunications sectors. This includes responsibility of Jacobs’ support for NASA and its exploration programs. For information on joining the meeting, visit here. The goal of Mission Success is in Our Hands is to help team members make meaningful connections between their jobs and the safety and success of NASA and Marshall Space Flight Center missions through shared experiences discussions, awards, and recognition. (NASA, Jacobs)

Marshall Joins ‘Plastic Free July’ Challenge

By Rick Smith

In an effort to reduce waste and curb the proliferation of plastic packaging, team members at NASA’s Marshall Space Flight Center are encouraged to take part in “Plastic Free July.”

The campaign, sponsored by the Plastic Free Foundation, offers homeowners and consumers tips to cut wasteful plastic packaging and find creative, renewable alternatives that can save money, better protect the environment, and even mitigate long-term health issues.

That last concern is much on the mind of Malene McElroy, Marshall’s sustainability coordinator and Environmental Management System coordinator.

“Scientists have identified microplastics in the air we breathe, the water we drink, and the food we eat,” she said. “It’s in our own best interests to reduce that amount however we can – particularly by eliminating single-use disposable items.”

Each week this month, Marshall’s “Green Team” – members of the Environmental Engineering & Occupational Health Office – encourages the workforce to assess different areas of their daily lives and look for ways to limit use of plastics. The easiest tips are well known today: avoiding single-use plastic bottles, straws, and cutlery, substituting reusable cloth or canvas bags for plastic shopping bags, and switching from plastic food storage containers to reusable glassware or other alternatives.

The campaign suggests a variety of ways to reduce plastics use in the kitchen, the bathroom, throughout the home, and during parties and holiday-themed events. Marshall team members can find these weekly tips here.

The Plastic Free July campaign also seeks to reduce greenhouse gas emissions associated with the entire plastic lifecycle, from acquisition of fossil fuels through manufacture, purchase, and disposal. Experts agree that reducing our reliance on plastic will help limit global climate change to an increase of 1.5 degrees Celsius, or 2.7 degrees Fahrenheit, by 2100. Climate scientists warn that passing that threshold will risk drought and other global climate disruptions.

“Think of it as an interactive challenge to benefit yourself and your loved ones – and also the planet we share,” McElroy said. “Hopefully, the measurable impact will help create new awareness, new habits, and new hope for a healthier, greener future.”

Plastic, which can take up to 500 years to decompose, has been in regular use for more than a century now and is ubiquitous across all walks of life. In 1950, human beings around the world produced 2.1 million tons of plastic. By 2015, that number had grown to 406 million tons.

McElroy said her team doesn’t just advocate for change; they adopt numerous tactics themselves. “We’re all very excited about changing our habits,” she said. “My family has been using cloth produce bags and aluminum straws for more than a year. This summer, we’re trying out bamboo toothbrushes and other creative tips.”

Each Wednesday in July, the Sustainability Team will host an exhibit table at the Food Truck Corral, sharing information about alternatives to single-plastic use and providing sample items to interested members of the Marshall team.

Smith, a Manufacturing Technical Solutions employee, supports Marshall’s Office of Strategic Analysis & Communications.