Sustainable aircraft of the future are going to need propulsion systems that can use technology to generate power comparable to the equipment used in today’s commercial jets.

But creating such a complex system comes with a serious challenge: How do you safely test it under the high-altitude conditions where it would need to operate?

One NASA facility, safely on the ground in Ohio, offers that very solution.

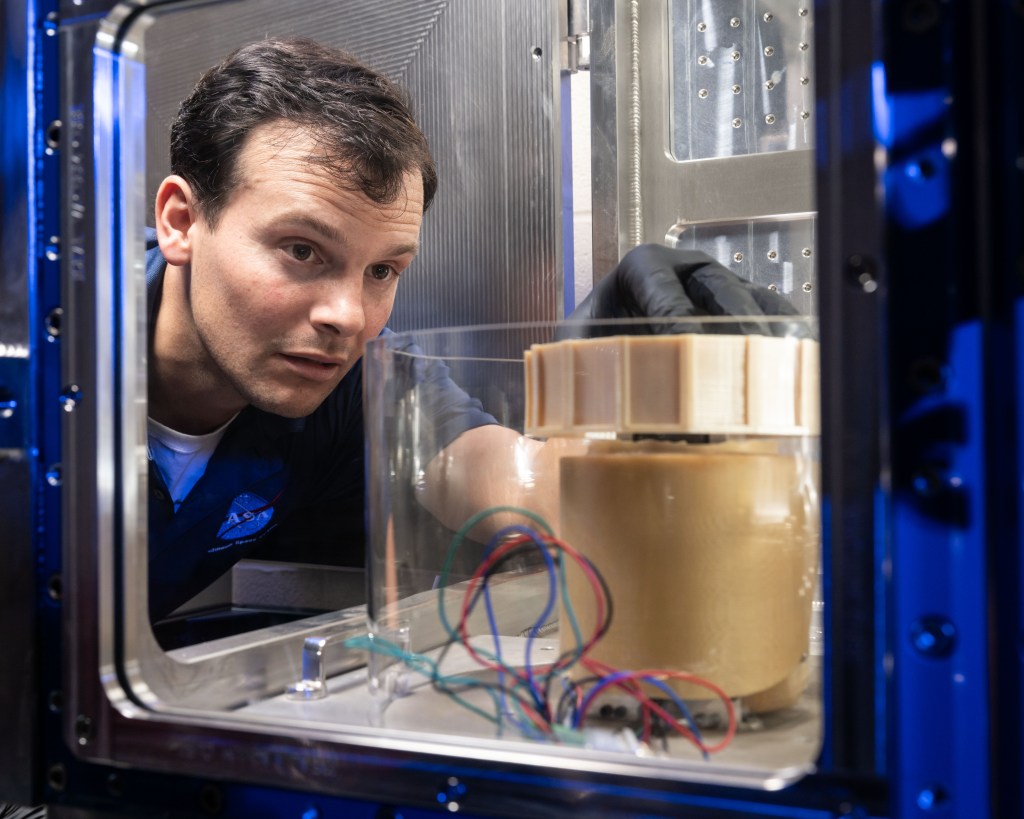

Located at the agency’s Neil A. Armstrong Test Facility in Sandusky, Ohio, NASA’s Electric Aircraft Testbed (NEAT) allows U.S. technology developers from industry, academia, and government to take experimental aircraft power systems through their design, development, assembly, and test phases.

“There are many technical challenges associated with building and testing hybrid-electric propulsion systems,” said Bob Pearce, associate administrator for NASA’s Aeronautics Research Mission Directorate.

So, when engineers at GE Aviation sought to test its megawatt-class, multi-kilovolt hybrid electric propulsion system – designed to be powerful enough for a single-aisle commercial airliner – NEAT had the capabilities they needed.

“GE is incredibly proud to have partnered with NASA for decades on pioneering new aviation technologies that make propulsion safer, quieter and more sustainable,” said Mohamed Ali, vice president and general manager of engineering for GE.

Operated by NASA’s Glenn Research Center in Cleveland, NEAT is unique among other aeronautical laboratories because it features the ability to test full-scale propulsion systems at simulated high altitudes.

“NEAT and the experts at NASA Glenn allow us to perform tests without ever leaving the ground. This capability significantly reduces safety risks and costs,” Pearce said.

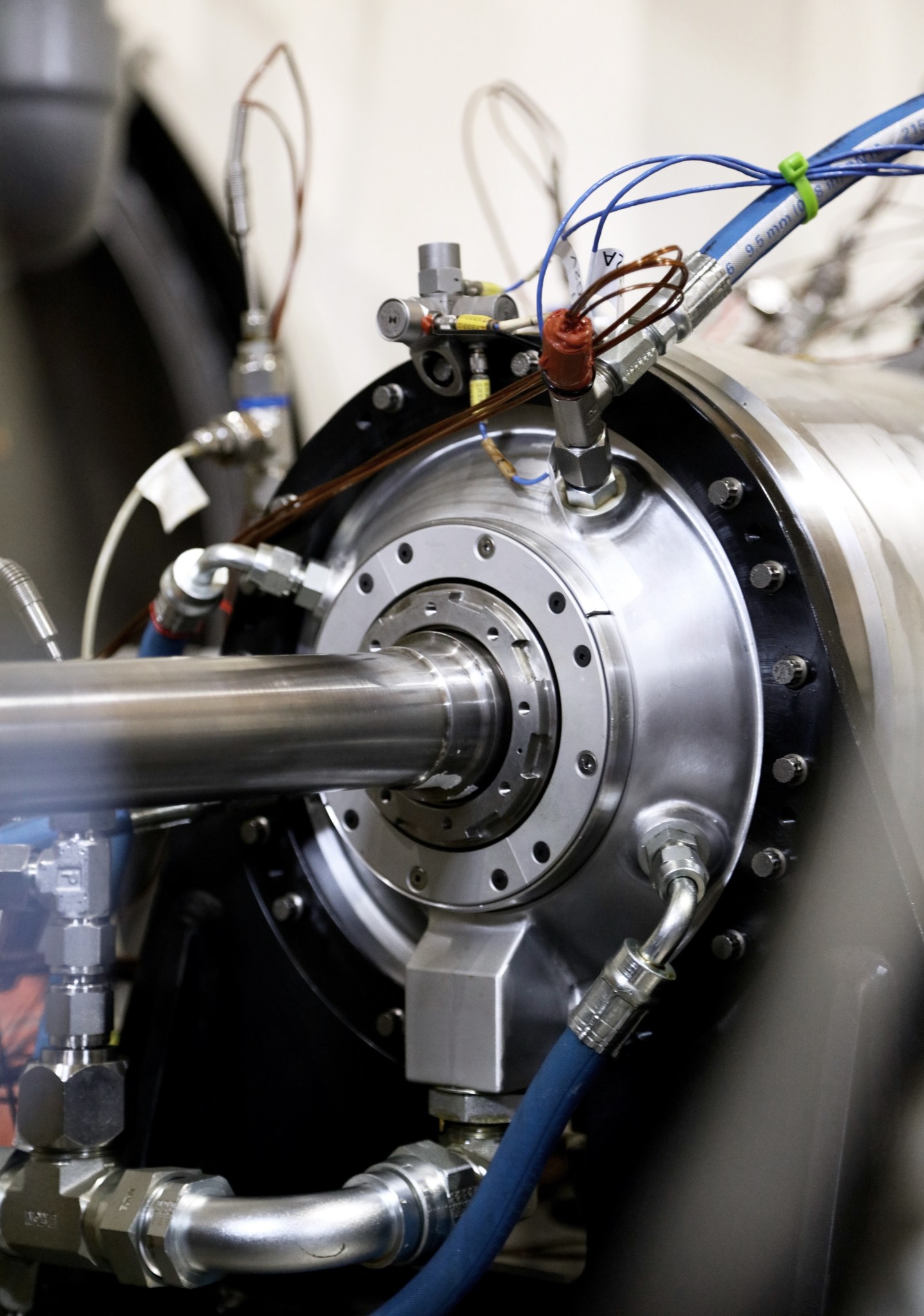

GE’s system includes power control systems, electric motors, power converters, and power transmissions.

These components must be tested together at simulated altitude because of issues that can affect electrical system performance in flight, but not at ground level. That’s why NEAT’s capabilities are so important.

GE began its test campaign in 2019 and scaled it up though the addition of megawatt-class motors, generators, and converters.

Its final hurdle, the altitude integration testing, launched in 2021. Using NEAT’s large altitude chamber, test personnel operated two sets of complete hybrid electric systems representing the right and left engines of an aircraft at a flight level up to 45,000 feet.

“Together, we reached a historic testing milestone of a high power, high voltage hybrid electric integrated system operating at altitude conditions in NASA’s NEAT facility,” Ali said. “The successful completion of this testing has positioned us well for continued development of a megawatt-class hybrid-electric propulsion system.”

The tests were the culmination of years work under a Space Act Agreement between GE and NASA to use the NEAT facility.

With ground testing complete, NASA and GE will now transition to flight testing under the agency’s Electrified Powertrain Flight Demonstration project, which seeks to introduce electrified aircraft propulsion technologies to the U.S. commercial short-range and regional aviation markets during the next decade.

The successful high-power, high-voltage test with GE is just one piece of NASA’s broader efforts to develop a suite of technologies in support of climate change initiatives, and eventually, actual electric propulsion flight tests.